Introduction to PCB Prototypes

A printed circuit board (PCB) prototype is an essential step in the development of electronic devices. It allows designers and engineers to test and validate their designs before proceeding with mass production. PCB Prototypes enable the detection of potential issues, such as signal integrity problems, power distribution concerns, and component placement errors, early in the development process, saving time and money.

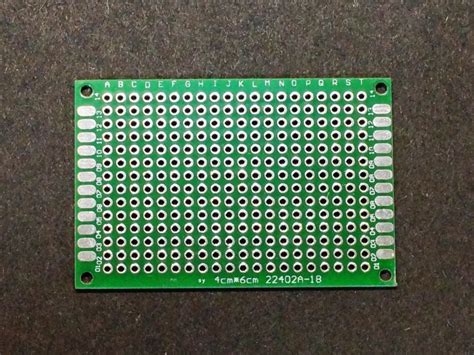

What is a PCB Prototype?

A PCB prototype is a physical representation of the designed circuit board, created to test and verify its functionality, performance, and compatibility with other components. It is a crucial step in the development process, as it allows engineers to identify and rectify any issues before committing to full-scale production.

Why are PCB Prototypes Important?

PCB prototypes play a vital role in the electronic design process for several reasons:

-

Design Validation: Prototypes allow designers to test and validate their circuit designs in a real-world environment, ensuring that the board functions as intended.

-

Error Detection: By creating a prototype, engineers can identify and correct any design flaws, component placement issues, or signal integrity problems before mass production.

-

Compatibility Testing: Prototypes enable designers to test the compatibility of the PCB with other components, such as sensors, connectors, and power supplies.

-

Cost Savings: Identifying and resolving issues during the prototyping phase can save significant costs associated with redesigning and reproducing boards later in the development process.

PCB Prototype Design Process

The PCB prototype design process involves several key steps, from conceptualization to the creation of the physical board.

Schematic Design

The first step in creating a PCB prototype is to develop a schematic diagram of the circuit. This diagram represents the electrical connections and components required for the desired functionality. Engineers use electronic design automation (EDA) tools to create the schematic, which serves as a blueprint for the PCB layout.

Component Selection

Once the schematic is complete, engineers select the appropriate components for the design. This process involves considering factors such as functionality, cost, availability, and compatibility with the overall system. Component selection is critical, as it directly impacts the performance and reliability of the final product.

PCB Layout Design

With the schematic and components in place, engineers proceed to design the PCB layout. This step involves arranging the components on the board and routing the electrical connections between them. The layout design must consider various factors, such as signal integrity, power distribution, thermal management, and manufacturing constraints.

Design Rule Check (DRC)

After completing the PCB layout, engineers perform a design rule check (DRC) to ensure that the design adheres to the specified manufacturing guidelines. The DRC verifies that the board meets the minimum clearance and width requirements, hole sizes, and other design rules specific to the chosen manufacturing process.

Gerber File Generation

Once the PCB layout passes the DRC, engineers generate Gerber files, which are industry-standard files used for PCB fabrication. Gerber files contain information about the board’s layers, traces, pads, and drills, enabling manufacturers to produce the physical PCB prototype.

PCB Prototype Fabrication Techniques

There are several methods for fabricating PCB prototypes, each with its advantages and limitations. The choice of fabrication technique depends on factors such as the complexity of the design, the required turnaround time, and the available budget.

Traditional PCB Fabrication

Traditional PCB fabrication involves the use of subtractive methods, such as etching and drilling, to create the circuit board. This process typically involves the following steps:

- Copper-clad laminate selection

- Dry film photoresist application

- Exposure and development of the photoresist

- Etching of the copper

- Photoresist removal

- Drilling of holes

- Solder mask application

- Silkscreen printing

Traditional PCB fabrication is suitable for producing high-quality prototypes and small to medium-sized production runs. However, it may be more time-consuming and expensive compared to other methods.

Rapid PCB Prototyping

Rapid PCB prototyping techniques have gained popularity in recent years due to their ability to produce prototypes quickly and cost-effectively. Some common rapid prototyping methods include:

-

3D Printing: 3D printing technology can be used to create PCB prototypes by depositing conductive and insulating materials layer by layer. This method is suitable for low-complexity designs and quick iterations.

-

Milling: PCB Milling involves using a computer-controlled milling machine to remove copper from a pre-clad board, creating the desired circuit pattern. This method is ideal for simple to medium-complexity designs and offers fast turnaround times.

-

Laser Etching: Laser etching uses a high-powered laser to remove the copper layer from a pre-clad board, creating the circuit pattern. This method is suitable for high-precision designs and offers quick turnaround times.

Rapid PCB prototyping techniques are generally faster and more cost-effective than traditional methods, making them ideal for early-stage design validation and iteration.

Outsourcing PCB Prototype Fabrication

Many companies choose to outsource their PCB prototype fabrication to specialized manufacturers. Outsourcing offers several advantages, such as access to advanced manufacturing capabilities, reduced capital investment, and faster turnaround times.

When outsourcing PCB prototype fabrication, it is essential to consider factors such as the manufacturer’s experience, quality control processes, and communication channels. Establishing a strong partnership with a reliable PCB prototype manufacturer can streamline the development process and ensure high-quality results.

PCB Prototype Testing and Validation

Once the PCB prototype is fabricated, it must undergo rigorous testing and validation to ensure that it meets the desired specifications and functions as intended.

Visual Inspection

The first step in testing a PCB prototype is to perform a visual inspection. This process involves examining the board for any obvious defects, such as missing components, incorrect component placement, or damaged traces. Visual inspection can help identify issues that may have occurred during the fabrication process.

Continuity Testing

Continuity testing verifies that the electrical connections on the PCB are intact and that there are no short circuits or open connections. This testing can be performed using a multimeter or a dedicated Continuity Tester. Continuity testing is crucial for ensuring that the board’s electrical connections are reliable and free from defects.

Functional Testing

Functional testing involves powering up the PCB prototype and verifying that it performs the desired functions. This testing may include:

-

Power-on testing: Verifying that the board powers up correctly and that all components receive the appropriate voltage levels.

-

Signal integrity testing: Ensuring that the signals on the board are clean, stable, and free from interference or distortion.

-

Firmware testing: Verifying that the board’s firmware functions as intended and that it communicates correctly with other components in the system.

Functional testing is essential for validating the overall performance and reliability of the PCB prototype.

Environmental Testing

In some cases, PCB prototypes may need to undergo environmental testing to ensure that they can withstand the intended operating conditions. Environmental testing may include:

-

Temperature cycling: Exposing the board to extreme temperature variations to verify its performance and reliability under different thermal conditions.

-

Humidity testing: Subjecting the board to high humidity levels to ensure that it can operate reliably in moisture-rich environments.

-

Vibration testing: Testing the board’s resistance to mechanical vibrations to ensure that it can withstand the expected levels of shock and vibration in its intended application.

Environmental testing helps identify potential weaknesses in the PCB design and ensures that the board can perform reliably in its intended environment.

Compliance Testing

Depending on the intended application and target market, PCB prototypes may need to undergo compliance testing to ensure that they meet the relevant industry standards and regulations. Compliance testing may include:

-

Electromagnetic compatibility (EMC) testing: Verifying that the board does not generate excessive electromagnetic interference (EMI) and that it can operate reliably in the presence of external EMI.

-

Safety testing: Ensuring that the board meets the applicable safety standards, such as those related to electrical shock, fire hazards, and mechanical risks.

-

Environmental regulations: Verifying that the board complies with relevant environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive and the Waste Electrical and Electronic Equipment (WEEE) directive.

Compliance testing is critical for ensuring that the PCB prototype meets the necessary regulatory requirements and can be safely and legally marketed in its intended jurisdiction.

Best Practices for PCB Prototype Development

To ensure successful PCB prototype development, designers and engineers should follow several best practices:

1. Start with a Clear Specification

Before beginning the design process, create a clear and comprehensive specification that outlines the desired functionality, performance requirements, and constraints of the PCB prototype. A well-defined specification helps guide the design process and ensures that all stakeholders are aligned on the project goals.

2. Use Proven Components

When selecting components for the PCB prototype, choose proven, reliable parts with a track record of success in similar applications. This approach minimizes the risk of component-related issues and ensures that the prototype performs as expected.

3. Adhere to Design Guidelines

Follow industry-standard design guidelines and best practices when creating the schematic and PCB layout. These guidelines help ensure that the board is manufacturable, reliable, and compliant with relevant standards and regulations.

4. Collaborate with Manufacturers

Engage with PCB prototype manufacturers early in the design process to ensure that the board can be efficiently and cost-effectively produced. Manufacturers can provide valuable insights into design for manufacturability (DFM) and help optimize the design for the chosen fabrication process.

5. Perform Thorough Testing

Conduct comprehensive testing and validation of the PCB prototype to identify and address any issues before proceeding to mass production. This approach helps minimize the risk of costly redesigns and delays later in the development process.

6. Document the Design

Create and maintain accurate, up-to-date documentation of the PCB prototype design, including schematics, layout files, bill of materials (BOM), and test procedures. Proper documentation facilitates collaboration, troubleshooting, and future design iterations.

Frequently Asked Questions (FAQ)

-

Q: What is the typical turnaround time for PCB prototype fabrication?

A: The turnaround time for PCB prototype fabrication varies depending on the complexity of the design, the chosen fabrication method, and the manufacturer’s workload. Rapid prototyping techniques, such as 3D printing and milling, can produce prototypes in as little as 24 hours, while traditional fabrication methods may take several days to a few weeks. -

Q: How much does it cost to create a PCB prototype?

A: The cost of creating a PCB prototype depends on several factors, including the size and complexity of the board, the chosen fabrication method, and the number of prototypes required. Rapid prototyping techniques generally offer lower costs for small quantities, while traditional fabrication methods may be more cost-effective for larger runs. Prices can range from a few hundred to several thousand dollars, depending on the specific requirements of the project. -

Q: What are the most common issues encountered during PCB prototype development?

A: Some common issues encountered during PCB prototype development include component availability and compatibility problems, signal integrity issues, power distribution concerns, and manufacturing-related defects. Thorough design reviews, adherence to best practices, and comprehensive testing can help mitigate these issues. -

Q: How can I ensure that my PCB prototype meets the necessary regulatory requirements?

A: To ensure that your PCB prototype meets the necessary regulatory requirements, familiarize yourself with the relevant industry standards and regulations for your intended application and market. Engage with compliance testing laboratories and consultants to guide you through the compliance process and perform the necessary tests. -

Q: Can I use my PCB prototype for mass production?

A: While PCB prototypes are primarily used for design validation and testing, they can sometimes be used for small-scale production runs. However, it is essential to consider the manufacturing process used for the prototype and ensure that it is suitable for larger-scale production. In many cases, the design may need to be optimized for mass production to achieve the desired cost, quality, and reliability targets.

Conclusion

PCB prototypes play a crucial role in the development of electronic devices, allowing designers and engineers to test and validate their designs before committing to mass production. By following best practices and leveraging the appropriate fabrication techniques, companies can create high-quality PCB prototypes that streamline the development process and ensure the success of their products.

As the electronics industry continues to evolve, the importance of efficient and effective PCB prototyping will only continue to grow. By staying up-to-date with the latest technologies and techniques, and by fostering strong partnerships with experienced PCB prototype manufacturers, companies can position themselves for success in this dynamic and competitive landscape.

| PCB Prototyping Method | Advantages | Disadvantages |

|---|---|---|

| Traditional Fabrication | High-quality results, suitable for complex designs | Longer turnaround times, higher costs for small quantities |

| 3D Printing | Rapid prototyping, low cost for small quantities | Limited complexity, lower quality compared to traditional methods |

| PCB Milling | Fast turnaround times, suitable for simple to medium-complexity designs | Limited precision, not suitable for high-density designs |

| Laser Etching | High-precision results, fast turnaround times | Higher costs compared to other rapid prototyping methods |

By carefully considering the advantages and limitations of each PCB prototyping method, engineers can select the most appropriate approach for their specific project requirements, ensuring optimal results and a smooth development process.

No responses yet