Introduction to PCB Advancements

Printed Circuit Boards (PCBs) have been the backbone of electronic devices for decades. As technology continues to evolve, so do PCBs. In this article, we will explore the latest advancements in PCB technologies and what the future holds for these essential components.

The Evolution of PCB Technologies

PCBs have come a long way since their inception in the 1930s. The first PCBs were simple, single-sided boards with through-hole components. Over time, PCBs have become more complex, with multiple layers, surface-mount components, and high-density interconnects.

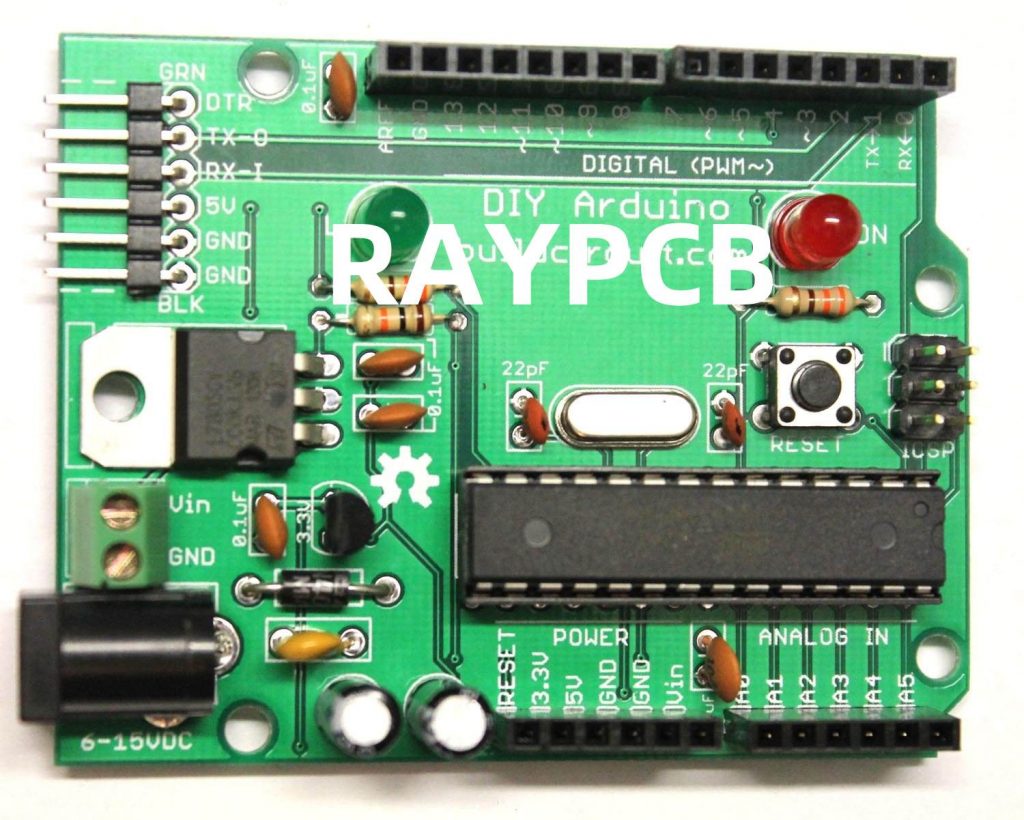

Single-Sided PCBs

Single-sided PCBs have copper traces on one side of the board and components on the other. They are the simplest and most cost-effective type of PCB.

Double-Sided PCBs

Double-sided PCBs have copper traces on both sides of the board, allowing for more complex circuits and higher component density.

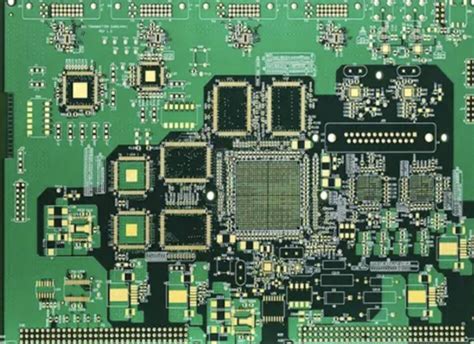

Multi-Layer PCBs

Multi-layer PCBs have multiple layers of copper traces separated by insulating material. They allow for even higher component density and more complex circuits.

| PCB Type | Layers | Complexity | Cost |

|---|---|---|---|

| Single-Sided | 1 | Low | Low |

| Double-Sided | 2 | Medium | Medium |

| Multi-Layer | 3+ | High | High |

Recent Advancements in PCB Technologies

High-Density Interconnect (HDI) PCBs

HDI PCBs use micro-vias and fine-pitch traces to achieve even higher component density. They are commonly used in smartphones, wearables, and other small electronic devices.

Flexible PCBs

Flexible PCBs use flexible substrates, such as polyimide, to create bendable and stretchable circuits. They are ideal for wearable devices, medical implants, and other applications where flexibility is required.

Rigid-Flex PCBs

Rigid-flex PCBs combine the benefits of rigid and flexible PCBs. They have rigid sections for mounting components and flexible sections for connecting them. This allows for more compact and reliable designs.

3D PCBs

3D PCBs use multiple layers of flexible and rigid PCBs to create three-dimensional circuits. They offer even greater design flexibility and allow for more compact devices.

The Future of PCB Technologies

As electronic devices continue to become smaller, faster, and more complex, PCB technologies will need to keep pace. Here are some of the trends we can expect to see in the future:

Increased Use of Embedded Components

Embedding components, such as resistors and capacitors, directly into the PCB substrate can save space and improve performance. This trend is likely to continue as devices become smaller and more complex.

More Advanced Materials

New materials, such as graphene and carbon nanotubes, offer the potential for even higher performance and smaller form factors. As these materials become more accessible, we can expect to see them used in PCBs.

Greater Integration with Other Technologies

PCBs will need to integrate with other technologies, such as sensors, antennas, and power management systems, to create more capable and efficient devices.

Sustainability and Recyclability

As environmental concerns grow, there will be a greater focus on creating PCBs that are sustainable and recyclable. This may involve using new materials and manufacturing processes that minimize waste and energy consumption.

Frequently Asked Questions (FAQ)

What is a PCB?

A PCB, or Printed Circuit Board, is a board made of insulating material with conductive traces, pads, and other features etched onto its surface. It is used to mechanically support and electrically connect electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate.

What are the different types of PCBs?

There are several types of PCBs, including:

- Single-sided PCBs

- Double-sided PCBs

- Multi-layer PCBs

- Flexible PCBs

- Rigid-flex PCBs

- High-Density Interconnect (HDI) PCBs

What are the benefits of using HDI PCBs?

HDI PCBs offer several benefits, including:

- Higher component density

- Smaller form factors

- Improved signal integrity

- Reduced power consumption

- Lower costs for complex designs

What are the challenges of using flexible PCBs?

Flexible PCBs present some unique challenges, including:

- Limited component options due to the flexible substrate

- Difficulty in handling and assembly

- Increased costs compared to rigid PCBs

- Reduced thermal dissipation compared to rigid PCBs

What is the future of PCB technologies?

The future of PCB technologies is likely to involve:

- Increased use of embedded components

- More advanced materials, such as graphene and carbon nanotubes

- Greater integration with other technologies, such as sensors and antennas

- A focus on sustainability and recyclability

Conclusion

PCB technologies have come a long way since their inception and continue to evolve to meet the demands of modern electronic devices. From HDI and flexible PCBs to 3D and embedded components, there are many exciting advancements happening in the world of PCBs. As we look to the future, we can expect to see even more innovation and integration with other technologies, as well as a greater focus on sustainability and recyclability. With these advancements, PCBs will continue to play a critical role in the development of new and innovative electronic devices.

No responses yet