Understanding the Production-Prototype Gap

In the world of product development, there is often a significant difference between the quality of a prototype and the quality of a production-ready product. This gap, known as the Production-Prototype Gap, can be a major challenge for companies looking to bring new products to market quickly and efficiently. In this article, we will explore the key differences between production and prototype quality, and discuss strategies for bridging the gap between the two.

What is a Prototype?

A prototype is an early version of a product that is used to test and validate design concepts, functionality, and user experience. Prototypes can range from simple sketches and mockups to fully functional models that closely resemble the final product. The main purpose of a prototype is to gather feedback from stakeholders and users, and to identify any issues or improvements that need to be made before the product goes into full-scale production.

What is Production Quality?

Production quality refers to the level of quality that is required for a product to be suitable for mass production and distribution to customers. Production quality products must meet strict standards for reliability, durability, and consistency, and must be able to withstand the rigors of everyday use. Achieving production quality requires a significant investment in time, resources, and expertise, and often involves multiple rounds of testing and refinement.

Key Differences between Production and Prototype Quality

There are several key differences between production and prototype quality that can contribute to the Production-Prototype Gap. These include:

Materials and Components

Prototypes are often made using lower-cost materials and components that may not be suitable for production. For example, a prototype may use 3D-printed parts or off-the-shelf components that are readily available, while a production product may require custom-designed parts made from high-quality materials.

Manufacturing Processes

The manufacturing processes used to create prototypes are often different from those used in production. Prototypes may be made using manual or semi-automated processes, while production products are typically made using automated, high-volume manufacturing techniques.

Tolerances and Specifications

Production products must meet tight tolerances and specifications to ensure consistency and reliability. Prototypes, on the other hand, may have looser tolerances and may not be held to the same strict standards.

Testing and Validation

Production products undergo rigorous testing and validation to ensure that they meet all necessary standards and regulations. Prototypes may undergo some testing, but the level of validation is often much lower than what is required for production.

Strategies for Bridging the Production-Prototype Gap

Bridging the Production-Prototype Gap requires a strategic approach that involves collaboration between design, engineering, and manufacturing teams. Some key strategies for bridging the gap include:

Design for Manufacturability (DFM)

DFM is a process that involves designing products with production in mind from the outset. This means considering factors such as material selection, manufacturing processes, and assembly methods early in the design process to ensure that the product can be efficiently and cost-effectively produced at scale.

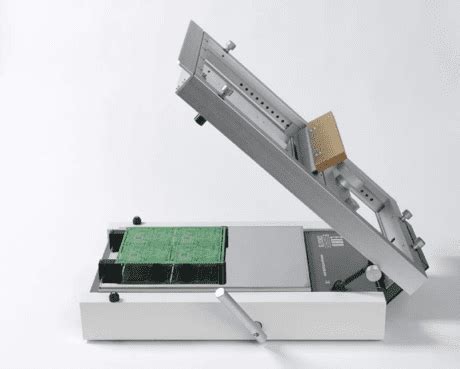

Rapid Prototyping

Rapid prototyping techniques such as 3D printing and CNC Machining can help bridge the gap between prototype and production by allowing for quick iterations and design changes. These techniques can also be used to create functional prototypes that more closely resemble the final product.

Pilot Production Runs

Pilot production runs involve producing a small batch of products using production-grade materials and processes. This allows for testing and validation of the manufacturing process, and can help identify any issues or bottlenecks before full-scale production begins.

Collaboration and Communication

Effective collaboration and communication between design, engineering, and manufacturing teams is critical for bridging the Production-Prototype Gap. Regular meetings, design reviews, and feedback sessions can help ensure that everyone is on the same page and working towards the same goals.

Case Studies

To illustrate the challenges and strategies involved in bridging the Production-Prototype Gap, let’s look at a few real-world examples.

Apple’s iPhone

When Apple first introduced the iPhone in 2007, it was a revolutionary product that set a new standard for smartphones. However, bringing the iPhone to market required overcoming significant production challenges. One key challenge was the use of a glass screen, which was prone to cracking and shattering. To address this issue, Apple worked closely with its manufacturing partners to develop a custom glass that was stronger and more durable than traditional glass. They also invested heavily in automated manufacturing processes to ensure consistent quality and high volumes.

| Component | Prototype | Production |

|---|---|---|

| Screen | Standard glass | Custom-developed glass |

| Manufacturing | Manual assembly | Automated assembly lines |

| Volumes | Small batches | Millions of units per year |

Tesla’s Model 3

Tesla’s Model 3 was another product that faced significant production challenges. When the car was first announced, Tesla promised to deliver hundreds of thousands of units per year at a starting price of $35,000. However, ramping up production proved to be much more difficult than anticipated. One key issue was the use of a highly automated production line, which was prone to bottlenecks and quality issues. To address these challenges, Tesla had to make significant changes to its manufacturing process, including adding more manual assembly steps and reducing the level of automation.

| Aspect | Prototype | Production |

|---|---|---|

| Volumes | Dozens of units | Thousands of units per week |

| Automation | Highly automated | Mix of automated and manual processes |

| Quality | Inconsistent | Improved, but still facing challenges |

Frequently Asked Questions

How long does it typically take to go from prototype to production?

The timeline for going from prototype to production can vary widely depending on the complexity of the product and the resources available. In general, it can take anywhere from several months to several years to fully bridge the Production-Prototype Gap.

What are some common mistakes companies make when trying to bridge the gap?

Some common mistakes include:

– Underestimating the complexity and cost of production

– Failing to involve manufacturing teams early in the design process

– Relying too heavily on automation without proper testing and validation

– Not allowing enough time for testing and refinement

How can I ensure that my product meets all necessary standards and regulations?

Ensuring that your product meets all necessary standards and regulations requires a comprehensive testing and validation process. This may include:

– Conducting safety and performance testing

– Obtaining necessary certifications and approvals

– Conducting user testing and gathering feedback

– Developing detailed product specifications and documentation

What are some key considerations when selecting materials for production?

When selecting materials for production, some key considerations include:

– Cost and availability

– Durability and reliability

– Compatibility with manufacturing processes

– Environmental impact and sustainability

– Regulatory requirements and standards

How can I balance the need for quick iterations with the need for production-grade quality?

Balancing the need for quick iterations with the need for production-grade quality requires a strategic approach that involves:

– Using rapid prototyping techniques to quickly test and validate designs

– Involving manufacturing teams early in the design process to ensure manufacturability

– Conducting pilot production runs to test and refine the manufacturing process

– Collaborating closely between design, engineering, and manufacturing teams to ensure alignment and communication

Conclusion

Bridging the Production-Prototype Gap is a critical challenge for companies looking to bring new products to market quickly and efficiently. By understanding the key differences between production and prototype quality, and by implementing strategies such as DFM, rapid prototyping, pilot production runs, and effective collaboration and communication, companies can successfully bridge the gap and deliver high-quality products to their customers.

No responses yet