1. Understanding the PCB Design Flow

The PCB design flow is a systematic approach to designing and manufacturing printed circuit boards. It involves several stages, including:

- Schematic design

- PCB layout

- Design rule check (DRC)

- Gerber file generation

- PCB fabrication

- PCB assembly

- Testing and validation

Understanding each stage of the PCB design flow is crucial for creating high-quality prototypes.

2. Defining PCB Requirements

Before starting the PCB design process, it is essential to define the requirements for your PCB. This includes:

- Functional requirements: What does the PCB need to do?

- Electrical requirements: What are the voltage, current, and power requirements?

- Mechanical requirements: What are the size, shape, and mounting requirements?

- Environmental requirements: What are the operating temperature, humidity, and vibration requirements?

Clearly defining these requirements will help guide the design process and ensure that your prototype meets your needs.

3. Schematic Design

The schematic design is the first step in the PCB design process. It involves creating a diagram that shows the electrical connections between components. The schematic should include:

- Component symbols

- Reference designators

- Net names

- Power and ground connections

Using a schematic capture tool, such as Eagle or KiCad, can simplify the schematic design process and help ensure accuracy.

4. PCB Layout

Once the schematic is complete, the next step is to create the PCB layout. This involves arranging the components on the board and routing the traces between them. Some key considerations for PCB layout include:

- Component placement: Components should be placed to minimize trace lengths and crossing, and to allow for proper airflow and heat dissipation.

- Trace routing: Traces should be routed to minimize crosstalk and electromagnetic interference (EMI), and to ensure signal integrity.

- Via placement: Vias should be placed strategically to minimize the number of layers needed and to improve manufacturability.

Using a PCB layout tool, such as Eagle or Altium Designer, can help streamline the layout process and ensure that your design meets manufacturing requirements.

5. Design Rule Check (DRC)

Before generating Gerber files for manufacturing, it is important to run a design rule check (DRC) on your PCB layout. The DRC checks for violations of the design rules specified by the PCB manufacturer, such as minimum trace width, minimum clearance between traces, and minimum drill size.

Running a DRC can help identify potential manufacturing issues early in the design process, saving time and money later on.

6. Gerber File Generation

Once the PCB layout is complete and has passed the DRC, the next step is to generate Gerber files for manufacturing. Gerber files are the industry standard format for describing PCB layouts and are used by PCB manufacturers to fabricate the board.

Gerber files typically include:

- Top and bottom copper layers

- Solder mask layers

- Silkscreen layers

- Drill files

It is important to carefully review the Gerber files before sending them to the manufacturer to ensure that they accurately represent your design intent.

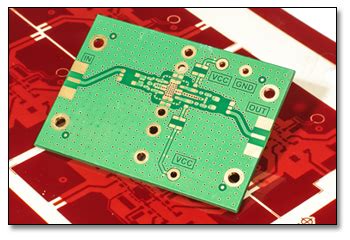

7. PCB Fabrication

PCB fabrication is the process of manufacturing the physical PCB based on the Gerber files. The fabrication process typically involves the following steps:

- Substrate preparation: The substrate material (usually FR-4) is cut to size and cleaned.

- Copper deposition: A thin layer of copper is deposited onto the substrate using electroplating or foil lamination.

- Photoresist application: A photosensitive resist is applied to the copper layer.

- Exposure and development: The photoresist is exposed to UV light through a photomask and then developed, leaving a pattern of exposed copper.

- Etching: The exposed copper is etched away using a chemical solution, leaving only the desired traces.

- Soldermask application: A layer of soldermask is applied to protect the copper traces and prevent shorts.

- Silkscreen application: A layer of silkscreen is applied to add labels and markings to the board.

- Drilling: Holes are drilled through the board for through-hole components and vias.

- Surface finish application: A surface finish, such as HASL or ENIG, is applied to protect the copper and improve solderability.

Choosing a reputable PCB manufacturer with experience in prototyping can help ensure that your boards are fabricated to your specifications and meet your quality requirements.

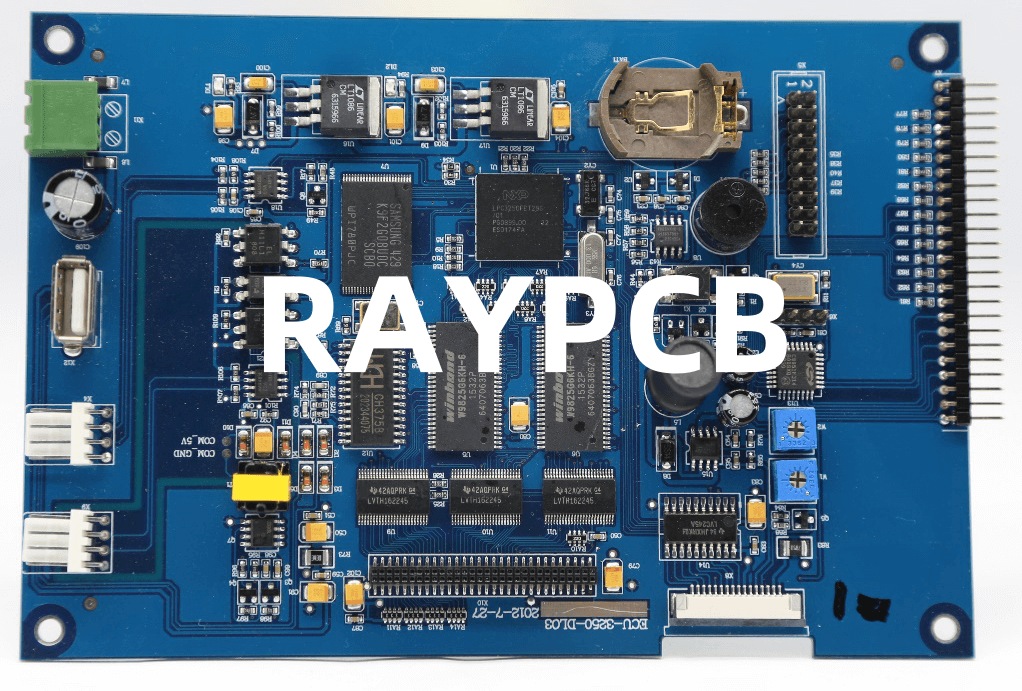

8. PCB Assembly

Once the PCB has been fabricated, the next step is to assemble the components onto the board. PCB assembly can be done manually or using automated equipment, depending on the complexity of the board and the quantity being produced.

Some key considerations for PCB assembly include:

- Component placement: Components should be placed accurately and securely on the board, with proper orientation and alignment.

- Soldering: Components should be soldered using the appropriate technique (e.g., reflow or wave soldering) and temperature profile to ensure reliable connections.

- Inspection: Assembled boards should be visually inspected and tested to ensure proper functionality and quality.

Choosing an experienced PCB assembly provider can help ensure that your prototypes are assembled correctly and meet your performance requirements.

9. Testing and Validation

The final step in the PCB Prototyping process is testing and validation. This involves verifying that the assembled board meets your functional, electrical, and mechanical requirements.

Some common testing methods include:

- In-circuit testing (ICT): Verifies that each component on the board is properly connected and functioning.

- Functional testing: Verifies that the board performs its intended function under various operating conditions.

- Environmental testing: Verifies that the board can withstand the expected environmental conditions, such as temperature, humidity, and vibration.

- Electromagnetic compatibility (EMC) testing: Verifies that the board does not emit excessive electromagnetic interference and is not susceptible to external interference.

Thorough testing and validation can help identify any issues with your prototype and ensure that it meets your performance and reliability requirements.

Frequently Asked Questions (FAQ)

1. What is the difference between a PCB Prototype and a production PCB?

A PCB prototype is a small batch of boards used for testing and validation, while a production PCB is a larger batch of boards used for final product manufacturing. Prototypes may have looser tolerances and may not include all the features of a production board.

2. How long does it take to manufacture a PCB prototype?

The lead time for PCB prototyping can vary depending on the complexity of the board and the manufacturer’s workload. Typical lead times range from a few days to a few weeks.

3. What are some common PCB surface finishes?

Common PCB surface finishes include:

- Hot air solder leveling (HASL): A tin-lead alloy is applied to the copper traces and then leveled using hot air.

- Electroless nickel immersion gold (ENIG): A layer of nickel is applied to the copper, followed by a thin layer of gold.

- Immersion silver (IAg): A thin layer of silver is applied to the copper traces.

- Organic solderability preservative (OSP): A thin, organic coating is applied to the copper to protect it from oxidation.

4. What is the typical cost of a PCB prototype?

The cost of a PCB prototype can vary widely depending on the size, complexity, and quantity of the boards. Typical costs range from a few hundred to a few thousand dollars.

5. What are some common PCB Design Mistakes to avoid?

Some common PCB design mistakes to avoid include:

- Incorrect component footprints

- Insufficient clearance between traces

- Inadequate power and ground routing

- Lack of proper termination for high-speed signals

- Inconsistent or incorrect labeling and markings

By understanding the fundamentals of PCB prototyping and the PCB design flow, you can create successful prototypes that meet your performance, reliability, and cost requirements. Remember to carefully define your requirements, follow best practices for schematic design and PCB layout, and thoroughly test and validate your prototypes before moving into production. With careful planning and attention to detail, you can bring your electronic product ideas to life.

No responses yet