Introduction to PCB Prototypes

Printed Circuit Board (PCB) prototypes are essential for testing and validating the design of electronic circuits before mass production. A PCB prototype is a preliminary version of the final product, which allows engineers and designers to test the functionality, reliability, and performance of the circuit. In this article, we will discuss everything you need to know about PCB prototype services, including the benefits, process, and factors to consider when choosing a service provider.

What is a PCB Prototype?

A PCB prototype is a physical representation of the designed circuit board, which is created to test and verify the functionality of the circuit before mass production. It is a crucial step in the product development process, as it allows engineers to identify and fix any issues or errors in the design, ensuring that the final product meets the required specifications and standards.

Benefits of PCB Prototyping

PCB prototyping offers several benefits, including:

- Cost-effective: PCB prototyping allows you to test and validate your design before investing in mass production, reducing the risk of costly errors and redesigns.

- Time-saving: By identifying and fixing issues early in the development process, PCB prototyping can help you save time and accelerate your time-to-market.

- Improved quality: PCB prototyping allows you to test and refine your design, ensuring that the final product is of high quality and meets the required specifications.

- Enhanced functionality: By testing the functionality of your circuit board, PCB prototyping can help you optimize your design and enhance the overall performance of your product.

The PCB Prototyping Process

The PCB prototyping process typically involves the following steps:

1. Design

The first step in the PCB prototyping process is to design the circuit board using specialized software such as Altium, Eagle, or KiCad. The design should include all the necessary components, traces, and connections required for the circuit to function properly.

2. Fabrication

Once the design is complete, the next step is to fabricate the PCB prototype. This involves creating a physical representation of the circuit board using various materials such as copper, fiberglass, and solder mask. The fabrication process can be done using different methods, such as:

- Etching: This method involves removing unwanted copper from the board using chemicals, leaving only the desired traces and connections.

- Milling: This method uses a computer-controlled machine to remove unwanted copper from the board, creating the desired traces and connections.

- 3D printing: This method involves printing the PCB using a specialized 3D printer that can create conductive traces and connections.

3. Assembly

After the PCB prototype is fabricated, the next step is to assemble the components onto the board. This can be done manually or using automated equipment, depending on the complexity of the circuit and the number of components required.

4. Testing

Once the PCB prototype is assembled, it needs to be tested to ensure that it functions as intended. This involves running various tests such as continuity, functionality, and stress tests to identify any issues or errors in the design.

5. Refinement

Based on the results of the testing phase, the PCB prototype may need to be refined or redesigned to address any issues or improve its performance. This process may involve multiple iterations until the desired results are achieved.

Factors to Consider When Choosing a PCB Prototype Service

When choosing a PCB prototype service, there are several factors to consider, including:

1. Quality

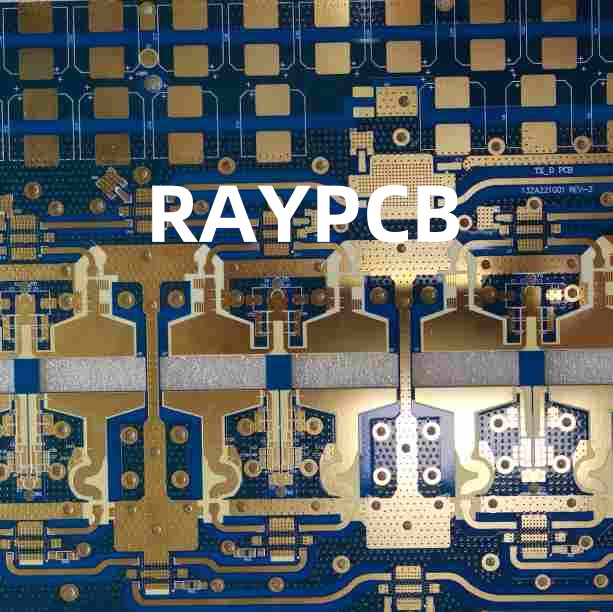

The quality of the PCB prototype is crucial, as it directly impacts the performance and reliability of the final product. Look for a service provider that uses high-quality materials and advanced manufacturing techniques to ensure that your prototype meets the highest standards of quality.

2. Turnaround Time

The turnaround time for PCB prototyping can vary depending on the complexity of the design and the service provider. Look for a provider that offers fast turnaround times without compromising on quality, so you can get your prototype quickly and move on to the next stage of product development.

3. Cost

The cost of PCB prototyping can vary depending on the complexity of the design, the materials used, and the service provider. Look for a provider that offers competitive pricing without compromising on quality, so you can get the best value for your money.

4. Expertise

Look for a PCB prototype service provider that has a team of experienced engineers and technicians who can provide expert advice and support throughout the prototyping process. They should be able to answer your questions, provide guidance on design optimization, and help you troubleshoot any issues that may arise.

5. Capabilities

Different PCB prototype service providers may have different capabilities, such as the ability to handle complex designs, use advanced materials, or provide additional services such as assembly and testing. Look for a provider that has the capabilities you need to ensure that your prototype meets your specific requirements.

PCB Prototyping vs. PCB Manufacturing

While PCB prototyping and PCB manufacturing are both essential steps in the product development process, they serve different purposes and have different requirements.

| PCB Prototyping | PCB Manufacturing |

|---|---|

| Used for testing and validation | Used for mass production |

| Small quantities (1-100) | Large quantities (100+) |

| Fast turnaround time (1-2 weeks) | Longer lead time (4-8 weeks) |

| Higher cost per unit | Lower cost per unit |

| Flexible design changes | Fixed design |

PCB Prototype Service Providers

There are many PCB prototype service providers available in the market, each with their own strengths and capabilities. Some of the top providers include:

1. PCBWay

PCBWay is a leading PCB prototype service provider that offers high-quality prototypes at competitive prices. They have a team of experienced engineers who can provide expert advice and support throughout the prototyping process, and they offer a wide range of capabilities, including advanced materials and assembly services.

2. Seeed Studio

Seeed Studio is another popular PCB prototype service provider that offers fast turnaround times and high-quality prototypes. They have a user-friendly online platform that allows you to easily upload your design files and get an instant quote, and they offer a variety of additional services such as component sourcing and assembly.

3. OSH Park

OSH Park is a community-driven PCB prototype service provider that offers high-quality prototypes at affordable prices. They have a unique model where they combine multiple designs onto a single panel to reduce costs, and they offer a variety of materials and finishes to choose from.

Frequently Asked Questions (FAQ)

1. How long does it take to get a PCB prototype?

The turnaround time for PCB prototyping can vary depending on the complexity of the design and the service provider, but it typically ranges from 1-2 weeks.

2. How much does PCB prototyping cost?

The cost of PCB prototyping can vary depending on the complexity of the design, the materials used, and the service provider. It can range from a few dollars to several hundred dollars per prototype.

3. What files do I need to provide for PCB prototyping?

To get a PCB prototype, you typically need to provide the following files:

- Gerber files: These are the files that describe the layout of the PCB, including the copper layers, solder mask, and silkscreen.

- Drill files: These are the files that describe the location and size of the holes in the PCB.

- Bill of Materials (BOM): This is a list of all the components required for the assembly of the PCB.

- Assembly drawings: These are the drawings that show how the components should be assembled onto the PCB.

4. Can I get a PCB prototype with custom colors and finishes?

Yes, many PCB prototype service providers offer a variety of custom colors and finishes, such as matte black, green solder mask, or gold plating. However, these options may come at an additional cost.

5. What if I need to make changes to my PCB prototype?

If you need to make changes to your PCB prototype, most service providers offer a revision service where they can modify your design and fabricate a new prototype based on your feedback. However, this may come at an additional cost and may impact the turnaround time.

Conclusion

PCB prototyping is an essential step in the product development process, as it allows you to test and validate your design before investing in mass production. When choosing a PCB prototype service provider, it’s important to consider factors such as quality, turnaround time, cost, expertise, and capabilities to ensure that you get the best value for your money.

By following the PCB prototyping process and working with a reputable service provider, you can create high-quality prototypes that meet your specific requirements and help you bring your product to market faster and with greater confidence.

No responses yet