Introduction to PCB Substrate

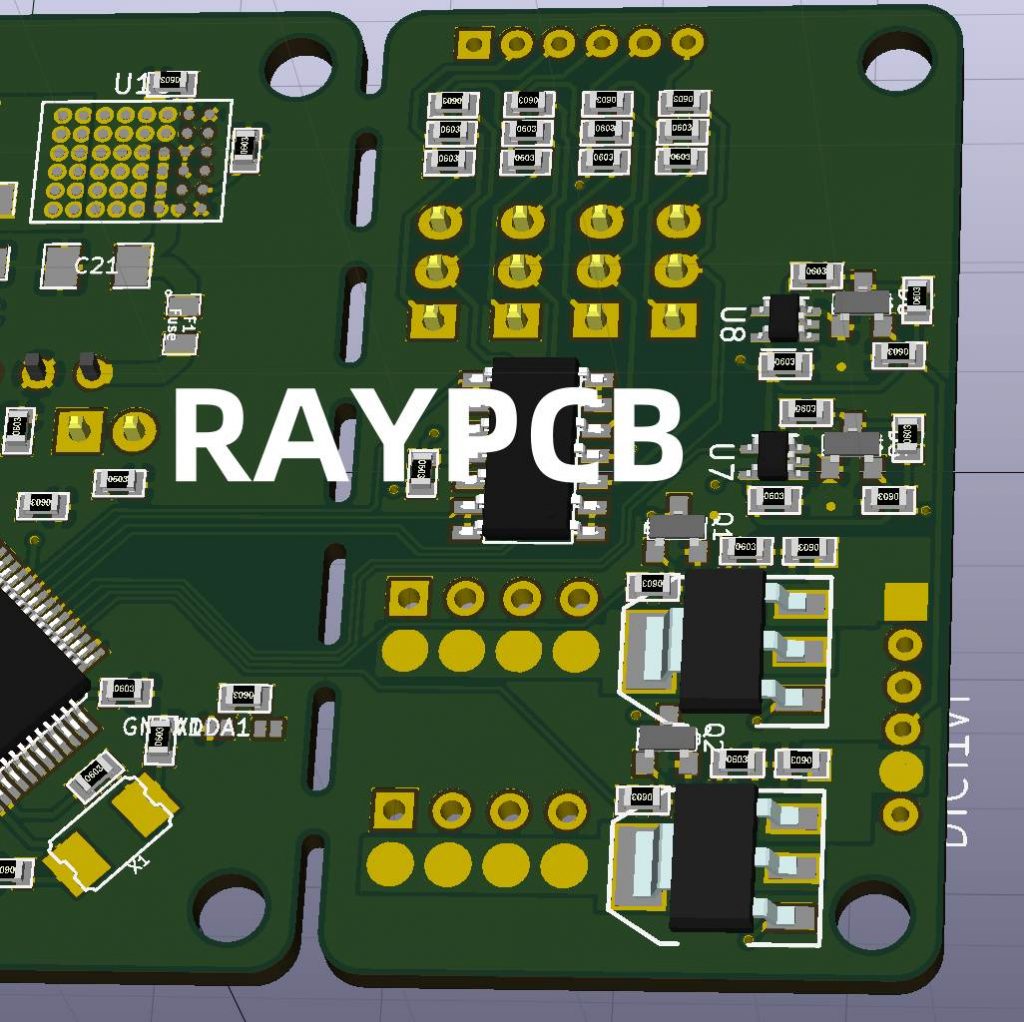

Printed Circuit Boards (PCBs) are essential components in modern electronic devices, providing a platform for mounting and interconnecting electronic components. The performance, reliability, and functionality of a PCB heavily depend on the choice of substrate material. In this article, we will delve into the world of PCB Substrate Materials, exploring their properties, types, and applications.

Understanding PCB Substrate

A PCB substrate is the base material on which the conductive traces, pads, and other features are printed or etched. It serves as the foundation for the electronic circuit, providing mechanical support, electrical insulation, and heat dissipation. The choice of substrate material is crucial as it directly affects the PCB’s electrical, thermal, and mechanical characteristics.

Properties of PCB Substrate Materials

When selecting a PCB substrate material, several key properties must be considered:

- Dielectric Constant (Dk): The dielectric constant is a measure of a material’s ability to store electrical energy. A lower Dk value is desirable for high-frequency applications as it reduces signal propagation delay and minimizes signal loss.

- Dissipation Factor (Df): The dissipation factor represents the amount of energy lost as heat when an electrical signal passes through the substrate material. A lower Df value is preferred to minimize signal loss and maintain signal integrity.

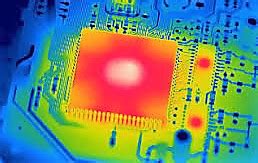

- Thermal Conductivity: Thermal conductivity refers to a material’s ability to conduct heat. A higher thermal conductivity helps in dissipating heat generated by electronic components, preventing thermal stress and ensuring better performance.

- Coefficient of Thermal Expansion (CTE): CTE measures the degree to which a material expands or contracts with changes in temperature. A substrate material with a CTE close to that of the copper traces and components is desirable to minimize thermal stresses and improve reliability.

- Mechanical Strength: The substrate material should have sufficient mechanical strength to withstand the stresses encountered during manufacturing, assembly, and operation. It should resist warping, twisting, and bending to maintain the integrity of the PCB.

Common PCB Substrate Materials

There are several commonly used PCB substrate materials, each with its own set of properties and applications:

- FR-4: FR-4 is the most widely used PCB substrate material. It is a composite material made of woven fiberglass cloth impregnated with epoxy resin. FR-4 offers good mechanical strength, electrical insulation, and thermal stability. It is suitable for a wide range of applications, including consumer electronics, industrial control systems, and telecommunications equipment.

- High-Frequency Materials: For high-frequency applications, such as RF and microwave circuits, specialized substrate materials are used. These materials have low dielectric constants and dissipation factors to minimize signal loss and maintain signal integrity at high frequencies. Examples include Rogers RO4000 series, Teflon, and ceramic-based substrates like alumina and aluminum nitride.

- Flexible Substrates: Flexible PCBs require substrate materials that can withstand bending and flexing without compromising electrical performance. Polyimide and polyester films are commonly used for flexible PCBs due to their excellent mechanical flexibility, thermal stability, and electrical insulation properties.

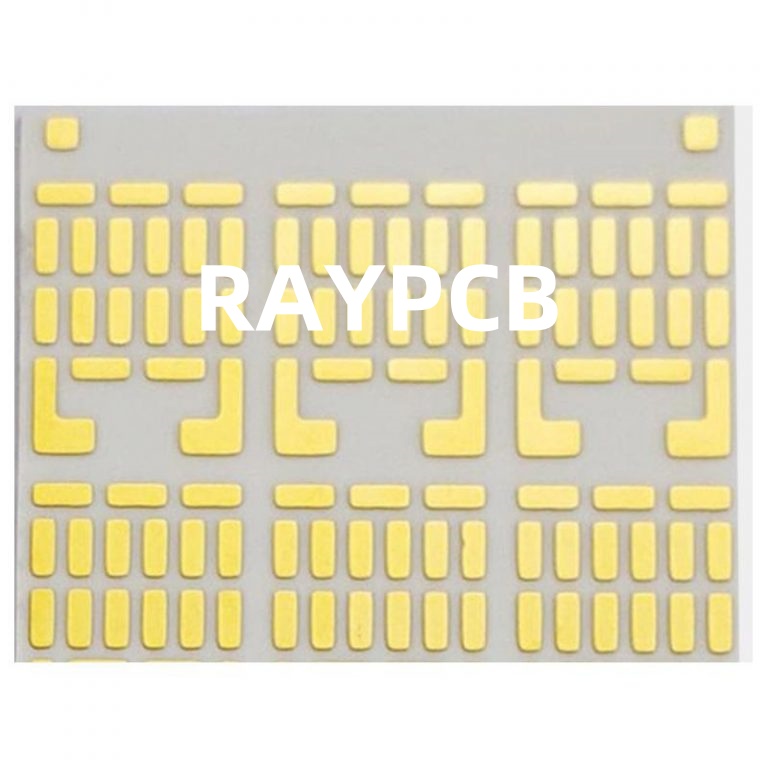

- Metal Core Substrates: For applications that generate significant heat, metal core substrates are used. These substrates have a metal core, typically aluminum, which acts as a heat spreader. The metal core is covered with a thin layer of dielectric material and copper foil for circuit patterning. Metal core substrates offer excellent thermal conductivity, helping to dissipate heat and improve the thermal management of the PCB.

- Ceramic Substrates: Ceramic substrates, such as alumina and beryllium oxide, are used in high-temperature and high-power applications. They have excellent thermal conductivity, high dielectric strength, and good mechanical stability. Ceramic substrates are often used in power electronics, aerospace, and military applications.

Factors Influencing PCB Substrate Selection

Choosing the right PCB substrate material involves considering various factors that impact the performance, reliability, and cost of the PCB:

- Frequency of Operation: The operating frequency of the circuit is a critical factor in substrate selection. For high-frequency applications, materials with low dielectric constants and dissipation factors are preferred to minimize signal loss and maintain signal integrity.

- Thermal Management: The thermal requirements of the application dictate the choice of substrate material. If the PCB is expected to generate significant heat, a substrate with high thermal conductivity, such as metal core or ceramic, is desirable to effectively dissipate heat and prevent thermal issues.

- Mechanical Requirements: The mechanical stresses that the PCB will encounter during manufacturing, assembly, and operation should be considered. The substrate material should have sufficient mechanical strength and stability to withstand these stresses and maintain the integrity of the PCB.

- Cost Considerations: The cost of the substrate material is an important factor, especially for high-volume production. FR-4 is a cost-effective option for general-purpose applications, while specialized materials like high-frequency laminates and ceramics come at a higher cost.

- Environmental Factors: The operating environment of the PCB should be taken into account. Factors such as temperature range, humidity, and exposure to chemicals or radiation can influence the choice of substrate material. Materials with high thermal stability, moisture resistance, and chemical inertness may be required for harsh environments.

- Manufacturing Process: The manufacturing process and the available fabrication capabilities can impact substrate selection. Some substrate materials may require specialized manufacturing techniques or have limitations in terms of minimum feature sizes or layer count.

PCB Substrate Material Comparison

To help compare and select the appropriate PCB substrate material, the following table provides an overview of the properties and typical applications of common substrate materials:

| Substrate Material | Dielectric Constant (Dk) | Dissipation Factor (Df) | Thermal Conductivity (W/mK) | Typical Applications |

|---|---|---|---|---|

| FR-4 | 4.2 – 4.5 | 0.02 – 0.03 | 0.3 – 0.4 | General-purpose, consumer electronics, industrial control |

| Rogers RO4000 | 3.3 – 3.5 | 0.0027 – 0.0037 | 0.6 – 0.7 | High-frequency, RF, microwave, telecommunications |

| Polyimide | 3.5 – 3.8 | 0.002 – 0.008 | 0.1 – 0.2 | Flexible PCBs, wearable electronics, aerospace |

| Aluminum (Metal Core) | 4.5 – 9.0 | 0.01 – 0.02 | 100 – 200 | Power electronics, LED lighting, automotive |

| Alumina (Ceramic) | 9.0 – 10.0 | 0.0001 – 0.0004 | 20 – 30 | High-temperature, high-power, aerospace, military |

PCB Substrate Material Selection Process

Selecting the appropriate PCB substrate material involves a systematic approach that takes into account the specific requirements of the application. Here are the steps involved in the selection process:

- Define Application Requirements: Start by clearly defining the requirements of your application, including the operating frequency, thermal management needs, mechanical constraints, environmental factors, and any specific performance criteria.

- Consider Electrical Properties: Evaluate the electrical properties of different substrate materials, particularly the dielectric constant (Dk) and dissipation factor (Df). Select materials that meet the requirements for signal integrity, low loss, and Impedance Control.

- Assess Thermal Management: Consider the thermal management requirements of your application. If heat dissipation is a critical factor, choose substrate materials with high thermal conductivity, such as metal core or ceramic substrates.

- Evaluate Mechanical Strength: Assess the mechanical strength and stability requirements of your PCB. Consider the expected stresses during manufacturing, assembly, and operation. Select materials that provide sufficient mechanical robustness and dimensional stability.

- Consider Manufacturing Constraints: Take into account the manufacturing constraints and capabilities of your PCB Fabrication partner. Some substrate materials may require specialized manufacturing processes or have limitations in terms of feature sizes or layer count.

- Evaluate Cost and Availability: Consider the cost implications of different substrate materials, especially for high-volume production. Assess the availability and lead times of the selected materials to ensure a reliable supply chain.

- Prototype and Test: Once you have narrowed down the potential substrate materials, create prototypes and conduct thorough testing to validate the performance, reliability, and manufacturability of the PCB.

- Collaborate with Experts: Engage with PCB Design and manufacturing experts who can provide valuable insights and recommendations based on their experience and knowledge of different substrate materials and applications.

Frequently Asked Questions (FAQ)

- What is the most commonly used PCB substrate material?

FR-4 is the most widely used PCB substrate material due to its good balance of electrical, mechanical, and thermal properties, as well as its cost-effectiveness. - What substrate materials are suitable for high-frequency applications?

For high-frequency applications, substrate materials with low dielectric constants and dissipation factors are preferred. Examples include Rogers RO4000 series, Teflon, and ceramic-based substrates like alumina and aluminum nitride. - How does the thermal conductivity of a substrate material affect PCB performance?

A substrate material with high thermal conductivity helps in dissipating heat generated by electronic components, preventing thermal stress and ensuring better performance. It is particularly important for applications that generate significant heat, such as power electronics and LED lighting. - What are flexible PCB substrate materials?

Flexible PCB substrate materials are designed to withstand bending and flexing without compromising electrical performance. Common flexible substrate materials include polyimide and polyester films, which offer excellent mechanical flexibility, thermal stability, and electrical insulation properties. - How do I choose the right PCB substrate material for my application?

Choosing the right PCB substrate material involves considering various factors, including the operating frequency, thermal management requirements, mechanical constraints, environmental factors, cost, and manufacturing capabilities. It is recommended to collaborate with PCB design and manufacturing experts who can provide guidance based on your specific application requirements.

Conclusion

PCB substrate material selection is a critical aspect of PCB design and manufacturing. The choice of substrate material directly impacts the electrical, thermal, and mechanical performance of the PCB, as well as its reliability and functionality. By understanding the properties, types, and applications of different substrate materials, designers can make informed decisions to optimize their PCB designs.

When selecting a PCB substrate material, it is essential to consider factors such as the operating frequency, thermal management requirements, mechanical constraints, environmental factors, cost, and manufacturing capabilities. A systematic approach that involves defining application requirements, evaluating material properties, and collaborating with experts can help in making the right substrate material choice.

As technology advances and new applications emerge, the development of advanced substrate materials continues to evolve. Innovations in material science and manufacturing techniques are enabling the creation of substrates with enhanced properties, such as improved thermal conductivity, lower dielectric constants, and better mechanical stability. These advancements are driving the development of high-performance PCBs for cutting-edge applications in industries such as telecommunications, aerospace, automotive, and consumer electronics.

In conclusion, understanding and selecting the appropriate PCB substrate material is crucial for designing reliable, high-performance electronic circuits. By considering the specific requirements of the application and leveraging the expertise of PCB design and manufacturing professionals, engineers can make informed decisions that optimize the performance, reliability, and cost-effectiveness of their PCB designs.

No responses yet