Factors Affecting PCB Size

Several key factors come into play when calculating the size of a PCB:

1. Component Footprint

The footprint of each component on the PCB is a critical factor in determining the overall board size. The footprint includes the physical dimensions of the component and the required spacing around it for proper soldering and assembly. Larger components, such as transformers, connectors, and heat sinks, will naturally require more space on the PCB.

2. Routing and Trace Width

The routing of traces between components also affects the PCB size. Trace width is determined by the current carrying capacity and the manufacturing capabilities of the PCB fabricator. Higher current traces require wider widths, which can increase the overall board size. Additionally, the spacing between traces must be considered to avoid signal interference and maintain manufacturability.

3. Layer Count

The number of layers in a PCB directly influences its size. Multi-layer boards allow for more efficient routing and component placement, as traces can be routed on internal layers. This can result in a smaller overall board size compared to a single-layer board with the same functionality. However, adding layers also increases the complexity and cost of the PCB.

4. Manufacturing Constraints

PCB manufacturers have specific capabilities and constraints that impact the minimum and maximum board sizes they can produce. These constraints include:

- Minimum trace width and spacing

- Minimum drill size

- Minimum annular ring

- Maximum board dimensions

It is essential to consult with your PCB manufacturer to understand their specific constraints and ensure your design falls within their capabilities.

Calculating PCB Size

Now that we have discussed the factors affecting PCB size let’s walk through the steps to calculate the dimensions of your board.

Step 1: Determine Component Placement

Begin by placing all the necessary components on the PCB layout. Consider the following guidelines:

- Group related components together to minimize trace lengths and improve signal integrity

- Place larger components first, as they have the most significant impact on board size

- Ensure proper spacing between components for soldering and assembly

- Consider Component orientation for optimal routing and space utilization

Step 2: Estimate Board Dimensions

Based on the component placement, estimate the minimum board dimensions required to accommodate all components and their necessary spacing. This initial estimate will give you a starting point for further refinement.

Step 3: Define Trace Widths and Spacing

Determine the appropriate trace widths for your design based on the current requirements and the PCB manufacturer’s capabilities. The following table provides a general guideline for trace widths based on current capacity:

| Current (A) | Trace Width (mm) |

|---|---|

| 0.5 | 0.15 |

| 1.0 | 0.3 |

| 2.0 | 0.6 |

| 3.0 | 0.9 |

| 4.0 | 1.2 |

Also, consider the minimum spacing between traces to maintain signal integrity and manufacturability. Consult with your PCB manufacturer for their specific requirements.

Step 4: Route the Board

Using the estimated board dimensions and defined trace widths and spacing, route the PCB layout. Optimize the routing to minimize board size while maintaining signal integrity and manufacturability. Consider the following techniques:

- Use the smallest trace width and spacing possible for your design

- Route traces on multiple layers to reduce board size

- Utilize via-in-pad technology to minimize component spacing

- Employ diagonal routing to reduce trace lengths and board size

Step 5: Refine Board Dimensions

After routing the board, adjust the board dimensions as necessary to accommodate any changes in component placement or routing. Ensure that the final board size meets the minimum and maximum dimensions specified by your PCB manufacturer.

Step 6: Add Mounting Holes and Edge Clearance

Include mounting holes and edge clearance in your PCB design. Mounting holes are necessary for securing the PCB to an enclosure or chassis. Edge clearance provides space for the PCB to be safely handled and assembled. The following table provides recommended minimum edge clearance based on board thickness:

| Board Thickness (mm) | Minimum Edge Clearance (mm) |

|---|---|

| 0.8 – 1.6 | 1.5 |

| 1.6 – 2.4 | 2.0 |

| 2.4 – 3.2 | 2.5 |

| 3.2 – 4.0 | 3.0 |

Step 7: Review and Finalize Design

Before finalizing your PCB design, review the layout to ensure that all components fit within the board dimensions and that the routing meets the necessary electrical and manufacturing requirements. Make any final adjustments to optimize the design and minimize the board size.

PCB Size Optimization Techniques

In addition to the steps outlined above, there are several techniques you can employ to optimize the size of your PCB:

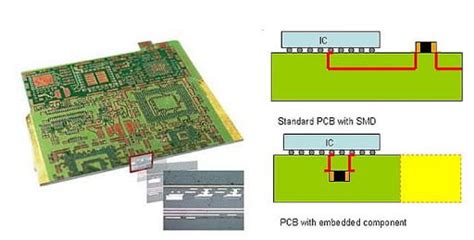

1. Use Surface Mount Devices (SMDs)

SMDs have smaller footprints compared to through-hole components, allowing for more compact PCB designs. Whenever possible, opt for SMD components to minimize board size.

2. Employ High-Density Interconnect (HDI) Technology

HDI PCBs utilize smaller vias, finer trace widths, and higher layer counts to achieve greater routing density and smaller board sizes. Consider using HDI technology for complex designs with limited space.

3. Optimize Component Orientation

Carefully consider the orientation of components on the PCB. Rotating components can sometimes allow for more efficient routing and smaller board sizes.

4. Use Blind and Buried Vias

Blind and buried vias connect inner layers of the PCB without being visible on the outer layers. This technique can help reduce board size by allowing for more efficient routing and component placement.

5. Consider Flexible PCBs

For applications with limited space or unique form factors, consider using flexible PCBs. Flexible PCBs can be bent and folded to fit into tight spaces, reducing the overall footprint of the device.

FAQ

1. What is the minimum PCB size that can be manufactured?

The minimum PCB size depends on the capabilities of the specific manufacturer. Typically, the smallest PCB size that can be reliably manufactured is around 0.4″ x 0.4″ (10mm x 10mm). However, some specialized manufacturers may be able to produce smaller sizes.

2. How do I determine the appropriate trace width for my PCB design?

Trace width is determined by the current carrying capacity required for each signal. Refer to the table provided in the “Step 3: Define Trace Widths and Spacing” section of this article for a general guideline. Additionally, consult with your PCB manufacturer for their specific requirements and capabilities.

3. Can I reduce PCB size by using smaller components?

Yes, using smaller components, such as SMDs, can significantly reduce the overall PCB size. When selecting components for your design, consider their footprint and choose the smallest options that meet your performance requirements.

4. How does the number of layers affect PCB size?

Increasing the number of layers in a PCB allows for more efficient routing and component placement, as traces can be routed on internal layers. This can result in a smaller overall board size compared to a single-layer board with the same functionality. However, adding layers also increases the complexity and cost of the PCB.

5. What should I do if my PCB design exceeds the maximum size capabilities of my manufacturer?

If your PCB design exceeds the maximum size capabilities of your chosen manufacturer, you have a few options:

- Optimize your design using the techniques outlined in this article to reduce the board size.

- Consider breaking your design into multiple smaller PCBs that can be interconnected.

- Consult with your manufacturer to see if they can accommodate your design through special arrangements or by outsourcing to a partner with larger size capabilities.

- Look for an alternative PCB manufacturer that can handle larger board sizes.

Conclusion

Calculating the size of a PCB involves considering various factors, including component footprint, routing and trace width, layer count, and manufacturing constraints. By following the steps outlined in this article and employing PCB size optimization techniques, you can determine the optimal dimensions for your PCB project.

Remember to consult with your PCB manufacturer to ensure your design falls within their capabilities and to address any specific requirements or constraints they may have. With careful planning and attention to detail, you can create a compact, functional, and manufacturable PCB that meets your project’s needs.

No responses yet