How Do Pre-heaters Work?

Pre-heaters work by transferring heat from a heating medium to the substance that needs to be heated. The heating medium can be steam, hot water, exhaust gases, or any other suitable heat source. The substance to be heated passes through tubes or plates within the pre-heater, while the heating medium flows around these tubes or plates, facilitating heat transfer.

The most common types of pre-heaters include:

- Shell and tube pre-heaters

- Plate heat exchangers

- Regenerative pre-heaters

- Electric pre-heaters

The choice of pre-heater depends on factors such as the nature of the substance being heated, the required temperature rise, and the available heat source.

Functions of Pre-heaters

1. Enhancing Process Efficiency

One of the primary functions of a pre-heater is to enhance the efficiency of industrial processes. By raising the temperature of a substance before it enters the main processing unit, pre-heaters reduce the amount of energy required to achieve the desired temperature within the main unit. This results in improved overall process efficiency and reduced energy consumption.

For example, in a chemical reactor, pre-heating the reactants before they enter the reactor can significantly reduce the energy required to maintain the reaction temperature. This is because the reactants are already at an elevated temperature, and less additional heat input is necessary to sustain the reaction.

2. Optimizing Energy Consumption

Pre-heaters play a crucial role in optimizing energy consumption in various industrial processes. By recovering waste heat from one part of the process and using it to pre-heat the incoming substance, pre-heaters minimize the need for additional energy input. This concept, known as heat integration or heat recovery, is widely used in industries to reduce energy costs and improve overall energy efficiency.

For instance, in a power plant, the exhaust gases from the turbine can be used to pre-heat the feed water entering the boiler. This reduces the amount of fuel required to generate steam, thereby improving the plant’s energy efficiency and reducing its carbon footprint.

3. Improving Product Quality

Pre-heaters can also contribute to improving product quality by ensuring that the substance being processed reaches the desired temperature uniformly. Uneven heating can lead to variations in product quality, which can be detrimental in certain industries, such as food processing or pharmaceutical manufacturing.

By pre-heating the substance to a uniform temperature before it enters the main processing unit, pre-heaters help maintain consistent product quality. This is particularly important in processes where temperature plays a critical role in determining the final product’s properties, such as viscosity, texture, or chemical composition.

4. Protecting Equipment

Another important function of pre-heaters is to protect downstream equipment from thermal shock or excessive wear. When a cold substance suddenly comes into contact with hot equipment, it can cause rapid temperature changes, leading to thermal stress and potential damage to the equipment. Pre-heaters gradually raise the temperature of the substance, reducing the risk of thermal shock and prolonging the life of the equipment.

In the oil and gas industry, for example, pre-heaters are used to warm up crude oil before it enters the refining process. This is necessary because crude oil often contains wax and other high-melting-point components that can solidify and clog pipelines and equipment if not heated adequately. By pre-heating the crude oil, these issues can be avoided, ensuring smooth operation and reduced maintenance requirements.

5. Facilitating Chemical Reactions

Pre-heaters are also used to facilitate chemical reactions by bringing the reactants to the required temperature before they enter the reactor. Many chemical reactions have a specific temperature range in which they occur optimally. Pre-heating the reactants ensures that they are at the appropriate temperature when they come into contact, promoting efficient and complete reactions.

In the production of ammonia, for instance, the reactants (nitrogen and hydrogen) must be heated to a temperature of around 400-500°C before entering the reactor. Pre-heaters are used to achieve this temperature, enabling the reaction to proceed effectively and ensuring a high yield of ammonia.

Applications of Pre-heaters

Pre-heaters find applications in a wide range of industries, including:

- Chemical processing

- Oil and gas refineries

- Power generation

- Food and beverage processing

- Pulp and paper mills

- Textile manufacturing

- Pharmaceutical production

The table below provides a summary of some common applications of pre-heaters in various industries:

| Industry | Application | Purpose |

|---|---|---|

| Chemical processing | Reactant pre-heating | Facilitating chemical reactions and improving process efficiency |

| Oil and gas refineries | Crude oil pre-heating | Preventing wax formation and protecting equipment |

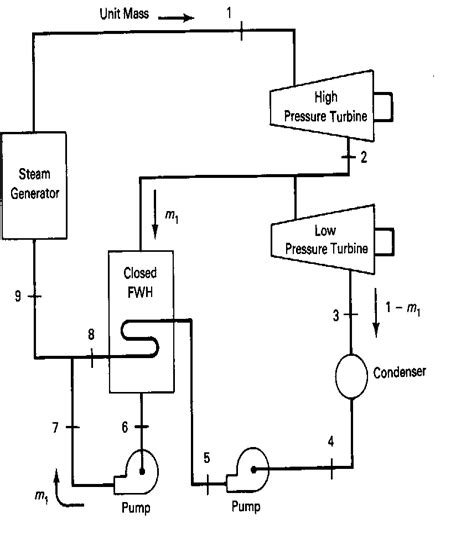

| Power generation | Feed water pre-heating | Optimizing energy consumption and improving plant efficiency |

| Food and beverage processing | Product pre-heating | Ensuring uniform heating and maintaining product quality |

| Pulp and paper mills | Pulp slurry pre-heating | Reducing energy consumption and improving paper quality |

| Textile manufacturing | Dye solution pre-heating | Ensuring consistent dyeing and reducing energy costs |

| Pharmaceutical production | Raw material pre-heating | Facilitating chemical reactions and maintaining product quality |

Benefits of Pre-heaters

The use of pre-heaters offers numerous benefits, including:

- Reduced energy consumption and costs

- Improved process efficiency

- Enhanced product quality and consistency

- Prolonged equipment life

- Facilitation of chemical reactions

- Reduced environmental impact through heat recovery and energy optimization

By incorporating pre-heaters into industrial processes, companies can achieve significant cost savings, improve their overall performance, and contribute to a more sustainable future.

Frequently Asked Questions (FAQ)

1. What is the difference between a pre-heater and a heat exchanger?

A pre-heater is a specific type of heat exchanger that is used to heat a substance before it enters a main processing unit. Heat exchangers, on the other hand, are a broader category of devices that facilitate heat transfer between two fluids without direct contact. While all pre-heaters are heat exchangers, not all heat exchangers are pre-heaters.

2. Can pre-heaters be used for cooling purposes?

Although pre-heaters are primarily used for heating purposes, they can also be used for cooling in some cases. For example, in a process where a hot substance needs to be cooled before entering a specific unit, a pre-heater can be used to transfer heat from the hot substance to a cooling medium, effectively pre-cooling the substance.

3. How do I select the right type of pre-heater for my application?

The selection of a pre-heater depends on several factors, including the nature of the substance being heated, the required temperature rise, the available heat source, and the process conditions. It is essential to consider aspects such as the heat transfer rate, pressure drop, fouling tendency, and material compatibility when choosing a pre-heater. Consulting with a heat transfer specialist or an equipment manufacturer can help in making the right choice.

4. How often do pre-heaters require maintenance?

The maintenance frequency of pre-heaters depends on factors such as the nature of the fluids being processed, the operating conditions, and the pre-heater design. In general, pre-heaters should be inspected and cleaned periodically to remove any fouling or scaling that may have accumulated on the heat transfer surfaces. The specific maintenance schedule will vary depending on the application and should be determined based on the manufacturer’s recommendations and the plant’s operating experience.

5. Can pre-heaters be retrofitted into existing industrial processes?

Yes, pre-heaters can be retrofitted into existing industrial processes to improve energy efficiency and overall performance. However, the feasibility and cost-effectiveness of retrofitting a pre-heater will depend on factors such as the available space, the compatibility with existing equipment, and the potential energy savings. A thorough feasibility study should be conducted to assess the technical and economic viability of retrofitting a pre-heater in a given process.

Conclusion

Pre-heaters are essential components in various industrial processes, serving multiple functions that contribute to improved efficiency, energy optimization, product quality, and equipment protection. By understanding the working principles, applications, and benefits of pre-heaters, industries can make informed decisions about incorporating these devices into their processes.

As the world moves towards a more sustainable future, the use of pre-heaters will continue to play a crucial role in reducing energy consumption, minimizing environmental impact, and enhancing overall process performance. By embracing innovative heat transfer technologies and optimizing the use of pre-heaters, industries can not only improve their bottom line but also contribute to a greener and more efficient future.

No responses yet