What are Prototype Boards?

Prototype boards, also known as breadboards or development boards, are essential tools for electronics enthusiasts, hobbyists, and professionals alike. These boards provide a platform for quickly and easily building and testing electronic circuits without the need for soldering. Prototype boards allow users to create temporary circuits by inserting components and wires into the board’s holes, which are connected by conductive strips underneath the surface.

Types of Prototype Boards

There are several types of prototype boards available, each with its own unique features and benefits:

- Solderless Breadboards: These are the most common type of prototype boards. They feature a grid of holes connected by conductive strips, allowing users to quickly insert and remove components and wires.

- Stripboards: Also known as veroboards, these boards have a grid of holes with copper strips running parallel to each other. Users can cut the strips to create custom connections between components.

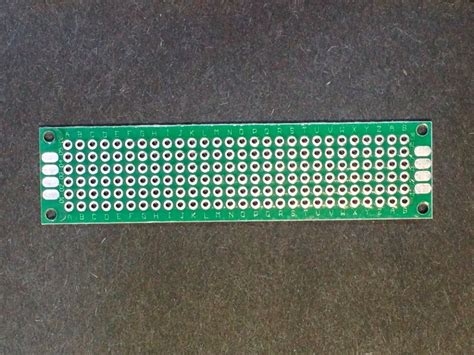

- PCB Prototype Boards: These boards are designed to mimic the layout of a printed circuit board (PCB). They often have pre-defined pad layouts for common components, such as integrated circuits (ICs) and surface-mount devices (SMDs).

- Modular Prototype Boards: These boards consist of multiple smaller boards that can be connected together to create larger, more complex circuits. They often have standardized connectors, such as pin headers or edge connectors, for easy integration.

| Type | Advantages | Disadvantages |

|---|---|---|

| Solderless Breadboard | Quick and easy to use, no soldering required | Limited to low-frequency circuits, connections can be unreliable |

| Stripboard | Allows for custom connections, can be used for permanent circuits | Requires cutting strips, more time-consuming than breadboards |

| PCB Prototype Board | Mimics the layout of a PCB, suitable for SMD components | Limited flexibility compared to breadboards and stripboards |

| Modular Prototype Board | Allows for larger, more complex circuits, easy to integrate modules | Can be more expensive than other options, requires more planning |

Advantages of Using Prototype Boards

Rapid Prototyping

One of the main advantages of using prototype boards is the ability to quickly build and test electronic circuits. With solderless breadboards, components can be easily inserted and removed, allowing users to experiment with different configurations and make changes on the fly. This rapid prototyping capability is particularly useful in the early stages of circuit design, where multiple iterations may be necessary to achieve the desired functionality.

Cost-Effective

Prototype boards are also cost-effective compared to other methods of building electronic circuits. Instead of creating a custom PCB for each iteration of a design, prototype boards allow users to reuse components and make changes without incurring additional costs. This is especially beneficial for hobbyists and small businesses with limited budgets.

Educational Value

Prototype boards are valuable educational tools for those learning about electronics. By providing a hands-on way to build and test circuits, prototype boards help students and enthusiasts gain a deeper understanding of electronic components, circuit design, and troubleshooting techniques. Many educational institutions and online learning platforms incorporate prototype boards into their electronics curricula.

Choosing the Right Prototype Board

When selecting a prototype board for your project, consider the following factors:

- Size: Choose a board that is large enough to accommodate your circuit, but not so large that it becomes unwieldy. Consider the number of components you’ll be using and the complexity of your design.

- Connectivity: Look for a board with the right type of connections for your components. Solderless breadboards are suitable for through-hole components, while PCB prototype boards may be better for SMD components.

- Quality: Invest in a high-quality prototype board from a reputable manufacturer. Cheaper boards may have lower-quality contacts or inconsistent connections, which can lead to frustrating debugging sessions.

- Compatibility: Ensure that the prototype board you choose is compatible with the other tools and components you’ll be using, such as power supplies, microcontrollers, and sensors.

Tips for Using Prototype Boards

To get the most out of your prototype board, follow these tips:

- Plan your layout: Before starting to build your circuit, take some time to plan the layout of your components on the board. This will help you avoid errors and make your circuit easier to understand and debug.

- Use color-coded wires: Using different colors for power, ground, and signal wires can make your circuit more organized and easier to follow.

- Keep wires short: Long wires can introduce unwanted noise and resistance into your circuit. Try to keep your connections as short as possible.

- Use a multimeter: A multimeter is an essential tool for debugging and testing your circuit. Use it to check for continuity, measure voltages, and identify short circuits.

- Document your work: As you build your circuit, keep a record of your layout, component values, and any changes you make. This will make it easier to recreate your design later or troubleshoot issues.

Common Applications of Prototype Boards

Prototype boards are used in a wide range of applications, from hobby projects to professional product development. Some common applications include:

- Arduino and Raspberry Pi Projects: Prototype boards are often used in conjunction with popular microcontroller and single-board computer platforms like Arduino and Raspberry Pi. They provide a convenient way to connect sensors, actuators, and other peripherals to these devices.

- Internet of Things (IoT) devices: Many IoT devices, such as smart home sensors and wearable technology, are developed using prototype boards. The rapid prototyping capabilities of these boards allow designers to quickly iterate on their designs and test new features.

- Robotics: Prototype boards are commonly used in robotics projects to build control circuits, sensor interfaces, and motor drivers. The modular nature of some prototype boards makes them well-suited for building complex robotic systems.

- Audio and music applications: DIY audio enthusiasts often use prototype boards to build custom effects pedals, synthesizers, and other musical electronics. The ability to quickly swap out components and experiment with different circuit configurations is particularly valuable in this context.

Frequently Asked Questions (FAQ)

- What is the difference between a breadboard and a prototype board?

A breadboard is a specific type of prototype board that features a grid of holes connected by conductive strips. The term “prototype board” encompasses a broader range of boards, including stripboards, PCB prototype boards, and modular boards. - Can I use a prototype board for a permanent installation?

While prototype boards are primarily designed for temporary use, some types, such as stripboards, can be used for permanent installations. However, for long-term reliability and durability, it is generally recommended to transfer your circuit to a custom PCB once your design is finalized. - How do I connect a prototype board to a power supply?

Most prototype boards have dedicated power and ground rails that run alongside the main grid of holes. To connect a power supply, you can use jumper wires to connect the positive and negative terminals of your supply to the appropriate rails on the board. Always double-check your connections and ensure that your power supply is set to the correct voltage for your circuit. - What should I do if my circuit isn’t working on the prototype board?

If your circuit isn’t functioning as expected, start by visually inspecting your connections and component placements. Use a multimeter to check for continuity and ensure that there are no short circuits. If the issue persists, try removing and reinserting components, or consult online forums or resources for troubleshooting advice specific to your circuit. - Can I use SMD components on a prototype board?

Some prototype boards, such as PCB prototype boards, are designed to accommodate SMD components. However, solderless breadboards and stripboards are generally more suitable for through-hole components. If you need to use SMD components with a breadboard or stripboard, you may need to use breakout boards or adapter modules to provide compatible connections.

Conclusion

Prototype boards are invaluable tools for anyone working with electronics, offering a quick, easy, and cost-effective way to build and test circuits. By understanding the different types of prototype boards available and how to use them effectively, you can streamline your design process and bring your electronic projects to life more efficiently. Whether you’re a beginner learning the basics of electronics or a seasoned professional developing cutting-edge technology, investing in a high-quality prototype board is a decision that will pay dividends in your work.

No responses yet