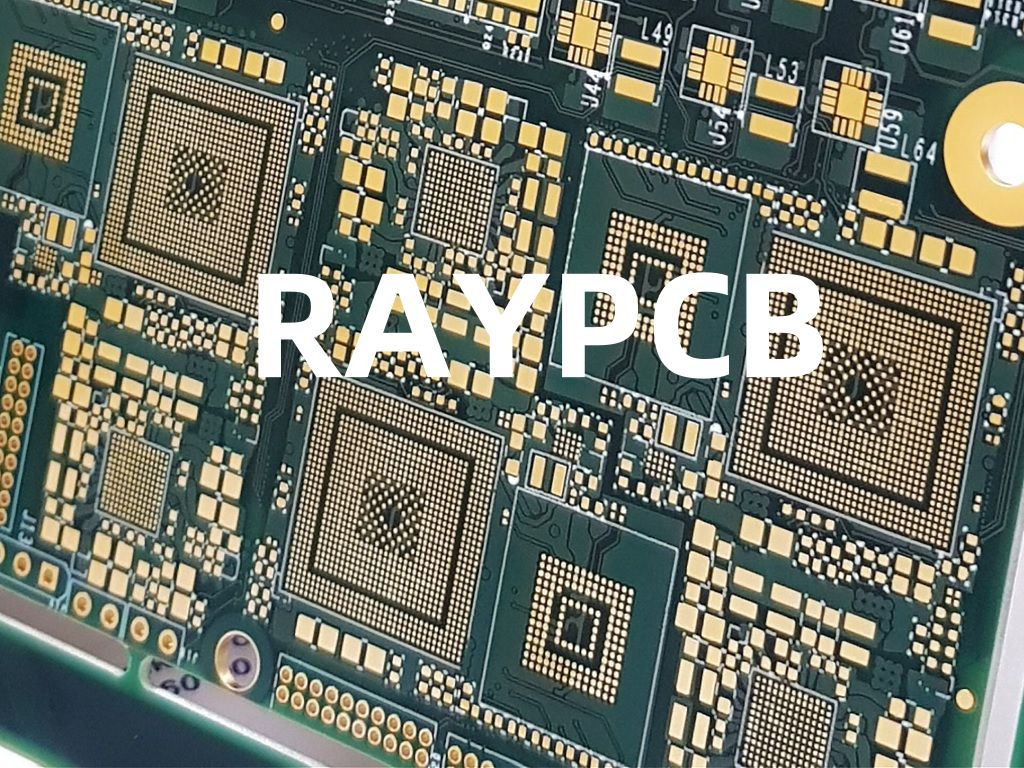

What are HDI PCBs?

HDI (High Density Interconnector) PCBs are printed circuit boards that feature a higher wiring density per unit area compared to conventional PCBs. This is achieved through the use of smaller vias, finer trace widths, and tighter spacing between components. HDI PCBs allow for more complex designs within a smaller footprint, making them ideal for applications that require miniaturization and high performance, such as smartphones, tablets, wearable devices, and advanced medical equipment.

Key Features of HDI PCBs

- Micro vias: HDI PCBs utilize micro vias, which are small holes drilled through one or more layers of the PCB to create interconnections between layers. These vias typically have a diameter of less than 150 microns (µm) and can be filled with conductive material or left unfilled, depending on the design requirements.

- Fine trace widths and spacing: The trace widths and spacing on HDI PCBs are significantly smaller than those on traditional PCBs. Trace widths can be as narrow as 50 µm, while the spacing between traces can be as low as 50 µm. This allows for a higher density of interconnections within a given area.

- Multilayer construction: HDI PCBs often have a higher layer count than conventional PCBs, with some designs incorporating up to 16 or more layers. This multilayer construction enables more complex routing and better signal integrity.

- Blind and buried vias: In addition to micro vias, HDI PCBs may also feature blind and buried vias. Blind vias connect an outer layer to an inner layer, while buried vias connect two or more inner layers without reaching the outer layers. These types of vias help to further increase the density of interconnections and optimize the use of available space.

Benefits of HDI PCBs

Miniaturization

One of the primary benefits of HDI PCBs is their ability to enable miniaturization of electronic devices. With the increasing demand for smaller, more compact devices, HDI technology allows designers to pack more functionality into a smaller space. This is particularly important for portable devices, such as smartphones and wearables, where size and weight are critical factors.

Improved Signal Integrity

HDI PCBs offer improved signal integrity compared to traditional PCBs. The shorter interconnections and reduced layer-to-layer transitions result in lower signal losses, reduced crosstalk, and better overall signal quality. This is particularly important for high-speed applications, such as 5G networks and high-performance computing, where signal integrity is crucial for optimal performance.

Enhanced Thermal Management

The higher density of components on HDI PCBs can lead to increased heat generation. However, HDI designs can incorporate advanced thermal management techniques, such as the use of thermal vias and high-conductivity materials, to efficiently dissipate heat and maintain optimal operating temperatures. This helps to ensure the reliability and longevity of the electronic device.

Cost Reduction

Although the initial design and fabrication costs for HDI PCBs may be higher than those for conventional PCBs, the overall cost of the end product can be lower. This is because HDI technology enables the integration of multiple functions onto a single board, reducing the need for separate components and assemblies. Additionally, the smaller form factor of HDI PCBs can lead to reduced material costs and more efficient use of manufacturing resources.

HDI PCB Design Considerations

Layer Stack-up

The layer stack-up is a critical aspect of HDI PCB design. It defines the arrangement of conductive layers, insulating layers, and vias within the PCB. The stack-up must be carefully designed to ensure proper signal routing, impedance control, and electromagnetic compatibility (EMC). Some common HDI layer stack-ups include:

- 1+N+1: This stack-up consists of a core layer (N) sandwiched between two build-up layers (1+1). The build-up layers contain micro vias, while the core layer may contain through-hole vias.

- 2+N+2: This stack-up features two build-up layers on each side of the core layer, providing additional routing flexibility and signal integrity.

- 3+N+3: This stack-up offers even greater routing density and signal integrity, with three build-up layers on each side of the core layer.

Via Types and Placement

The selection and placement of vias are crucial for HDI PCB design. Micro vias are the most common type used in HDI designs, but blind and buried vias may also be employed to optimize routing and reduce layer count. Via placement should be carefully considered to minimize signal reflections, crosstalk, and EMI. Additionally, via-in-pad technology, where components are mounted directly on top of vias, can be used to further increase component density.

Materials Selection

The choice of materials for HDI PCBs is important for ensuring optimal performance and reliability. The substrate material should have a low dielectric constant (Dk) and dissipation factor (Df) to minimize signal losses and maintain signal integrity. Common substrate materials for HDI PCBs include FR-4, polyimide, and high-frequency laminates such as Rogers RO4000 series. The copper foil used for the conductive layers should be of high quality and have a low profile to enable fine trace widths and spacing.

Manufacturing Process for HDI PCBs

The manufacturing process for HDI PCBs is more complex than that for traditional PCBs due to the smaller features and tighter tolerances involved. The key steps in the HDI PCB manufacturing process include:

- Inner layer fabrication: The inner layers of the PCB are fabricated using standard PCB manufacturing techniques, such as photolithography and etching.

- Lamination: The inner layers are laminated together with insulating layers (prepregs) under high temperature and pressure to form the core of the PCB.

- Drilling: Micro vias are drilled through the build-up layers using laser or mechanical drilling techniques. Blind and buried vias may also be drilled at this stage.

- Plating: The vias are plated with a conductive material, typically copper, to create electrical connections between layers.

- Patterning: The outer layers of the PCB are patterned using photolithography and etching to create the final circuit pattern.

- Surface finish: A surface finish, such as ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative), is applied to protect the exposed copper and enhance solderability.

- Electrical testing: The completed HDI PCB undergoes rigorous electrical testing to ensure functionality and reliability.

Applications of HDI PCBs

HDI PCBs find applications in a wide range of industries and products, including:

- Smartphones and tablets

- Wearable devices, such as smartwatches and fitness trackers

- Medical devices, such as implantable sensors and diagnostic equipment

- Automotive electronics, including advanced driver assistance systems (ADAS) and infotainment systems

- Aerospace and defense applications, such as avionics and satellite communication systems

- Industrial automation and control systems

- High-performance computing and data centers

As electronic devices continue to become smaller, more powerful, and more feature-rich, the demand for HDI PCBs is expected to grow. RAYPCB, a leading PCB manufacturer, is well-positioned to meet this demand with its state-of-the-art HDI PCB fabrication capabilities.

FAQ

- What is the minimum trace width and spacing achievable with HDI PCBs?

The minimum trace width and spacing for HDI PCBs can be as low as 50 µm (2 mil). However, the specific capabilities may vary depending on the PCB manufacturer and the design requirements. - How many layers can an HDI PCB have?

HDI PCBs can have up to 16 or more layers, depending on the complexity of the design and the manufacturing capabilities of the PCB fabricator. - What is the difference between blind and buried vias?

Blind vias connect an outer layer to an inner layer of the PCB, while buried vias connect two or more inner layers without reaching the outer layers. - Are HDI PCBs more expensive than traditional PCBs?

The initial design and fabrication costs for HDI PCBs may be higher than those for traditional PCBs due to the more complex manufacturing process and tighter tolerances. However, the overall cost of the end product can be lower because HDI technology enables the integration of multiple functions onto a single board, reducing the need for separate components and assemblies. - What industries commonly use HDI PCBs?

HDI PCBs are commonly used in industries that require high-performance, compact electronic devices, such as consumer electronics (smartphones, tablets, wearables), medical devices, automotive electronics, aerospace and defense, industrial automation, and high-performance computing.

| Parameter | HDI PCBs | Traditional PCBs |

|---|---|---|

| Trace width | As low as 50 µm (2 mil) | Typically 100 µm (4 mil) or larger |

| Trace spacing | As low as 50 µm (2 mil) | Typically 100 µm (4 mil) or larger |

| Via diameter | Less than 150 µm (6 mil) | Typically 200 µm (8 mil) or larger |

| Layer count | Up to 16 or more layers | Typically 4 to 8 layers |

| Blind and buried vias | Commonly used | Less common |

In conclusion, HDI PCBs offer numerous advantages over traditional PCBs, including miniaturization, improved signal integrity, enhanced thermal management, and potential cost reduction. As the demand for smaller, high-performance electronic devices continues to grow, HDI technology will play an increasingly important role in the electronics industry. RAYPCB, with its expertise in HDI PCB fabrication, is well-positioned to support customers in developing cutting-edge electronic products that leverage the benefits of HDI technology.

No responses yet