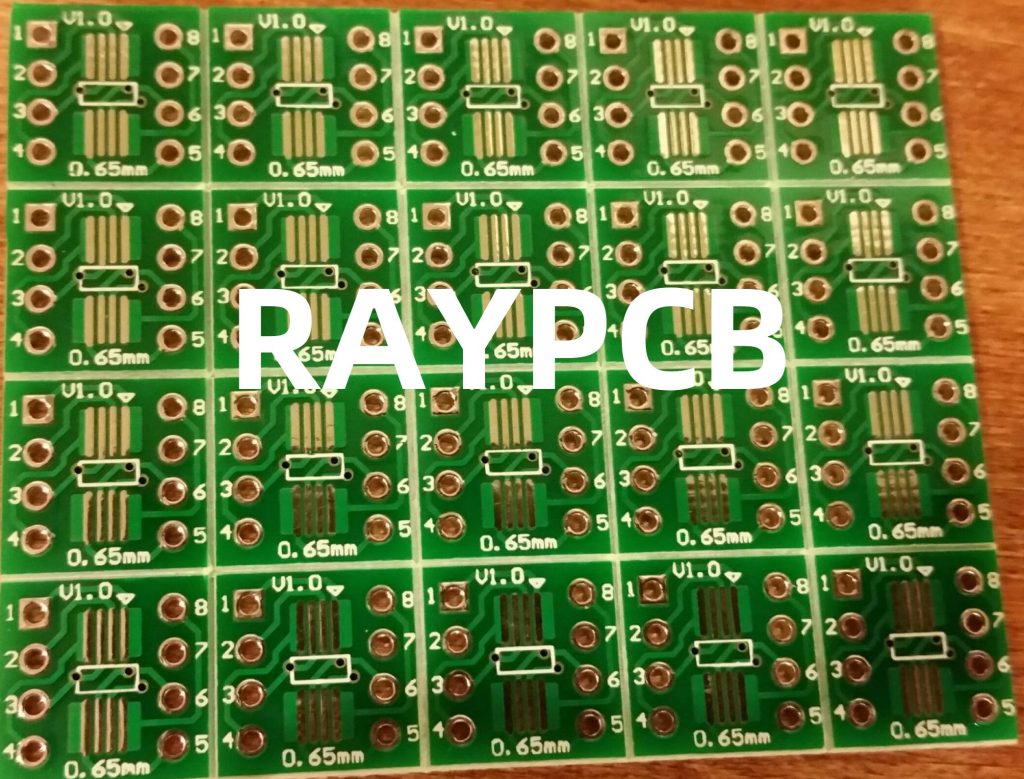

What is a PCB Prototype?

A PCB (Printed Circuit Board) prototype is a preliminary version of a circuit board that is used for testing and validation purposes. It is a physical representation of the designed circuit, which includes all the necessary components, such as resistors, capacitors, and integrated circuits (ICs), mounted on a non-conductive substrate.

PCB prototypes are typically fabricated in small quantities, ranging from a single unit to a few dozen, depending on the complexity of the design and the testing requirements. They are used to verify the functionality, performance, and reliability of the circuit before proceeding with mass production.

Types of PCB Prototypes

There are several types of PCB prototypes, each with its own characteristics and applications:

- Single-sided PCB: This type of PCB has conductive traces on only one side of the substrate. It is the simplest and most cost-effective option for basic circuit designs.

- Double-sided PCB: As the name suggests, double-sided PCBs have conductive traces on both sides of the substrate. They offer higher component density and more complex routing compared to single-sided PCBs.

- Multi-layer PCB: Multi-layer PCBs consist of three or more conductive layers separated by insulating layers. They are used for high-density, complex circuits that require advanced signal integrity and EMI (Electromagnetic Interference) control.

- Flexible PCB: Flexible PCBs are made from flexible materials, such as polyimide, which allow them to bend and conform to various shapes. They are commonly used in wearable devices, medical equipment, and aerospace applications.

- Rigid-Flex PCB: Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs. They consist of rigid sections connected by flexible sections, enabling 3D packaging and improved reliability in high-stress environments.

The Importance of PCB Prototyping

PCB prototyping plays a crucial role in the product development process. It allows designers and engineers to:

- Verify functionality: Prototypes enable you to test the functionality of your circuit design in real-world conditions. You can ensure that all components are working as intended and that the circuit performs according to specifications.

- Identify design flaws: Building a prototype helps identify any design flaws or weaknesses in the circuit. You can detect and fix issues related to signal integrity, power distribution, and component placement before proceeding with mass production.

- Optimize performance: Prototyping allows you to fine-tune and optimize the performance of your circuit. You can experiment with different component values, layouts, and routing strategies to achieve the desired performance characteristics.

- Test for reliability: Prototypes can be subjected to various stress tests, such as thermal cycling, vibration, and humidity exposure, to assess the reliability and durability of the circuit under different environmental conditions.

- Validate manufacturability: Building a prototype helps validate the manufacturability of your design. You can identify any challenges related to component sourcing, assembly processes, and testing procedures, ensuring a smooth transition to mass production.

PCB Prototyping Process

The PCB prototyping process typically involves the following steps:

- Design: The first step is to create a schematic diagram and a PCB layout using CAD (Computer-Aided Design) software. The schematic represents the logical connections between components, while the PCB layout defines the physical placement and routing of components on the board.

- Fabrication: Once the design is finalized, the PCB prototype is fabricated using various manufacturing processes, such as etching, drilling, and plating. The choice of fabrication method depends on the complexity of the design and the desired turnaround time.

- Assembly: After fabrication, the PCB prototype is populated with components using manual or automated assembly techniques. Surface mount technology (SMT) and through-hole technology (THT) are the most common assembly methods.

- Testing: The assembled prototype undergoes rigorous testing to verify its functionality, performance, and reliability. This may include functional testing, boundary scan testing, and environmental testing.

- Iteration: Based on the test results, the design may be modified and refined to address any issues or improve performance. Multiple iterations of the prototype may be necessary before finalizing the design for mass production.

Benefits of PCB Prototyping

PCB prototyping offers numerous benefits for product development teams:

- Reduced time-to-market: Prototyping allows you to identify and address design issues early in the development process, reducing the overall time-to-market for your product.

- Cost savings: By catching design flaws and optimizing performance during the prototyping phase, you can avoid costly rework and redesign during mass production.

- Improved product quality: Prototyping enables you to thoroughly test and validate your design, resulting in a higher-quality final product with fewer defects and better reliability.

- Risk mitigation: Building prototypes helps mitigate risks associated with new product development, such as technical feasibility, manufacturability, and market acceptance.

- Investor and customer confidence: Having a functional prototype can boost investor and customer confidence in your product, as it demonstrates the viability and potential of your design.

Choosing a PCB Prototype Manufacturer

When selecting a PCB prototype manufacturer, consider the following factors:

- Capabilities: Ensure that the manufacturer has the necessary capabilities to fabricate and assemble your specific PCB design, including the required layer count, material selection, and component technology.

- Turnaround time: Look for a manufacturer that offers fast turnaround times for prototyping, as this can significantly impact your product development timeline.

- Quality control: Choose a manufacturer with robust quality control processes, such as automated optical inspection (AOI) and X-ray inspection, to ensure the highest quality of your prototypes.

- Customer support: Select a manufacturer with responsive and knowledgeable customer support, as you may need assistance with design reviews, manufacturability assessments, and technical queries.

- Pricing: Compare pricing from multiple manufacturers, but keep in mind that the lowest price may not always provide the best value in terms of quality, reliability, and service.

| Factor | Importance | Description |

|---|---|---|

| Capabilities | High | Manufacturer should support your specific PCB design requirements |

| Turnaround time | High | Fast turnaround times are crucial for timely product development |

| Quality control | High | Robust quality control processes ensure high-quality prototypes |

| Customer support | Medium | Responsive and knowledgeable support can assist with various aspects of prototyping |

| Pricing | Medium | Competitive pricing is important, but should be balanced with quality and service |

FAQ

- What is the difference between a PCB prototype and a production PCB?

A PCB prototype is a preliminary version of a circuit board used for testing and validation, while a production PCB is the final version used for mass manufacturing. Prototypes are typically fabricated in small quantities with more flexible design rules, while production PCBs are optimized for high-volume manufacturing and must adhere to stricter design guidelines. - How long does it take to get a PCB prototype?

The turnaround time for a PCB prototype depends on various factors, such as the complexity of the design, the chosen fabrication method, and the manufacturer’s capacity. Typical turnaround times range from a few days to a few weeks. Some manufacturers offer expedited services for faster delivery. - What is the cost of a PCB prototype?

The cost of a PCB prototype varies depending on the size, complexity, and quantity of the boards. Other factors, such as the chosen material, layer count, and assembly requirements, also impact the price. Prototype costs can range from a few hundred to several thousand dollars, depending on these factors. - Can I use a PCB prototype for low-volume production?

In some cases, PCB prototypes can be used for low-volume production, especially if the design is relatively simple and the quantity required is small. However, it is essential to discuss your specific requirements with the manufacturer to ensure that the prototypes meet your production needs. - What files do I need to provide for PCB prototyping?

To start the PCB prototyping process, you typically need to provide the following files: - Schematic diagram (usually in PDF format)

- PCB layout (Gerber files)

- Bill of Materials (BOM)

- Assembly instructions (if applicable)

Some manufacturers may also require additional files, such as pick-and-place files or 3D models, depending on the complexity of the design and the assembly requirements.

Conclusion

PCB prototyping is a critical step in the product development process, enabling designers and engineers to test, validate, and optimize their circuit designs before mass production. By building prototypes, you can identify design flaws, improve performance, and ensure the reliability and manufacturability of your product.

When choosing a PCB prototype manufacturer, consider factors such as capabilities, turnaround time, quality control, customer support, and pricing. By selecting the right partner for your prototyping needs, you can accelerate your product development timeline, reduce risks, and ultimately bring a high-quality product to market.

No responses yet