Introduction to PCB Current Calculator

A PCB current calculator is an essential tool for engineers and designers working on printed circuit boards (PCBs). It allows you to accurately determine the current-carrying capacity of the traces on your PCB, ensuring that your design can handle the required current without overheating or experiencing voltage drop issues. In this article, we will dive deep into the world of PCB current calculators, exploring their importance, how they work, and how to use them effectively in your PCB design process.

Why Is PCB Current Calculator Important?

Ensuring Proper Current-Carrying Capacity

One of the primary reasons to use a PCB current calculator is to ensure that the traces on your PCB can handle the required current. If the traces are too thin or too narrow, they may not be able to carry the necessary current, leading to overheating, voltage drop, and potential failure of the circuit. By using a PCB current calculator, you can determine the appropriate trace width and thickness for your design, ensuring that it can handle the required current without issues.

Preventing Voltage Drop

Another important reason to use a PCB current calculator is to prevent voltage drop. When current flows through a trace, there is always some resistance, which can cause a voltage drop along the length of the trace. If the voltage drop is too high, it can affect the performance of the circuit, leading to issues such as signal integrity problems or even complete failure. By using a PCB current calculator, you can determine the appropriate trace width and thickness to minimize voltage drop and ensure that your circuit performs as intended.

Optimizing PCB Design

Using a PCB current calculator can also help you optimize your PCB design. By determining the appropriate trace width and thickness for your design, you can minimize the amount of copper used on the board, reducing manufacturing costs and improving signal integrity. Additionally, by using a PCB current calculator, you can identify areas where you may need to use thicker traces or multiple layers to handle high-current signals, allowing you to create a more robust and reliable design.

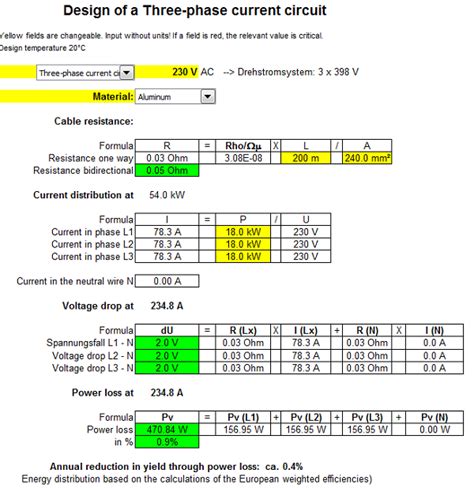

How Does a PCB Current Calculator Work?

Current-Carrying Capacity Formulas

At the heart of any PCB current calculator are formulas that determine the current-carrying capacity of a trace based on its width, thickness, and temperature rise. The most commonly used formula for this purpose is the IPC-2152 standard, which was developed by the Association Connecting Electronics Industries (IPC) to provide a standardized method for calculating current-carrying capacity.

The IPC-2152 formula takes into account several factors, including:

- Trace width

- Trace thickness

- Copper weight

- Temperature rise

- Ambient temperature

- Number of layers

- Via size and spacing

By inputting these parameters into the IPC-2152 formula, a PCB current calculator can determine the maximum current that a trace can safely carry without overheating or experiencing voltage drop issues.

Online PCB Current Calculators

While it is possible to calculate the current-carrying capacity of a trace manually using the IPC-2152 formula, it can be a time-consuming and error-prone process. Fortunately, there are many online PCB current calculators available that can perform these calculations quickly and accurately.

Most online PCB current calculators work by allowing you to input the relevant parameters for your design, such as trace width, thickness, and temperature rise. The calculator then uses these inputs to determine the maximum current that the trace can safely carry, as well as other important metrics such as resistance and voltage drop.

Some popular online PCB current calculators include:

- Advanced Circuits’ PCB Trace Width Calculator

- EEWeb’s PCB Trace Width Calculator

- Saturn PCB Toolkit’s Current Carrying Capacity Calculator

These calculators are easy to use and provide a convenient way to quickly determine the current-carrying capacity of your traces without the need for manual calculations.

PCB Design Software with Integrated Current Calculators

In addition to online PCB current calculators, many PCB design software packages include integrated current calculators as part of their toolset. These integrated calculators allow you to quickly and easily determine the current-carrying capacity of your traces directly within the design environment, without the need to switch to a separate tool.

Some popular PCB design software packages with integrated current calculators include:

- Altium Designer

- Eagle PCB

- KiCad

These integrated calculators work similarly to online calculators, allowing you to input the relevant parameters for your design and quickly determine the current-carrying capacity of your traces. However, they offer the added convenience of being directly integrated into the design environment, allowing you to make changes to your design on the fly based on the results of the calculator.

How to Use a PCB Current Calculator Effectively

Understanding the Input Parameters

To use a PCB current calculator effectively, it is important to understand the input parameters and how they affect the current-carrying capacity of your traces. Some of the key parameters to consider include:

- Trace width: The width of the trace, typically measured in mils or millimeters.

- Trace thickness: The thickness of the copper layer, typically measured in ounces per square foot or microns.

- Copper weight: The weight of the copper used in the PCB, typically measured in ounces per square foot.

- Temperature rise: The maximum allowable temperature rise above ambient for the trace.

- Ambient temperature: The temperature of the environment in which the PCB will be operating.

- Number of layers: The number of copper layers in the PCB.

- Via size and spacing: The size and spacing of any vias used in the design.

By understanding these parameters and how they affect the current-carrying capacity of your traces, you can make informed decisions about your PCB design and ensure that it can handle the required current without issues.

Interpreting the Results

Once you have input the relevant parameters into the PCB current calculator, it will provide you with the results, typically in the form of a maximum current value for the trace. It is important to interpret these results correctly to ensure that your design is safe and reliable.

One key thing to keep in mind is that the maximum current value provided by the calculator is just that – a maximum. It is generally a good idea to design your traces to carry somewhat less than this maximum value to provide a safety margin and ensure that your design can handle any unexpected variations in current or temperature.

Another important consideration is the effect of temperature on the current-carrying capacity of your traces. As the temperature of the PCB increases, the current-carrying capacity of the traces decreases. This means that if your PCB will be operating in a high-temperature environment, you may need to use thicker or wider traces to ensure that they can handle the required current without overheating.

Applying the Results to Your PCB Design

Once you have interpreted the results of the PCB current calculator, you can apply them to your PCB design to ensure that it can handle the required current safely and reliably. Some key things to consider when applying the results include:

- Trace width and thickness: Use the results of the calculator to determine the appropriate trace width and thickness for your design. Keep in mind that using wider or thicker traces than necessary can increase manufacturing costs and decrease signal integrity, so it is important to strike a balance between current-carrying capacity and other design considerations.

- Via size and spacing: If your design includes vias, use the results of the calculator to determine the appropriate via size and spacing to ensure that they can handle the required current without overheating.

- Layer stackup: Consider using multiple layers or a thicker copper weight to increase the current-carrying capacity of your traces, particularly for high-current signals.

- Thermal management: Use the results of the calculator to determine if additional thermal management techniques, such as the use of thermal vias or heatsinks, are necessary to ensure that your design can handle the required current without overheating.

By applying the results of the PCB current calculator to your design in this way, you can ensure that your PCB can handle the required current safely and reliably, while also optimizing other aspects of the design such as signal integrity and manufacturing cost.

Frequently Asked Questions (FAQ)

1. What is a PCB current calculator?

A PCB current calculator is a tool that helps determine the current-carrying capacity of traces on a printed circuit board (PCB) based on factors such as trace width, thickness, copper weight, temperature rise, and ambient temperature.

2. Why is it important to use a PCB current calculator?

Using a PCB current calculator is important to ensure that the traces on your PCB can handle the required current without overheating or experiencing voltage drop issues. It helps you design a safe, reliable, and optimized PCB by determining the appropriate trace width and thickness for your specific requirements.

3. What are the key parameters to consider when using a PCB current calculator?

The key parameters to consider when using a PCB current calculator include trace width, trace thickness, copper weight, temperature rise, ambient temperature, number of layers, and via size and spacing. Understanding how these parameters affect the current-carrying capacity of your traces is crucial for making informed design decisions.

4. How do I interpret the results of a PCB current calculator?

The results of a PCB current calculator typically provide the maximum current value that a trace can safely carry. It is important to design your traces to carry somewhat less than this maximum value to provide a safety margin and account for unexpected variations in current or temperature. Additionally, consider the effect of temperature on the current-carrying capacity of your traces, especially if your PCB will be operating in a high-temperature environment.

5. How can I apply the results of a PCB current calculator to my PCB design?

To apply the results of a PCB current calculator to your PCB design, use the calculated values to determine the appropriate trace width and thickness, via size and spacing, and layer stackup. Consider using multiple layers or a thicker copper weight for high-current signals, and implement thermal management techniques such as thermal vias or heatsinks if necessary. By applying the results of the calculator to your design, you can ensure that your PCB can handle the required current safely and reliably while optimizing other aspects of the design.

Conclusion

A PCB current calculator is an essential tool for anyone involved in the design of printed circuit boards. By using a current calculator, you can ensure that your PCB design can handle the required current safely and reliably, while also optimizing other aspects of the design such as signal integrity and manufacturing cost.

To use a PCB current calculator effectively, it is important to understand the input parameters and how they affect the current-carrying capacity of your traces. By interpreting the results of the calculator correctly and applying them to your design, you can create a PCB that meets your specific requirements and performs as intended.

Whether you choose to use an online calculator, an integrated calculator in your PCB design software, or perform the calculations manually using the IPC-2152 formula, a PCB current calculator is an indispensable tool for anyone involved in PCB design. By using a current calculator as part of your design process, you can create PCBs that are safe, reliable, and optimized for your specific application.

No responses yet