The Rise of PCB Manufacturing in Vietnam

Over the past decade, Vietnam has witnessed a significant growth in its electronics manufacturing sector, with PCB production playing a crucial role in this development. Several factors have contributed to the rise of PCB manufacturing in Vietnam:

1. Cost-Competitive Labor

One of the primary reasons for Vietnam’s attractiveness as a PCB manufacturing destination is its cost-competitive labor force. Compared to other countries in the region, such as China and South Korea, Vietnam offers significantly lower labor costs, making it an appealing option for electronics companies looking to reduce their production expenses.

2. Government Support and Incentives

The Vietnamese government has played a proactive role in promoting the growth of the electronics manufacturing industry, including PCB production. The government has implemented various policies and incentives to attract foreign investment, such as tax breaks, land lease exemptions, and streamlined administrative procedures. These measures have created a favorable business environment for PCB manufacturers to establish and expand their operations in Vietnam.

3. Improving Infrastructure

Vietnam has made substantial investments in developing its infrastructure to support the growth of its manufacturing sector. The country has been improving its transportation networks, including roads, ports, and airports, to facilitate the efficient movement of goods and materials. Additionally, Vietnam has been expanding its power generation capacity and enhancing its telecommunications infrastructure to meet the increasing demands of the electronics industry.

4. Skilled Workforce

Vietnam has a young and educated workforce, with a growing number of engineers and technicians specializing in electronics manufacturing. The country’s universities and vocational training institutions have been collaborating with industry partners to develop curricula that align with the needs of the PCB manufacturing sector. This has resulted in a pool of skilled workers capable of meeting the technical requirements of PCB production.

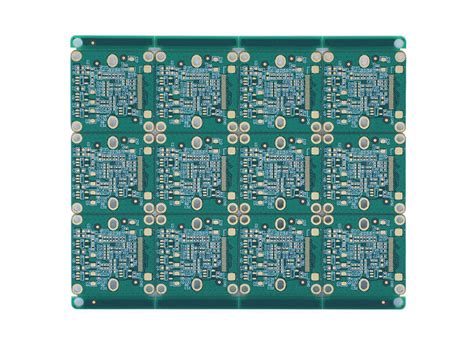

PCB Manufacturing Capabilities in Vietnam

Vietnam’s PCB manufacturing industry has been expanding its capabilities to cater to the diverse needs of international electronics companies. The country’s PCB manufacturers offer a wide range of services, including:

1. Multilayer PCBs

Vietnamese PCB manufacturers have the capability to produce multilayer PCBs, which are essential for complex electronic devices such as smartphones, tablets, and automotive electronics. These PCBs can have up to 20 layers or more, allowing for higher component density and improved performance.

2. High-Density Interconnect (HDI) PCBs

HDI PCBs are characterized by their fine line widths, small via sizes, and high connection pad density. Vietnamese PCB manufacturers have invested in advanced equipment and processes to produce HDI PCBs, which are commonly used in compact electronic devices such as wearables and Internet of Things (IoT) applications.

3. Flexible and Rigid-Flex PCBs

Flexible and Rigid-Flex PCBs are gaining popularity due to their ability to conform to the shape of the device and withstand repeated flexing. Vietnamese PCB manufacturers have the expertise to produce these types of PCBs, which are used in applications such as medical devices, aerospace electronics, and consumer electronics.

4. Quick-Turn Prototyping

Many Vietnamese PCB manufacturers offer quick-turn prototyping services to support the product development efforts of their clients. These services allow electronics companies to rapidly iterate on their designs and bring their products to market faster.

Quality and Standards in PCB Vietnam

Vietnamese PCB manufacturers have been focusing on improving their quality management systems and adhering to international standards to meet the stringent requirements of global electronics companies. Many PCB manufacturers in Vietnam have obtained certifications such as:

1. ISO 9001 Quality Management System

ISO 9001 is an international standard that specifies requirements for a quality management system. It helps organizations ensure that their products and services consistently meet customer requirements and regulatory standards. Many Vietnamese PCB manufacturers have achieved ISO 9001 certification, demonstrating their commitment to quality and continuous improvement.

2. UL Certification

Underwriters Laboratories (UL) is a global safety certification company that tests and certifies products to ensure they meet safety standards. Vietnamese PCB manufacturers that have obtained UL certification have demonstrated their ability to produce PCBs that comply with UL’s safety requirements, which are recognized by many international electronics companies.

3. RoHS Compliance

The Restriction of Hazardous Substances (RoHS) directive is a European Union regulation that restricts the use of certain hazardous substances in electrical and electronic equipment. Vietnamese PCB manufacturers have been adopting RoHS-compliant materials and processes to meet the requirements of their customers and demonstrate their commitment to environmental sustainability.

Challenges and Opportunities for PCB Vietnam

While Vietnam’s PCB manufacturing industry has made significant strides in recent years, it also faces certain challenges that need to be addressed to maintain its competitive edge:

1. Supply Chain Development

Vietnam’s PCB manufacturing industry still relies on imported raw materials and components, which can lead to longer lead times and higher costs. Developing a robust local supply chain for PCB materials and components would help Vietnamese manufacturers reduce their dependence on imports and improve their cost-competitiveness.

2. Skill Development

As the PCB manufacturing industry in Vietnam continues to grow, there is an increasing demand for skilled workers, particularly in areas such as design, process engineering, and quality control. Collaborating with educational institutions and investing in training programs will be crucial to ensure a steady supply of qualified personnel to support the industry’s growth.

3. Intellectual Property Protection

Protecting intellectual property rights is a critical concern for international electronics companies operating in Vietnam. Strengthening the country’s intellectual property laws and enforcement mechanisms would help build trust and confidence among foreign investors, encouraging them to establish long-term partnerships with Vietnamese PCB manufacturers.

Despite these challenges, the PCB manufacturing industry in Vietnam also presents significant opportunities for growth and development:

1. Diversification of End-Markets

While Vietnam’s PCB manufacturing industry has been primarily focused on serving the consumer electronics sector, there is potential to diversify into other end-markets such as automotive, medical, and aerospace electronics. These sectors have unique requirements and offer high growth potential, presenting opportunities for Vietnamese PCB manufacturers to expand their customer base and increase their value proposition.

2. Industry 4.0 Technologies

Adopting Industry 4.0 technologies such as automation, artificial intelligence, and the Internet of Things (IoT) can help Vietnamese PCB manufacturers improve their operational efficiency, product quality, and flexibility. Investing in these technologies will be crucial to staying competitive in an increasingly digital and connected world.

3. Regional Integration

Vietnam’s strategic location in Southeast Asia and its participation in regional trade agreements such as the Regional Comprehensive Economic Partnership (RCEP) and the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) provide opportunities for Vietnamese PCB manufacturers to access new markets and integrate into regional supply chains.

Frequently Asked Questions (FAQ)

1. What are the advantages of manufacturing PCBs in Vietnam?

Vietnam offers several advantages for PCB manufacturing, including cost-competitive labor, government support and incentives, improving infrastructure, and a skilled workforce. These factors have made Vietnam an attractive destination for international electronics companies looking to establish their production facilities.

2. What types of PCBs can be manufactured in Vietnam?

Vietnamese PCB manufacturers have the capability to produce a wide range of PCBs, including multilayer PCBs, high-density interconnect (HDI) PCBs, flexible and rigid-flex PCBs, and quick-turn prototyping services. They can cater to the diverse needs of international electronics companies across various industries.

3. How do Vietnamese PCB manufacturers ensure quality and compliance with international standards?

Many Vietnamese PCB manufacturers have obtained certifications such as ISO 9001 for quality management, UL certification for safety, and RoHS compliance for environmental sustainability. These certifications demonstrate their commitment to meeting the stringent requirements of global electronics companies and adhering to international standards.

4. What challenges does Vietnam’s PCB manufacturing industry face?

Vietnam’s PCB manufacturing industry faces challenges such as the need for supply chain development to reduce dependence on imported raw materials, skill development to meet the growing demand for qualified personnel, and the need for stronger intellectual property protection to attract foreign investment.

5. What opportunities exist for growth and development in Vietnam’s PCB manufacturing industry?

Opportunities for growth and development in Vietnam’s PCB manufacturing industry include diversification into new end-markets such as automotive, medical, and aerospace electronics, adoption of Industry 4.0 technologies to improve operational efficiency and product quality, and regional integration through participation in trade agreements to access new markets and supply chains.

Conclusion

Vietnam has emerged as a significant player in the global PCB manufacturing landscape, thanks to its cost-competitive labor, government support, improving infrastructure, and skilled workforce. The country’s PCB manufacturers offer a wide range of capabilities, from multilayer PCBs to HDI and flexible PCBs, catering to the diverse needs of international electronics companies.

While Vietnam’s PCB manufacturing industry faces challenges such as supply chain development, skill development, and intellectual property protection, it also presents significant opportunities for growth and development. By diversifying into new end-markets, adopting Industry 4.0 technologies, and leveraging regional integration, Vietnamese PCB manufacturers can strengthen their competitive position and contribute to the country’s economic growth.

As the global electronics industry continues to evolve, Vietnam’s PCB manufacturing sector is well-positioned to play a key role in shaping its future. With the right strategies and investments, Vietnam can solidify its position as a leading PCB manufacturing hub, attracting more international electronics companies and driving innovation in the industry.

| Category | Description |

|---|---|

| Advantages | – Cost-competitive labor – Government support and incentives – Improving infrastructure – Skilled workforce |

| Capabilities | – Multilayer PCBs – High-Density Interconnect (HDI) PCBs – Flexible and Rigid-Flex PCBs – Quick-Turn Prototyping |

| Quality and Standards | – ISO 9001 Quality Management System – UL Certification – RoHS Compliance |

| Challenges | – Supply chain development – Skill development – Intellectual property protection |

| Opportunities | – Diversification of end-markets – Adoption of Industry 4.0 technologies – Regional integration |

No responses yet