What is OSP?

OSP is a thin, transparent organic coating applied to the copper pads on a PCB. The main purpose of OSP is to protect the copper from oxidation and maintain its solderability during storage and assembly. OSP is composed of organic compounds, typically benzimidazoles or benzotriazoles, which form a strong bond with the copper surface and prevent it from reacting with the atmosphere.

How is OSP applied?

The OSP application process involves the following steps:

- Cleaning: The PCB is thoroughly cleaned to remove any contaminants or residues from the copper surface.

- Microetching: A mild etching solution is used to remove the oxide layer and activate the copper surface.

- OSP application: The PCB is immersed in an OSP solution, allowing the organic compounds to form a protective layer on the copper pads.

- Drying: The PCB is dried using hot air or infrared lamps to evaporate any remaining solvents and ensure a uniform coating.

Advantages of OSP

Cost-effectiveness

One of the primary advantages of OSP is its cost-effectiveness compared to other Surface Finishes. The materials and equipment used in the OSP process are relatively inexpensive, making it an attractive option for high-volume production.

| Surface Finish | Relative Cost |

|---|---|

| OSP | Low |

| HASL | Medium |

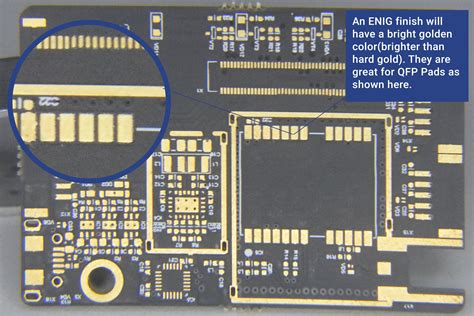

| ENIG | High |

| Immersion Silver | Medium-High |

Environmental friendliness

OSP is considered an environmentally friendly surface finish as it does not contain any hazardous materials like lead or nickel. The organic compounds used in OSP are biodegradable and do not pose a significant threat to the environment.

Good solderability

OSP provides excellent solderability, ensuring a strong and reliable bond between the PCB and the electronic components. The organic coating prevents oxidation and maintains the wettability of the copper surface, allowing for easy and consistent soldering.

Flat surface

Unlike HASL, which can result in uneven surfaces due to the hot air leveling process, OSP provides a flat and uniform surface. This flatness is essential for fine-pitch components and high-density PCB Designs, as it ensures proper placement and reduces the risk of bridging or tombstoning.

Disadvantages of OSP

Limited shelf life

One of the main drawbacks of OSP is its limited shelf life. The organic coating is susceptible to degradation over time, especially when exposed to high temperatures and humidity. As a result, OSP-coated PCBs typically have a shelf life of 6 to 12 months, after which the solderability may deteriorate.

Sensitivity to handling

OSP-coated PCBs are sensitive to handling and require extra care during storage and assembly. The organic coating can be easily contaminated by skin oils, dirt, or other substances, which can affect its solderability. Proper handling procedures, such as using gloves and clean environments, are crucial to maintain the integrity of the OSP finish.

Not suitable for multiple reflow cycles

OSP is not recommended for PCBs that require multiple reflow cycles, such as double-sided assemblies or rework processes. The organic coating can degrade during the first reflow cycle, leaving the copper surface exposed and prone to oxidation during subsequent reflow cycles. In such cases, other surface finishes like ENIG or Immersion Silver may be more appropriate.

Applications of OSP-PCB

OSP-PCBs are widely used in various industries and applications, including:

- Consumer electronics

- Automotive electronics

- Telecommunications

- Industrial control systems

- Medical devices

OSP is particularly suitable for applications that require cost-effectiveness, environmental friendliness, and good solderability. However, it may not be the best choice for high-reliability applications or those that involve extensive storage or multiple reflow cycles.

Frequently Asked Questions (FAQ)

1. How long does OSP last on a PCB?

OSP-coated PCBs typically have a shelf life of 6 to 12 months, depending on the storage conditions and the specific OSP formulation used. Proper storage in a cool, dry environment can help extend the shelf life.

2. Can OSP be used for Lead-Free Soldering?

Yes, OSP is compatible with lead-free soldering processes. The organic coating provides good solderability and wettability for lead-free solders, ensuring a reliable and strong bond between the PCB and the components.

3. Is OSP better than HASL?

The choice between OSP and HASL depends on the specific requirements of the application. OSP offers advantages such as cost-effectiveness, environmental friendliness, and a flat surface, while HASL provides better durability and resistance to multiple reflow cycles. The decision should be based on factors such as the PCB design, Component Types, and reliability requirements.

4. Can OSP be reworked?

Reworking OSP-coated PCBs can be challenging, as the organic coating may have degraded during the initial soldering process. If rework is necessary, it is recommended to remove the old OSP coating and reapply a fresh layer before soldering the new components.

5. How can I test the solderability of an OSP-coated PCB?

The solderability of an OSP-coated PCB can be tested using various methods, such as the wetting balance test, the dip and look test, or the surface insulation resistance (SIR) test. These tests evaluate the wettability, spreading, and bonding strength of the solder on the OSP surface.

Conclusion

OSP is a popular and cost-effective surface finish for PCBs, offering good solderability, environmental friendliness, and a flat surface. However, it also has limitations, such as a limited shelf life and sensitivity to handling. When deciding whether to use OSP for a specific application, it is essential to consider the trade-offs and evaluate the specific requirements of the project.

By understanding the properties, advantages, and disadvantages of OSP-PCB, engineers and manufacturers can make informed decisions and optimize their PCB designs for cost, reliability, and performance.

No responses yet