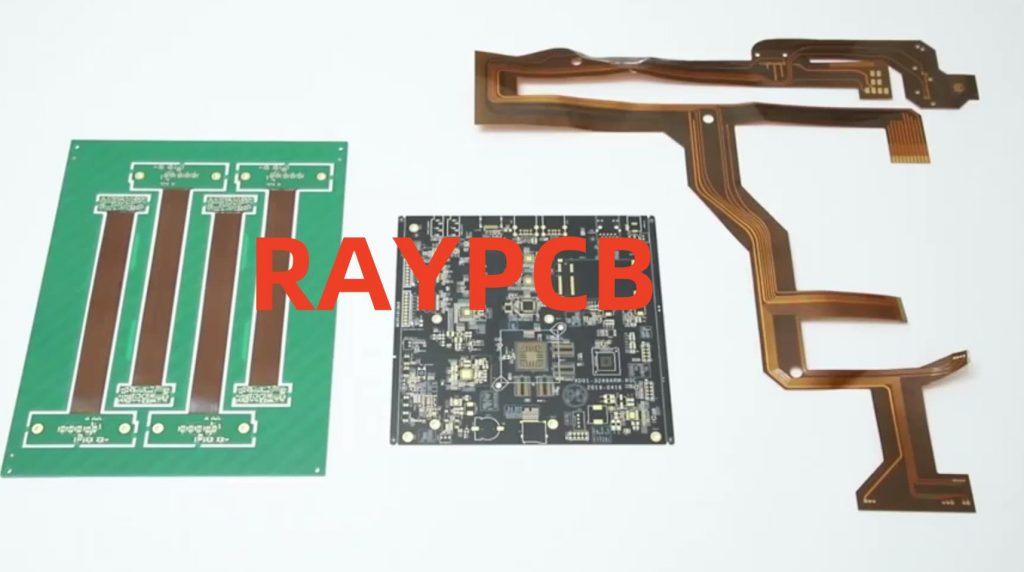

Introduction to Flexible PCB Prototypes

Flexible PCB (Printed Circuit Board) prototypes are essential components in the development of modern electronic devices. These innovative circuit boards offer unique advantages over traditional rigid PCBs, such as increased flexibility, lightweight construction, and improved durability. As a result, flexible PCB Prototypes have become increasingly popular in various industries, including consumer electronics, medical devices, automotive systems, and aerospace applications.

What are Flexible PCBs?

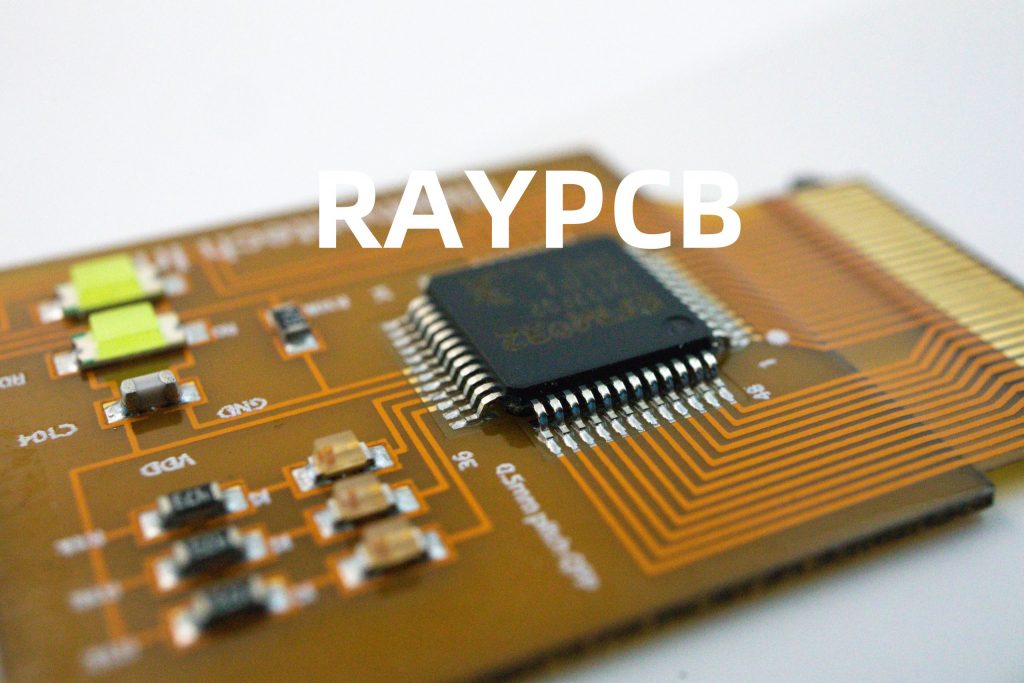

Flexible PCBs, also known as flex circuits, are thin, lightweight, and flexible circuit boards that can be bent, twisted, or folded without damaging the electrical connections. They consist of a flexible substrate, typically made of polyimide or other flexible materials, with conductive traces and components attached to it. This unique construction allows flexible PCBs to be used in applications where traditional rigid PCBs cannot be accommodated due to space constraints or the need for flexibility.

Advantages of Flexible PCB Prototypes

Flexible PCB prototypes offer several advantages over rigid PCBs, making them an attractive choice for many applications:

- Flexibility: The most obvious advantage of flexible PCBs is their ability to bend and flex without damaging the electrical connections. This allows for more compact and space-efficient designs in electronic devices.

- Lightweight: Flexible PCBs are typically thinner and lighter than rigid PCBs, making them ideal for portable and wearable devices where weight is a critical factor.

- Durability: The flexible nature of these PCBs allows them to withstand vibrations, shocks, and other mechanical stresses better than rigid PCBs, increasing the overall reliability of the electronic device.

- Improved Signal Integrity: Flexible PCBs can be designed with shorter signal paths and reduced electromagnetic interference (EMI), resulting in improved signal integrity and higher-speed performance.

- Cost-Effective: In some cases, using flexible PCBs can reduce the overall cost of an electronic device by eliminating the need for separate connectors and wiring harnesses.

Flexible PCB Prototype Manufacturing Process

The manufacturing process for flexible PCB prototypes involves several steps, each requiring specialized equipment and expertise.

Step 1: Design and Layout

The first step in creating a flexible PCB prototype is designing the circuit and laying out the components on the flexible substrate. This process involves using specialized PCB design software to create a digital representation of the circuit, including the placement of components, routing of traces, and any necessary cutouts or folds in the substrate.

Step 2: Substrate Preparation

Once the design is finalized, the flexible substrate is prepared for the subsequent manufacturing steps. This may involve cleaning the substrate, applying an adhesive layer, or laminating multiple layers of substrate material together to achieve the desired thickness and flexibility.

Step 3: Copper Foil Lamination

A thin layer of copper foil is then laminated onto the prepared substrate using heat and pressure. This copper layer will form the conductive traces and pads on the flexible PCB.

Step 4: Photoresist Application and Exposure

A photoresist material is applied to the copper-clad substrate and then exposed to UV light through a photomask containing the circuit pattern. This process selectively hardens the photoresist in the desired areas, protecting the copper underneath.

Step 5: Etching and Stripping

The exposed copper is then etched away using a chemical solution, leaving behind the desired circuit pattern. The remaining photoresist is then stripped away, revealing the completed copper traces and pads.

Step 6: Coverlay Application and Finishing

A protective coverlay is applied over the copper traces to insulate and protect them from damage. Additional finishing steps, such as surface treatment, solder mask application, or silkscreen printing, may also be performed depending on the specific requirements of the flexible PCB prototype.

Step 7: Cutting and Forming

Finally, the completed flexible PCB is cut to the desired shape and size using specialized cutting tools. If necessary, the PCB may also be formed or folded into the required configuration for the final application.

Flexible PCB Prototype Manufacturing Services

Several companies offer flexible PCB prototype manufacturing services, catering to the unique needs of various industries and applications.

Choosing a Flexible PCB Prototype Manufacturer

When selecting a flexible PCB prototype manufacturer, it is essential to consider several factors to ensure the best possible results:

- Experience and Expertise: Look for a manufacturer with extensive experience in producing flexible PCB prototypes for your specific industry or application. They should have a deep understanding of the unique challenges and requirements associated with flexible PCBs.

- Manufacturing Capabilities: Ensure that the manufacturer has the necessary equipment and facilities to produce high-quality flexible PCB prototypes. This includes specialized lamination equipment, photoresist exposure systems, and precise cutting and forming tools.

- Quality Control: A reputable flexible PCB prototype manufacturer should have stringent quality control measures in place to ensure that each prototype meets the required specifications and performance standards. This may include automated optical inspection (AOI), electrical testing, and other quality assurance procedures.

- Turnaround Time: Depending on your project timeline, you may need to consider the manufacturer’s turnaround time for producing flexible PCB prototypes. Some companies offer expedited services for faster delivery, while others may require longer lead times for more complex designs.

- Customer Support: Look for a manufacturer that provides excellent customer support throughout the entire manufacturing process. They should be responsive to your inquiries, provide regular updates on your project status, and be willing to work closely with you to address any issues or concerns that may arise.

Notable Flexible PCB Prototype Manufacturers

Several companies have established themselves as leaders in the flexible PCB prototype manufacturing industry. Some notable examples include:

- Epec Engineered Technologies: Epec offers a wide range of flexible PCB prototype services, including single and double-sided flex circuits, multi-layer flex circuits, and rigid-flex combinations. They have extensive experience in serving industries such as medical devices, aerospace, and military applications.

- Sierra Circuits: Sierra Circuits provides quick-turn flexible PCB prototype services, with lead times as short as 1-5 days for simple designs. They offer a variety of Flexible PCB Materials and can accommodate complex designs with multiple layers and thin traces.

- Advanced Circuits: Advanced Circuits offers flexible PCB prototype services with no minimum order quantities and fast turnaround times. They have experience in producing flex circuits for applications such as wearable devices, medical equipment, and automotive systems.

- Royal Circuits: Royal Circuits specializes in producing high-quality flexible PCB prototypes for a wide range of industries. They offer single and double-sided flex circuits, as well as rigid-flex combinations, with a focus on providing excellent customer support throughout the manufacturing process.

Applications of Flexible PCB Prototypes

Flexible PCB prototypes have found applications in various industries due to their unique properties and advantages over traditional rigid PCBs.

Consumer Electronics

Flexible PCBs are widely used in consumer electronics, such as smartphones, tablets, and wearable devices. They allow for more compact and lightweight designs, as well as improved durability and reliability. For example, a smartwatch may utilize a flexible PCB to accommodate the curved shape of the device while maintaining a thin profile and resistance to mechanical stress.

Medical Devices

The medical industry has increasingly adopted flexible PCBs for various applications, including implantable devices, diagnostic equipment, and patient monitoring systems. Flexible PCBs offer the advantage of conforming to the shape of the human body, reducing the size and weight of medical devices, and improving patient comfort. Additionally, the increased durability and reliability of flexible PCBs make them well-suited for use in life-critical medical applications.

Automotive Systems

Flexible PCBs are used in automotive systems for applications such as dashboard displays, climate control systems, and engine management modules. They offer the advantage of being able to fit into tight spaces and conform to the irregular shapes found in automotive interiors. Furthermore, the increased vibration and shock resistance of flexible PCBs makes them well-suited for use in the harsh environments encountered in automotive applications.

Aerospace and Military

Aerospace and military applications often require electronic devices that can withstand extreme temperatures, vibrations, and other harsh environmental conditions. Flexible PCBs offer a solution to these challenges, providing increased durability and reliability compared to rigid PCBs. They are used in applications such as avionics systems, satellite communication devices, and military wearables.

Future of Flexible PCB Prototype Manufacturing

As technology continues to advance and the demand for smaller, lighter, and more flexible electronic devices grows, the future of flexible PCB prototype manufacturing looks bright.

Advancements in Materials and Manufacturing Processes

Researchers and manufacturers are continuously developing new materials and manufacturing processes to improve the performance and capabilities of flexible PCBs. Some notable advancements include:

- Stretchable Electronics: Researchers are developing flexible PCBs that can not only bend but also stretch, opening up new possibilities for wearable devices and implantable medical applications.

- Transparent Conductors: The development of transparent conductive materials, such as indium tin oxide (ITO) and graphene, enables the creation of transparent flexible PCBs for use in displays and other optoelectronic devices.

- 3D Printing: Advancements in 3D printing technology are enabling the rapid prototyping of flexible PCBs with complex geometries and embedded components.

Challenges and Opportunities

While flexible PCB prototype manufacturing has made significant strides in recent years, there are still challenges and opportunities for further improvement:

- Cost Reduction: As with any emerging technology, the cost of producing flexible PCB prototypes can be higher than traditional rigid PCBs. Manufacturers are continually working to optimize their processes and reduce costs to make flexible PCBs more accessible to a wider range of applications.

- Design Complexity: Designing flexible PCBs can be more challenging than rigid PCBs due to the need to account for the mechanical properties of the flexible substrate and the potential for deformation during use. Continued development of specialized design software and simulation tools can help address these challenges.

- Standardization: As the flexible PCB industry grows, there is a need for standardization of materials, manufacturing processes, and testing methods to ensure consistent quality and reliability across different manufacturers.

Despite these challenges, the future of flexible PCB prototype manufacturing is promising, with new applications and opportunities emerging as technology continues to advance.

Frequently Asked Questions (FAQ)

- What is the typical turnaround time for flexible PCB prototypes?

The turnaround time for flexible PCB prototypes can vary depending on the complexity of the design and the manufacturer’s capabilities. Some companies offer expedited services with lead times as short as 1-5 days for simple designs, while more complex projects may require several weeks. - Can flexible PCBs be used in high-temperature environments?

Yes, some flexible PCBs are designed to withstand high temperatures. Polyimide, a common substrate material for flexible PCBs, has a high glass transition temperature and can maintain its properties at temperatures up to 300°C. However, it is essential to discuss your specific temperature requirements with your chosen manufacturer to ensure that the appropriate materials and manufacturing processes are used. - Are flexible PCBs more expensive than rigid PCBs?

In general, flexible PCBs tend to be more expensive than rigid PCBs due to the specialized materials and manufacturing processes involved. However, the cost difference can vary depending on the specific design requirements and the manufacturer’s pricing structure. In some cases, using a flexible PCB can result in overall cost savings for a project by reducing the need for separate connectors and wiring harnesses. - How do I choose the right flexible PCB prototype manufacturer for my project?

When selecting a flexible PCB prototype manufacturer, consider factors such as their experience and expertise in your specific industry or application, manufacturing capabilities, quality control measures, turnaround time, and customer support. Research potential manufacturers and request quotes and samples to compare their services and capabilities before making a decision. - Can flexible PCBs be used in medical implantable devices?

Yes, flexible PCBs are well-suited for use in medical implantable devices due to their ability to conform to the shape of the human body, reduced size and weight, and increased durability and reliability. However, implantable devices have stringent requirements for biocompatibility, sterilization, and long-term stability, so it is crucial to work with a manufacturer that has experience in producing flexible PCBs for medical applications and can ensure compliance with relevant regulations and standards.

Conclusion

Flexible PCB prototype manufacturing has revolutionized the electronics industry, enabling the development of smaller, lighter, and more durable devices across various sectors. From consumer electronics and medical devices to automotive systems and aerospace applications, flexible PCBs offer unique advantages over traditional rigid PCBs.

As technology continues to advance, the future of flexible PCB prototype manufacturing looks promising, with new materials, manufacturing processes, and applications emerging. While challenges such as cost reduction, design complexity, and standardization remain, manufacturers and researchers are continuously working to address these issues and push the boundaries of what is possible with flexible PCBs.

By partnering with experienced and reputable flexible PCB prototype manufacturers, companies can leverage the benefits of this innovative technology to create cutting-edge products that meet the evolving needs of their customers. As the demand for smaller, smarter, and more flexible electronic devices continues to grow, flexible PCB prototypes will undoubtedly play a crucial role in shaping the future of the electronics industry.

No responses yet