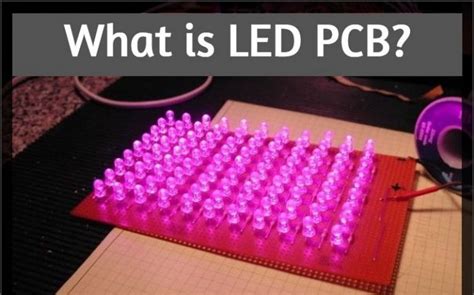

What are LED PCBs?

LED PCBs are specialized printed circuit boards designed to support and connect LEDs (Light Emitting Diodes) in a circuit. These boards provide a stable platform for mounting LEDs and ensure proper electrical connections, heat dissipation, and mechanical support. LED PCBs can be customized to accommodate different numbers, sizes, and types of LEDs, depending on the specific application requirements.

Types of LED PCBs

There are several types of LED PCBs, each with its own unique characteristics and benefits:

-

Rigid LED PCBs: These are the most common type of LED PCBs, made from a solid, non-flexible substrate material such as FR-4. Rigid LED PCBs offer excellent stability and durability, making them suitable for a wide range of applications.

-

Flexible LED PCBs: Flexible LED PCBs are made from a thin, flexible substrate material, such as polyimide or polyester. These boards can bend and conform to various shapes, making them ideal for applications with limited space or curved surfaces.

-

Metal Core LED PCBs: Metal Core PCBs (MCPCBs) feature a metal substrate, typically aluminum, which provides excellent thermal conductivity. This allows for efficient heat dissipation, making MCPCBs suitable for high-power LED applications.

-

Ceramic LED PCBs: Ceramic LED PCBs use a ceramic substrate, such as aluminum oxide or aluminum nitride, which offers superior thermal conductivity and electrical insulation properties. These boards are ideal for high-temperature and high-voltage LED applications.

Advantages of LED PCBs

LED PCBs offer several advantages over traditional LED mounting methods:

-

Compact design: LED PCBs allow for the integration of multiple LEDs in a small footprint, enabling the creation of compact and space-efficient lighting solutions.

-

Efficient heat dissipation: LED PCBs, especially Metal Core PCBs, provide excellent thermal management, ensuring that the LEDs operate at optimal temperatures and maintain their long lifespan.

-

Customization: LED PCBs can be customized to meet specific application requirements, such as LED arrangement, color, and brightness.

-

Reliability: LED PCBs offer a stable and reliable platform for LEDs, minimizing the risk of electrical and mechanical failures.

-

Cost-effective: Mass production of LED PCBs is cost-effective, making them an economical choice for large-scale LED lighting projects.

Designing LED PCBs

Designing LED PCBs involves several key considerations to ensure optimal performance, reliability, and longevity of the LEDs.

Factors to Consider When Designing LED PCBs

-

LED selection: Choose the appropriate type, size, and color of LEDs based on the application requirements, such as brightness, beam angle, and color temperature.

-

PCB material: Select the PCB substrate material based on the thermal, electrical, and mechanical requirements of the application. Common materials include FR-4, aluminum (for MCPCBs), and ceramics.

-

Circuit design: Design the electrical circuit to provide the correct voltage and current to the LEDs, ensuring proper operation and preventing damage. Consider using current-limiting resistors or constant current drivers.

-

Thermal management: Incorporate thermal management techniques, such as using thermal vias, heat sinks, or Metal Core PCBs, to efficiently dissipate heat generated by the LEDs.

-

Layout and placement: Optimize the layout and placement of LEDs on the PCB to achieve the desired illumination pattern and minimize shadowing effects.

-

Connector selection: Choose appropriate connectors for power input and output, considering factors such as current rating, voltage, and mechanical stability.

LED PCB Design Software

Several PCB design software packages are available for designing LED PCBs, such as:

- Altium Designer

- KiCad

- Eagle

- OrCAD

- Mentor Graphics PADS

These software tools provide features for schematic capture, PCB layout, and 3D modeling, enabling designers to create efficient and optimized LED PCB designs.

Manufacturing LED PCBs

The manufacturing process for LED PCBs involves several key steps to ensure the quality and reliability of the final product.

LED PCB Manufacturing Process

-

PCB fabrication: The PCB substrate is manufactured using standard PCB fabrication techniques, such as etching, drilling, and plating.

-

Solder mask application: A solder mask is applied to the PCB to protect the copper traces and prevent short circuits.

-

Silkscreen printing: A silkscreen layer is printed on the PCB to provide component labels, logos, and other markings.

-

LED mounting: LEDs are mounted on the PCB using various techniques, such as through-hole mounting, Surface-mount technology (SMT), or chip-on-board (COB) technology.

-

Soldering: The LEDs are soldered to the PCB using reflow soldering or wave soldering techniques, depending on the LED package and PCB design.

-

Quality control: The manufactured LED PCBs undergo rigorous quality control tests, including visual inspection, electrical testing, and thermal imaging, to ensure proper functionality and reliability.

LED PCB Assembly Techniques

Various LED PCB assembly techniques are used depending on the LED package and PCB design:

-

Through-hole mounting: LEDs with long leads are inserted into holes drilled in the PCB and soldered in place. This technique is suitable for low-density LED layouts and applications requiring high mechanical stability.

-

Surface-mount technology (SMT): Surface-mount LEDs are placed on the surface of the PCB and soldered using reflow soldering techniques. SMT allows for higher-density LED layouts and automated assembly processes.

-

Chip-on-board (COB) technology: COB involves mounting bare LED chips directly on the PCB and encapsulating them with a phosphor coating and lens. This technique enables the creation of compact, high-density LED arrays.

Applications of LED PCBs

LED PCBs find applications in a wide range of industries and products, including:

-

Automotive lighting: LED PCBs are used in automotive headlights, taillights, interior lighting, and instrument panel illumination.

-

General lighting: LED PCBs are employed in various general lighting applications, such as bulbs, tubes, panels, and downlights, offering energy-efficient and long-lasting lighting solutions.

-

Backlighting: LED PCBs are used for backlighting LCD displays in televisions, computer monitors, and mobile devices, providing uniform and high-quality illumination.

-

Signage and advertising: LED PCBs are used in illuminated signs, billboards, and other advertising displays, offering bright, eye-catching visuals.

-

Medical devices: LED PCBs are used in medical instruments, such as endoscopes, microscopes, and surgical lights, providing precise and reliable illumination.

-

Industrial and machine vision: LED PCBs are employed in industrial lighting and machine vision systems, offering high-intensity, uniform illumination for inspection and quality control processes.

-

Horticulture lighting: LED PCBs are used in grow lights for indoor and greenhouse horticulture, providing the optimal light spectrum and intensity for plant growth.

Frequently Asked Questions (FAQ)

-

What is the difference between rigid and flexible LED PCBs?

Rigid LED PCBs are made from a solid, non-flexible substrate material, offering excellent stability and durability. Flexible LED PCBs, on the other hand, are made from a thin, flexible substrate material, allowing them to bend and conform to various shapes. -

What are the advantages of using Metal Core PCBs for LED applications?

Metal Core PCBs (MCPCBs) offer excellent thermal conductivity, allowing for efficient heat dissipation from the LEDs. This helps to maintain optimal LED performance, reliability, and longevity, especially in high-power LED applications. -

How do I choose the appropriate LED for my PCB design?

When selecting LEDs for your PCB design, consider factors such as the required brightness, beam angle, color temperature, and LED package type. Evaluate the electrical, thermal, and mechanical requirements of your application to ensure compatibility with the chosen LED. -

What is the purpose of a current-limiting resistor in an LED circuit?

A current-limiting resistor is used in series with an LED to limit the current flowing through the LED. This is necessary because LEDs have a low forward voltage drop and can draw excessive current if directly connected to a voltage source, potentially causing damage to the LED. -

Can LED PCBs be customized for specific applications?

Yes, LED PCBs can be customized to meet specific application requirements. This includes customizing the LED arrangement, color, brightness, PCB shape, and size. Designers can work with PCB manufacturers to create custom LED PCB solutions tailored to their unique needs.

Conclusion

LED PCBs have transformed the way we design and integrate LED lighting solutions into various applications. By providing a compact, efficient, and versatile platform for LEDs, LED PCBs enable the creation of innovative and high-performance lighting products. Understanding the basics of LED PCBs, their design considerations, manufacturing processes, and practical applications is crucial for professionals working in the electronics and lighting industries.

As technology advances and new materials and techniques emerge, the capabilities of LED PCBs will continue to expand, opening up new possibilities for energy-efficient, long-lasting, and visually appealing lighting solutions. By staying informed about the latest developments in LED PCB technology, designers and engineers can create cutting-edge products that meet the ever-growing demands of the market.

No responses yet