Introduction to HDI PCBs

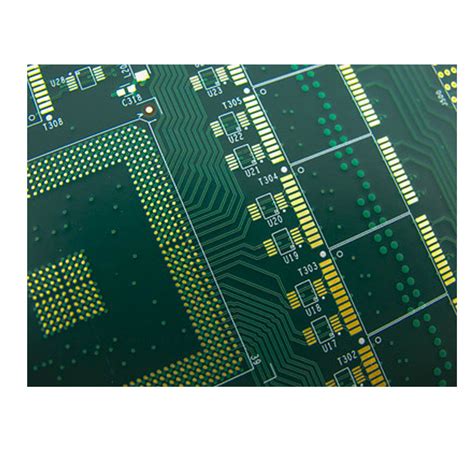

HDI PCBs, which stands for High Density Interconnect Printed Circuit Boards, are an advanced type of PCB that enables the miniaturization of electronic devices. As technology progresses and consumer demand for smaller, lighter, and more powerful gadgets increases, HDI PCBs have become an essential component in many industries such as telecommunications, aerospace, medical devices, and consumer electronics.

HDI PCBs differ from conventional PCBs in several ways. They have finer traces and spaces, smaller vias, and higher layer counts, allowing for greater circuit density and functionality in a smaller footprint. This article will delve into the structure, manufacturing process, advantages, and applications of HDI PCBs.

What Makes a PCB an HDI PCB?

According to the IPC (Association Connecting Electronics Industries), a PCB is considered an HDI PCB if it meets the following criteria:

| HDI Attribute | Requirement |

|---|---|

| Line Width/Space | ≤ 100 µm |

| Capture Pad | ≤ 400 µm |

| Micro Via Diameter | ≤ 150 µm |

| Via Pad Diameter | ≤ 350 µm |

| Via Pitch | ≤ 800 µm |

These stringent requirements enable HDI PCBs to pack more components and interconnections into a smaller area compared to traditional PCBs.

Structure of HDI PCBs

Substrate Materials

The base material, or substrate, of an HDI PCB is typically made from a glass-reinforced epoxy laminate, such as FR-4. However, for high-frequency or high-speed applications, low-loss materials like Rogers or Isola may be used to minimize signal loss and maintain signal integrity.

Copper Foil

HDI PCBs use thin copper foils, usually 1/2 oz or 1/3 oz (17 µm or 12 µm thick), to achieve finer trace widths and spaces. The thinner copper allows for tighter tolerances and higher circuit density.

Micro Vias

One of the defining features of HDI PCBs is the use of micro vias, which are small holes drilled through one or more layers to interconnect the layers. Micro vias have a diameter of 150 µm or less and can be formed using various methods, such as laser drilling, photovia, or conductive paste.

Micro vias enable shorter interconnections between layers, reducing signal path length and improving electrical performance. They also allow for higher routing density and more efficient use of board space.

Buildup Layers

HDI PCBs often employ a sequential buildup process, where additional layers are added one at a time to the base substrate. This process allows for the creation of fine-pitch structures and enables the embedding of passive components, such as resistors and capacitors, within the PCB.

The number of buildup layers in an HDI PCB can vary depending on the complexity and requirements of the design. Some HDI PCBs may have just a few layers, while others can have 12 or more.

Manufacturing Process of HDI PCBs

The manufacturing process of HDI PCBs is more complex and precise than that of conventional PCBs. It involves several key steps:

1. Design and Layout

The first step in manufacturing an HDI PCB is to create the design and layout using Electronic Design Automation (EDA) software. The designer must adhere to the strict design rules and constraints specific to HDI PCBs, such as minimum trace width and spacing, via size and pitch, and layer stackup.

2. Material Selection and Preparation

Once the design is finalized, the appropriate substrate material and copper foil are selected based on the PCB’s requirements. The substrate is cut to size, and the copper foil is laminated onto the substrate using heat and pressure.

3. Drilling and Via Formation

Next, holes are drilled through the PCB to create interconnections between layers. For HDI PCBs, this often involves laser drilling to create micro vias. Other methods, such as photovia or conductive paste, may also be used depending on the design and manufacturing capabilities.

4. Patterning and Etching

The desired circuit pattern is then transferred onto the copper layers using a photolithography process. A photoresist is applied to the copper, exposed to UV light through a photomask, and developed to create the circuit pattern. The exposed copper is then etched away using a chemical solution, leaving only the desired traces and pads.

5. Lamination and Buildup

For multi-layer HDI PCBs, the patterned layers are laminated together using heat and pressure. Additional buildup layers may be added sequentially, with micro vias connecting the layers as needed.

6. Surface Finish and Solder Mask

A surface finish, such as ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling), is applied to the exposed copper to protect it from oxidation and improve solderability. A solder mask is also applied to the PCB to insulate and protect the traces, leaving only the pads exposed for component assembly.

7. Electrical Testing and Inspection

Finally, the manufactured HDI PCB undergoes rigorous electrical testing and visual inspection to ensure that it meets the required specifications and quality standards. This may include flying probe testing, automated optical inspection (AOI), and X-ray inspection for hidden defects.

Advantages of HDI PCBs

HDI PCBs offer several advantages over conventional PCBs:

-

Miniaturization: The higher circuit density and finer features of HDI PCBs enable the creation of smaller, lighter, and more compact electronic devices.

-

Improved Electrical Performance: The shorter interconnections and reduced signal path length in HDI PCBs result in better signal integrity, lower inductance and capacitance, and reduced electromagnetic interference (EMI).

-

Increased Functionality: With the ability to pack more components and circuits into a smaller area, HDI PCBs can provide more functionality and features in a given footprint.

-

Cost Reduction: Although the manufacturing process of HDI PCBs is more complex and costly compared to conventional PCBs, the overall cost of the end product can be reduced due to the smaller size and fewer components required.

-

Reliability: HDI PCBs are known for their high reliability due to the use of advanced manufacturing processes and materials, as well as the reduced number of interconnections and solder joints.

Applications of HDI PCBs

HDI PCBs find applications in various industries and products that require high performance, small size, and reliability. Some examples include:

- Smartphones and tablets

- Wearable devices

- Medical implants and devices

- Aerospace and defense electronics

- Automotive electronics

- High-speed networking equipment

- Internet of Things (IoT) devices

As technology continues to advance and the demand for smaller, smarter, and more connected devices grows, the use of HDI PCBs is expected to increase in the coming years.

FAQ

1. What is the difference between HDI PCBs and conventional PCBs?

HDI PCBs have finer traces and spaces, smaller vias, and higher layer counts compared to conventional PCBs. This allows for greater circuit density and functionality in a smaller footprint.

2. What are micro vias, and why are they important in HDI PCBs?

Micro vias are small holes drilled through one or more layers to interconnect the layers in an HDI PCB. They have a diameter of 150 µm or less and enable shorter interconnections between layers, reducing signal path length and improving electrical performance.

3. What materials are used in HDI PCBs?

HDI PCBs typically use a glass-reinforced epoxy laminate, such as FR-4, as the base substrate. For high-frequency or high-speed applications, low-loss materials like Rogers or Isola may be used. Thin copper foils, usually 1/2 oz or 1/3 oz, are used to achieve finer trace widths and spaces.

4. How are HDI PCBs manufactured?

The manufacturing process of HDI PCBs involves several key steps, including design and layout, material selection and preparation, drilling and via formation, patterning and etching, lamination and buildup, surface finish and solder mask application, and electrical testing and inspection.

5. What are the advantages of using HDI PCBs?

HDI PCBs offer several advantages, including miniaturization, improved electrical performance, increased functionality, cost reduction, and high reliability. These benefits make HDI PCBs suitable for a wide range of applications in various industries.

Conclusion

HDI PCBs are a critical component in the advancement of electronic devices, enabling the creation of smaller, faster, and more functional products. By understanding the structure, manufacturing process, advantages, and applications of HDI PCBs, engineers and designers can leverage this technology to develop innovative solutions that meet the ever-increasing demands of the market.

As the electronics industry continues to evolve, HDI PCBs will play an increasingly important role in shaping the future of technology. With their ability to pack more functionality into smaller spaces, HDI PCBs will be at the forefront of the next generation of electronic devices, from wearables and IoT devices to advanced medical equipment and aerospace systems.

No responses yet