Introduction to SMT Ordering

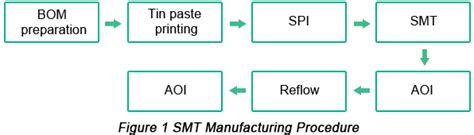

Surface Mount Technology (SMT) ordering is a crucial process in the electronics manufacturing industry. It involves procuring the necessary components and materials required for assembling printed circuit boards (PCBs) using SMT. Accurate and efficient SMT ordering is essential for ensuring smooth production, minimizing delays, and maintaining product quality.

In this article, we will discuss the necessary files and information required for accurate SMT ordering, which in turn supports efficient quote and manufacturing processes.

Key Components of SMT Ordering

Bill of Materials (BOM)

The Bill of Materials (BOM) is a comprehensive list of all the components and materials needed to manufacture a PCB. It includes details such as part numbers, quantities, descriptions, and manufacturers. An accurate BOM is the foundation of successful SMT ordering.

A typical BOM should include the following information:

| Column Name | Description |

|---|---|

| Item No. | Unique identifier for each component |

| Part Number | Manufacturer’s part number |

| Description | Brief description of the component |

| Quantity | Number of components required |

| Manufacturer | Name of the component manufacturer |

| Reference Designator | Location of the component on the PCB |

Gerber Files

Gerber files are the industry standard for representing PCB designs. They contain the necessary information for manufacturing the PCB, including copper layers, solder mask, silkscreen, and drill data. Gerber files are essential for accurately communicating the PCB design to the manufacturing team.

The most common Gerber file extensions include:

- .GTL (Top Layer)

- .GBL (Bottom Layer)

- .GTO (Top Overlay)

- .GBO (Bottom Overlay)

- .GTP (Top Paste Mask)

- .GBP (Bottom Paste Mask)

- .GTS (Top Solder Mask)

- .GBS (Bottom Solder Mask)

- .TXT or .DRL (Drill Data)

Pick and Place Files

Pick and Place (PnP) files provide the necessary information for automated component placement on the PCB. They contain the coordinates, rotations, and part numbers of each component. PnP files ensure accurate and efficient component placement during the SMT Assembly process.

A standard PnP file should include the following data:

| Column Name | Description |

|---|---|

| Ref Des | Reference designator of the component |

| Part Number | Manufacturer’s part number |

| X Coord | X-coordinate of the component placement |

| Y Coord | Y-coordinate of the component placement |

| Rotation | Rotation angle of the component |

| Side | PCB side (Top or Bottom) |

Centroid Data

Centroid data files provide the center points of each component on the PCB. They are used in conjunction with the PnP files to ensure precise component placement. Centroid data is typically generated from the PCB design software and is essential for programming the pick and place machine.

Assembly Drawings

Assembly drawings provide a visual representation of the PCB Assembly, including component placement, orientation, and any special instructions. They serve as a reference for the manufacturing team and help ensure accurate assembly.

Assembly drawings should include:

- PCB dimensions and mounting holes

- Component locations and orientations

- Special assembly instructions (e.g., hand soldering, conformal coating)

- Revision history and notes

Importance of Accurate Information in SMT Ordering

Accurate information is crucial for successful SMT ordering and manufacturing. Inaccurate or incomplete data can lead to several issues, including:

- Incorrect component procurement

- Delays in production

- Increased costs due to rework or scrap

- Reduced product quality and reliability

To ensure accurate information, consider the following best practices:

Verify BOM Data

- Cross-check part numbers and descriptions with manufacturer Datasheets

- Confirm quantities and reference designators

- Verify obsolescence status and availability of components

Review Gerber Files

- Ensure all necessary layers are included

- Check for any design rule violations or inconsistencies

- Verify the accuracy of drill data

Validate PnP and Centroid Data

- Compare PnP and centroid data with the BOM and assembly drawings

- Verify Component orientations and placement coordinates

- Ensure compatibility with the pick and place machine

Maintain Clear Communication

- Provide clear instructions and notes to the manufacturing team

- Respond promptly to any queries or clarifications

- Establish a robust revision control system

Supporting Efficient Quote and Manufacturing Processes

Accurate SMT ordering information not only ensures successful manufacturing but also supports efficient quote processes. When requesting quotes from SMT assembly providers, having complete and accurate data helps streamline the process and ensures precise cost estimations.

To support efficient quote and manufacturing processes:

- Provide a complete and accurate BOM

- Include all necessary Gerber, PnP, and centroid files

- Specify any special requirements or instructions

- Communicate the expected production volume and timeline

- Maintain open communication with the SMT assembly provider

By providing comprehensive and accurate information upfront, you enable the SMT assembly provider to generate accurate quotes quickly and efficiently plan the manufacturing process.

Conclusion

SMT ordering is a critical aspect of electronics manufacturing that requires accurate information and attention to detail. By ensuring the accuracy and completeness of necessary files such as the BOM, Gerber files, PnP data, and assembly drawings, you can support efficient quote processes and streamline manufacturing.

Implementing best practices for verifying data, maintaining clear communication, and collaborating closely with SMT assembly providers will help minimize delays, reduce costs, and ensure high-quality products. Investing time and effort into accurate SMT ordering pays off in the long run, leading to successful and efficient electronics manufacturing.

Frequently Asked Questions (FAQ)

-

What is the difference between a BOM and a PnP file?

A Bill of Materials (BOM) is a comprehensive list of all components and materials required for PCB assembly, while a Pick and Place (PnP) file provides the specific placement coordinates and orientations of each component on the PCB. -

Why are Gerber files important in SMT ordering?

Gerber files are the industry standard for representing PCB designs. They contain essential information for manufacturing the PCB, including copper layers, solder mask, silkscreen, and drill data. Accurate Gerber files ensure the PCB is manufactured according to the specified design. -

What happens if the SMT ordering information is inaccurate?

Inaccurate SMT ordering information can lead to several issues, such as incorrect component procurement, production delays, increased costs due to rework or scrap, and reduced product quality. It is crucial to ensure the accuracy of all necessary files and data before submitting an SMT order. -

How can I ensure the accuracy of my SMT ordering information?

To ensure accuracy, verify the BOM data against manufacturer datasheets, review Gerber files for any inconsistencies or design rule violations, validate PnP and centroid data against the BOM and assembly drawings, and maintain clear communication with the manufacturing team. -

What information should I provide when requesting a quote from an SMT assembly provider?

When requesting a quote, provide a complete and accurate BOM, all necessary Gerber, PnP, and centroid files, any special requirements or instructions, the expected production volume, and timeline. This information helps the SMT assembly provider generate an accurate quote and efficiently plan the manufacturing process.

No responses yet