Introduction to PCB Assembly

PCB assembly, also known as PCBA (Printed Circuit Board Assembly), is the process of soldering or assembling electronic components onto a printed circuit board (PCB). It is a crucial step in the manufacturing of electronic devices, as it involves the integration of various components such as resistors, capacitors, integrated circuits (ICs), and connectors onto the PCB to create a functional electronic circuit.

PCBs are the backbone of modern electronics, providing a platform for components to be connected and communicate with each other. They are found in a wide range of devices, from smartphones and computers to medical equipment and automotive systems.

The Importance of PCB Assembly

PCB assembly plays a vital role in the electronics industry for several reasons:

- Functionality: Proper PCB assembly ensures that electronic components are correctly placed and connected, enabling the device to function as intended.

- Reliability: Well-assembled PCBs are more reliable and have a lower risk of failure, which is crucial for mission-critical applications such as medical devices and aerospace systems.

- Miniaturization: PCB assembly allows for the compact arrangement of components, enabling the creation of smaller and more portable electronic devices.

- Cost-effectiveness: Automated PCB assembly processes, such as surface mount technology (SMT), enable high-volume production at a lower cost compared to manual assembly methods.

The PCB Assembly Process

The PCB assembly process typically involves several steps, which can vary depending on the complexity of the board and the specific requirements of the project. However, the general process flow is as follows:

1. Solder Paste Application

Solder paste, a mixture of tiny solder particles suspended in a flux medium, is applied to the PCB’s pads using a stencil or screen printing process. The stencil ensures that the solder paste is deposited accurately and consistently on the pads.

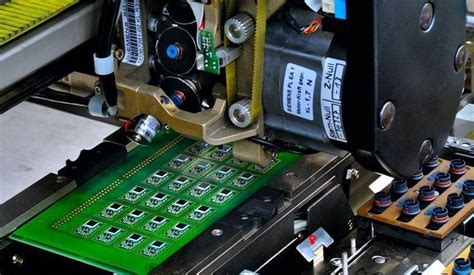

2. Component Placement

Surface Mount Devices (SMDs) are placed onto the solder paste-covered pads using a pick-and-place machine. These machines use computer-controlled nozzles to accurately position components on the board at high speeds.

3. Reflow Soldering

The PCB with the placed components is then passed through a reflow oven, which heats the board to a specific temperature profile. This melts the solder paste, creating a permanent electrical and mechanical connection between the components and the PCB.

4. Inspection and Testing

After reflow soldering, the assembled PCB undergoes visual inspection and automated optical inspection (AOI) to identify any defects or misaligned components. Electrical testing, such as in-circuit testing (ICT) or functional testing, is also performed to ensure that the board functions as intended.

5. Through-hole Component Insertion and Wave Soldering (if required)

If the PCB design includes through-hole components, they are inserted manually or by a machine into the designated holes on the board. The PCB then passes through a wave soldering machine, which applies molten solder to the bottom side of the board, creating a connection between the through-hole component leads and the PCB.

6. Final Inspection and Packaging

The assembled PCB undergoes a final visual inspection and functional testing to ensure that it meets the required specifications. The board is then cleaned, conformal coated (if required), and packaged for shipment.

Surface Mount Technology (SMT) vs. Through-hole Technology (THT)

PCB assembly can be categorized into two main technologies: surface mount technology (SMT) and through-hole technology (THT). Each method has its advantages and disadvantages, and the choice between them depends on factors such as the component types, board density, and production volume.

Surface Mount Technology (SMT)

SMT involves placing components directly onto the surface of the PCB. The components, known as surface mount devices (SMDs), have small metal leads or terminations that are soldered to pads on the PCB’s surface.

Advantages of SMT:

1. Higher component density: SMDs are smaller than through-hole components, allowing for more components to be placed on a given board area.

2. Faster assembly: Automated SMT assembly processes enable higher production speeds and lower labor costs.

3. Better performance: Shorter lead lengths in SMDs result in reduced parasitic inductance and capacitance, improving high-frequency performance.

Disadvantages of SMT:

1. Higher setup costs: SMT assembly requires specialized equipment, such as stencil printers, pick-and-place machines, and reflow ovens, which can be expensive.

2. Difficulty in manual rework: Due to the small size of SMDs, manual rework and repair can be challenging and require skilled technicians.

Through-hole Technology (THT)

THT involves inserting component leads through holes drilled in the PCB and soldering them to pads on the opposite side of the board.

Advantages of THT:

1. Stronger mechanical bonds: Through-hole components have longer leads that provide stronger mechanical connections to the PCB.

2. Easier manual assembly and rework: Through-hole components are larger and easier to handle, making manual assembly and rework more straightforward.

3. Better for high-power applications: Through-hole components can dissipate more heat due to their larger size and greater contact area with the PCB.

Disadvantages of THT:

1. Lower component density: Through-hole components occupy more board space, limiting the number of components that can be placed on a given area.

2. Slower assembly: Manual insertion of through-hole components is time-consuming, and automated insertion is slower compared to SMT placement.

3. Higher drilling costs: THT requires holes to be drilled in the PCB, which adds to the manufacturing cost and time.

Many modern PCB designs use a combination of SMT and THT, known as mixed-technology assembly. This approach allows designers to leverage the benefits of both technologies while minimizing their drawbacks.

Custom PCB Assembly

Custom PCB assembly refers to the process of assembling PCBs according to a customer’s specific requirements, such as component selection, board layout, and manufacturing specifications. This is in contrast to standard or off-the-shelf PCB assembly, where the PCB design and components are predetermined.

Advantages of Custom PCB Assembly

- Tailored to specific needs: Custom PCB assembly allows for the creation of electronic devices that are optimized for a particular application, ensuring better performance and reliability.

- Flexibility in design: Customers have complete control over the PCB design, enabling them to incorporate unique features and functionalities that may not be available in standard PCB assemblies.

- Cost-effectiveness for high-volume production: Custom PCB assembly can be more cost-effective for high-volume production runs, as the design can be optimized for manufacturing efficiency and Component sourcing.

- Intellectual property protection: Custom PCB designs can help protect a company’s intellectual property by making it more difficult for competitors to copy or reverse-engineer their products.

Considerations for Custom PCB Assembly

When opting for custom PCB assembly, there are several factors to consider:

- Design complexity: Complex PCB designs may require more advanced manufacturing capabilities and longer lead times, which can impact cost and time-to-market.

- Component availability: Custom designs may require specific components that have longer lead times or are more difficult to source, which can affect the overall production schedule.

- Manufacturing partner selection: Choosing a reliable and experienced PCB assembly partner is crucial to ensure that the custom PCBs are manufactured to the required quality standards and delivered on time.

- Testing and validation: Custom PCB assemblies may require additional testing and validation to ensure that they meet the specified performance and reliability requirements.

Choosing a PCB Assembly Partner

Selecting the right PCB assembly partner is essential for the successful production of custom PCBs. Consider the following factors when choosing a PCB assembly partner:

- Technical capabilities: Ensure that the partner has the necessary equipment, expertise, and experience to handle your specific PCB assembly requirements, such as SMT, THT, or mixed-technology assembly.

- Quality management: Look for a partner with a robust quality management system, such as ISO 9001 certification, and a track record of producing high-quality PCB assemblies.

- Manufacturing capacity: Verify that the partner has sufficient production capacity to meet your volume requirements and can scale up production as needed.

- Communication and support: Choose a partner that maintains clear and open communication channels, provides regular project updates, and offers technical support throughout the production process.

- Pricing and lead times: Compare pricing and lead times from multiple potential partners to ensure that you are getting a competitive offer that meets your budget and time-to-market goals.

- Intellectual property protection: If your custom PCB design contains sensitive or proprietary information, ensure that the partner has adequate measures in place to protect your intellectual property.

FAQs

- What is the difference between PCB and PCBA?

PCB (Printed Circuit Board) refers to the Bare Board without any components attached, while PCBA (Printed Circuit Board Assembly) refers to the PCB with electronic components soldered onto it, forming a complete functional circuit. - What are the main steps in the PCB assembly process?

The main steps in the PCB assembly process are: - Solder paste application

- Component placement

- Reflow soldering

- Inspection and testing

- Through-hole component insertion and wave soldering (if required)

- Final inspection and packaging

- What are the advantages of surface mount technology (SMT) over through-hole technology (THT)?

The advantages of SMT over THT include: - Higher component density

- Faster assembly

- Better performance due to shorter lead lengths

- What factors should I consider when choosing a PCB assembly partner for custom PCBs?

When choosing a PCB assembly partner for custom PCBs, consider the following factors: - Technical capabilities

- Quality management

- Manufacturing capacity

- Communication and support

- Pricing and lead times

- Intellectual property protection

- How can custom PCB assembly benefit my business?

Custom PCB assembly can benefit your business in several ways: - Tailored to your specific needs, ensuring better performance and reliability

- Flexibility in design to incorporate unique features and functionalities

- Cost-effectiveness for high-volume production runs

- Protection of your intellectual property by making it more difficult for competitors to copy or reverse-engineer your products

Conclusion

PCB assembly is a critical process in the manufacturing of electronic devices, involving the soldering of components onto a printed circuit board. Understanding the various aspects of PCB assembly, such as SMT and THT, as well as the benefits and considerations of custom PCB assembly, is essential for businesses looking to create optimized and reliable electronic products.

When embarking on a custom PCB assembly project, it is crucial to choose an experienced and reliable manufacturing partner that can meet your specific requirements while ensuring high quality and timely delivery. By carefully considering the factors outlined in this article, you can make an informed decision and set your custom PCB assembly project up for success.

No responses yet