What are PCB tolerances?

PCB Tolerances are the acceptable deviations from the nominal or desired values of different parameters on a PCB. These parameters include the size and position of holes, pads, traces, and other features. Tolerances are necessary because it is virtually impossible to manufacture a PCB with exact dimensions and placements due to limitations in materials, equipment, and processes.

Tolerances are typically specified as a plus or minus (±) value, indicating the maximum allowable variation from the nominal value. For example, if a hole diameter is specified as 1.0 mm with a tolerance of ±0.1 mm, the acceptable range for the hole diameter would be between 0.9 mm and 1.1 mm.

Why are PCB tolerances important?

PCB tolerances play a vital role in ensuring the functionality, reliability, and manufacturability of electronic devices. Some of the key reasons why PCB tolerances are important include:

-

Functionality: Proper tolerances ensure that components fit correctly and make reliable connections with the PCB. If the tolerances are too loose, components may not fit properly or make poor electrical contacts, leading to device malfunction.

-

Reliability: Tight tolerances help maintain the desired electrical properties of the PCB, such as impedance and signal integrity. This is particularly important for high-frequency and high-speed applications where even small variations can have a significant impact on performance.

-

Manufacturability: Adherence to PCB tolerances is essential for the efficient and cost-effective manufacturing of PCBs. Overly tight tolerances can increase production costs and lead times, while excessively loose tolerances may result in a higher rate of defects and rework.

-

Compatibility: PCB tolerances ensure compatibility between different components, such as connectors and sockets. Consistent tolerances across the industry allow for interchangeability and standardization of components from various manufacturers.

Factors affecting PCB tolerances

Several factors influence the achievable tolerances in PCB manufacturing. Understanding these factors can help designers and engineers make informed decisions when specifying tolerances for their PCB designs.

-

Manufacturing process: Different PCB manufacturing processes have varying capabilities in terms of achievable tolerances. For example, high-density interconnect (HDI) PCBs typically require tighter tolerances compared to standard PCBs due to their smaller feature sizes and higher complexity.

-

Material properties: The properties of the PCB substrate material, such as thermal expansion and mechanical stability, can affect the achievable tolerances. Some materials, like polyimide, offer better dimensional stability than others, like FR-4, allowing for tighter tolerances.

-

Board thickness: The thickness of the PCB can impact the achievable tolerances. Thinner boards may be more susceptible to warping and distortion, making it more challenging to maintain tight tolerances.

-

Copper weight: The thickness of the copper traces on the PCB, often referred to as copper weight, can influence the tolerances. Thicker copper traces may require larger minimum widths and spacings, affecting the overall tolerances.

-

Feature size: The size of the features on the PCB, such as trace widths, hole diameters, and pad sizes, can affect the achievable tolerances. Generally, smaller features require tighter tolerances to ensure proper functionality and manufacturability.

Common PCB tolerance specifications

PCB tolerances are typically specified for various features and parameters on the board. Some of the most common PCB tolerance specifications include:

-

Hole size and position: The diameter and location of drilled holes for through-hole components and vias.

-

Pad size and position: The dimensions and placement of component pads and solder mask openings.

-

Trace width and spacing: The width of the copper traces and the spacing between them.

-

Solder mask registration: The alignment and overlap of the solder mask with the copper features.

-

Silkscreen registration: The alignment and legibility of the silkscreen markings on the PCB.

-

Board outline: The overall dimensions and shape of the PCB.

The specific tolerance values for these parameters depend on various factors, such as the PCB class, manufacturing capabilities, and application requirements. Industry standards, such as IPC (Association Connecting Electronics Industries), provide guidelines and recommendations for PCB tolerances based on the desired performance and reliability levels.

Hole size and position tolerances

Hole size and position tolerances are critical for ensuring proper component fit and reliable electrical connections. The hole size tolerance specifies the acceptable range for the diameter of the drilled holes, while the position tolerance indicates the allowable deviation in the location of the hole center relative to its nominal position.

Typical hole size tolerances for standard PCBs range from ±0.05 mm to ±0.15 mm, depending on the hole diameter and the PCB class. For example, IPC Class 2 specifies a hole size tolerance of ±0.1 mm for holes with diameters between 0.6 mm and 2.0 mm.

Hole position tolerances are usually specified as a combined tolerance, taking into account both the x and y axes. Common hole position tolerances range from ±0.05 mm to ±0.25 mm, depending on the PCB class and the hole size.

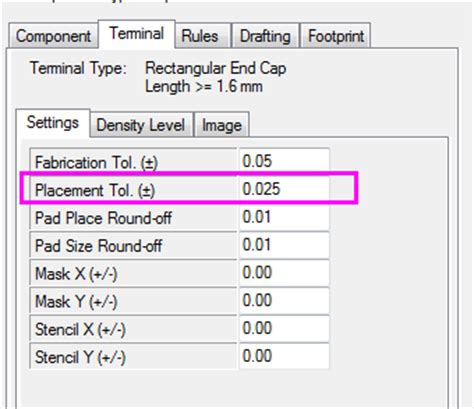

Pad size and position tolerances

Pad size and position tolerances are essential for ensuring proper component placement and solderability. The pad size tolerance specifies the acceptable range for the dimensions of the component pads, while the position tolerance indicates the allowable deviation in the location of the pad center relative to its nominal position.

Typical pad size tolerances for standard PCBs range from ±0.05 mm to ±0.15 mm, depending on the pad size and the PCB class. For example, IPC Class 2 specifies a pad size tolerance of ±0.1 mm for pads with dimensions between 0.8 mm and 1.6 mm.

Pad position tolerances are usually specified as a combined tolerance, similar to hole position tolerances. Common pad position tolerances range from ±0.05 mm to ±0.25 mm, depending on the PCB class and the pad size.

Trace width and spacing tolerances

Trace width and spacing tolerances are crucial for maintaining the desired electrical properties of the PCB, such as impedance and signal integrity. The trace width tolerance specifies the acceptable range for the width of the copper traces, while the spacing tolerance indicates the allowable deviation in the distance between adjacent traces.

Typical trace width tolerances for standard PCBs range from ±0.05 mm to ±0.15 mm, depending on the trace width and the PCB class. For example, IPC Class 2 specifies a trace width tolerance of ±0.1 mm for traces with widths between 0.2 mm and 0.4 mm.

Trace spacing tolerances are usually specified as a minimum value to ensure adequate isolation between traces. Common trace spacing tolerances range from 0.1 mm to 0.3 mm, depending on the PCB class and the voltage requirements.

| PCB Class | Trace Width (mm) | Trace Width Tolerance (±mm) | Trace Spacing (mm) |

|---|---|---|---|

| Class 1 | 0.2 – 0.4 | 0.15 | 0.2 |

| Class 2 | 0.2 – 0.4 | 0.1 | 0.15 |

| Class 3 | 0.1 – 0.2 | 0.05 | 0.1 |

Solder mask registration tolerances

Solder mask registration tolerances ensure the proper alignment and overlap of the solder mask with the copper features on the PCB. The solder mask registration tolerance specifies the acceptable deviation in the position of the solder mask openings relative to the underlying copper pads and traces.

Typical solder mask registration tolerances for standard PCBs range from ±0.05 mm to ±0.15 mm, depending on the PCB class and the feature size. For example, IPC Class 2 specifies a solder mask registration tolerance of ±0.1 mm for solder mask openings with dimensions between 0.8 mm and 1.6 mm.

Silkscreen registration tolerances

Silkscreen registration tolerances ensure the proper alignment and legibility of the silkscreen markings on the PCB. The silkscreen registration tolerance specifies the acceptable deviation in the position of the silkscreen features relative to the underlying copper features and solder mask openings.

Typical silkscreen registration tolerances for standard PCBs range from ±0.1 mm to ±0.3 mm, depending on the PCB class and the feature size. For example, IPC Class 2 specifies a silkscreen registration tolerance of ±0.2 mm for silkscreen features with line widths between 0.2 mm and 0.4 mm.

Board outline tolerances

Board outline tolerances ensure the overall dimensions and shape of the PCB are within acceptable limits. The board outline tolerance specifies the acceptable deviation in the size and contour of the PCB relative to its nominal dimensions.

Typical board outline tolerances for standard PCBs range from ±0.1 mm to ±0.5 mm, depending on the PCB size and the manufacturing process. For example, a common board outline tolerance for a 100 mm x 100 mm PCB is ±0.2 mm.

Achieving tighter PCB tolerances

In some cases, applications may require tighter PCB tolerances than the standard values. Achieving tighter tolerances often involves additional manufacturing processes, specialized equipment, and increased production costs. Some strategies for achieving tighter PCB tolerances include:

-

High-precision drilling: Using high-speed, high-precision drilling machines with advanced motion control systems can help achieve tighter hole size and position tolerances.

-

Laser drilling: Employing laser drilling technology for micro-vias and small holes can enable tighter tolerances and smaller feature sizes compared to mechanical drilling.

-

Advanced imaging: Using high-resolution imaging systems, such as direct imaging (DI) or laser direct imaging (LDI), can improve the registration and resolution of the solder mask and silkscreen features.

-

Controlled impedance: Implementing controlled impedance manufacturing processes, such as using specialized materials and precise trace geometries, can help maintain tighter trace width and spacing tolerances for high-speed applications.

-

Specialized materials: Utilizing advanced PCB Substrate Materials with better dimensional stability and thermal properties, such as polyimide or high-Tg FR-4, can help achieve tighter tolerances.

It is important to note that achieving tighter tolerances often comes with increased production costs and lead times. Designers and engineers should carefully consider the specific requirements of their application and work closely with the PCB manufacturer to determine the most cost-effective solution.

PCB tolerance stackup analysis

PCB tolerance stackup analysis is the process of evaluating the cumulative effect of individual tolerances on the overall dimensions and positions of features on the PCB. This analysis is essential for ensuring that the final assembled PCB meets the desired functionality and reliability requirements.

Tolerance stackup analysis takes into account the tolerances of various parameters, such as hole sizes, pad sizes, trace widths, and layer registration. By considering the worst-case scenarios, where the tolerances accumulate in the same direction, designers can identify potential issues and make necessary adjustments to the PCB design or manufacturing process.

There are several methods for performing PCB tolerance stackup analysis, including:

-

Worst-case analysis: This method considers the extreme values of each tolerance and calculates the maximum and minimum possible dimensions of the PCB features. While this approach provides a conservative estimate, it may result in overly restrictive tolerances and increased production costs.

-

Statistical analysis: This method uses statistical techniques, such as root-sum-square (RSS) or Monte Carlo simulations, to calculate the probability distribution of the PCB feature dimensions based on the individual tolerances. Statistical analysis provides a more realistic assessment of the likely outcomes and can help optimize the tolerances for cost and manufacturability.

-

Computer-aided tolerance analysis: Many PCB design software packages include tools for performing automated tolerance stackup analysis. These tools can quickly evaluate the impact of tolerances on the PCB design and provide recommendations for optimization.

Regularly performing PCB tolerance stackup analysis throughout the design process can help identify and mitigate potential issues early on, reducing the risk of costly redesigns and production delays.

Frequently Asked Questions (FAQ)

- What is the difference between nominal value and tolerance?

The nominal value is the desired or intended value of a parameter, such as a hole diameter or trace width. The tolerance is the acceptable range of deviation from the nominal value, typically specified as a plus or minus (±) value. For example, if the nominal hole diameter is 1.0 mm with a tolerance of ±0.1 mm, the acceptable range for the hole diameter would be between 0.9 mm and 1.1 mm.

- How do PCB tolerances affect the cost of manufacturing?

Tighter PCB tolerances generally increase the cost of manufacturing due to the need for more precise equipment, specialized processes, and higher-quality materials. Achieving tighter tolerances may also require additional inspection and quality control measures, further increasing production costs. It is important to specify tolerances that are appropriate for the application requirements while considering the impact on manufacturing costs.

- What are the most common PCB tolerance standards?

The most widely recognized PCB tolerance standards are those published by the IPC (Association Connecting Electronics Industries). The IPC Standards, such as IPC-6012 and IPC-2615, provide guidelines and requirements for various aspects of PCB design and manufacturing, including tolerances for different PCB classes and feature sizes. Other organizations, such as the European Space Agency (ESA) and the military (MIL-PRF-55110), also have their own PCB tolerance standards for specific applications.

- How can I ensure that my PCB design meets the required tolerances?

To ensure that your PCB design meets the required tolerances, follow these steps:

a. Clearly specify the desired tolerances for all critical features in the PCB design documentation.

b. Perform PCB tolerance stackup analysis to evaluate the impact of individual tolerances on the overall design.

c. Work closely with the PCB manufacturer to review the design and discuss any potential issues or limitations related to tolerances.

d. Consider the manufacturing capabilities and costs when specifying tolerances, and make adjustments as necessary to balance performance, reliability, and cost.

e. Regularly communicate with the PCB manufacturer throughout the production process to ensure that the tolerances are being met and to address any issues that may arise.

- What should I do if my PCB design requires tighter tolerances than the standard values?

If your PCB design requires tighter tolerances than the standard values, take the following steps:

a. Discuss your specific requirements with the PCB manufacturer and assess their capability to achieve the desired tolerances.

b. Consider alternative manufacturing processes, such as high-precision drilling, laser drilling, or advanced imaging, that can enable tighter tolerances.

c. Evaluate the use of specialized materials with better dimensional stability and thermal properties to help achieve tighter tolerances.

d. Be prepared to incur additional manufacturing costs and longer lead times associated with achieving tighter tolerances.

e. Perform thorough testing and validation of the PCB design to ensure that the tighter tolerances meet the performance and reliability requirements of the application.

Conclusion

PCB tolerance is a critical aspect of PCB design and manufacturing that ensures the proper functionality, reliability, and manufacturability of electronic devices. Understanding the typical tolerances for various PCB features, such as hole sizes, pad sizes, trace widths, and spacing, is essential for designers and engineers to create high-quality and cost-effective PCBs.

Factors such as manufacturing processes, material properties, board thickness, copper weight, and feature sizes can all influence the achievable tolerances. Industry standards, such as those published by the IPC, provide guidelines and recommendations for PCB tolerances based on the desired performance and reliability levels.

Achieving tighter PCB tolerances often involves specialized manufacturing processes, advanced equipment, and increased production costs. Designers and engineers should carefully consider the specific requirements of their application and work closely with the PCB manufacturer to determine the most cost-effective solution.

Performing regular PCB tolerance stackup analysis throughout the design process can help identify and mitigate potential issues early on, reducing the risk of costly redesigns and production delays. By understanding and adhering to PCB tolerances, designers and manufacturers can create high-quality, reliable, and cost-effective PCBs for a wide range of electronic applications.

No responses yet