Introduction to PCB Registration

Printed Circuit Board (PCB) registration is a crucial process in the manufacturing of electronic devices. It ensures that the various layers of a PCB align precisely with each other, resulting in a functional and reliable product. PCB registration is also essential for the proper placement of components on the board, as well as for the application of solder paste using stencils.

In this article, we will delve into the details of PCB registration systems, focusing on the methods used for both PCBs and stencils. We will also discuss the importance of accurate registration, common challenges faced during the process, and best practices for achieving optimal results.

PCB Registration Methods

There are several methods used for PCB registration, each with its own advantages and limitations. Let’s explore some of the most common techniques:

1. Fiducial Marks

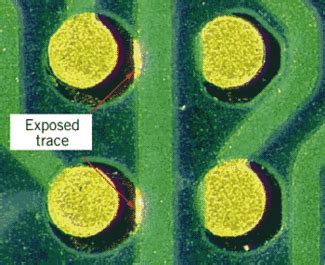

Fiducial marks are small, precisely placed features on a PCB that serve as reference points for alignment. These marks are typically copper pads or solder mask openings that are easily recognizable by machine vision systems. The placement of fiducial marks is critical, as they must be visible on all layers of the PCB to ensure accurate registration.

| Fiducial Mark Type | Description |

|---|---|

| Global Fiducials | Used for aligning the entire PCB |

| Local Fiducials | Used for aligning specific components or areas on the PCB |

| Panel Fiducials | Used for aligning multiple PCBs on a larger panel |

2. Pin Registration

Pin registration involves the use of precisely located holes or slots on the PCB that correspond to pins on the manufacturing equipment. These pins help to physically align the PCB during the various stages of production, such as drilling, solder paste application, and component placement.

Pin registration is often used in conjunction with fiducial marks to achieve the highest level of accuracy. However, it is important to note that pin registration requires additional design considerations and may not be suitable for all PCB designs.

3. Edge Registration

Edge registration relies on the precise machining of the PCB’s edges to align it with the manufacturing equipment. This method is often used for smaller PCBs or those with limited space for fiducial marks or pin registration.

To ensure accurate edge registration, the PCB design must include clear and well-defined edges that can be easily located by the manufacturing equipment. Additionally, proper handling and storage of the PCBs are essential to prevent damage to the edges, which could compromise the registration process.

Stencil Registration Methods

Stencil registration is equally important for ensuring accurate solder paste application on PCBs. There are two primary methods used for stencil registration:

1. Frame Mounting

Frame mounting involves attaching the stencil to a rigid frame that is precisely aligned with the PCB. The frame is typically made of stainless steel and includes pins or other features that correspond to the registration marks on the PCB.

| Advantage | Disadvantage |

|---|---|

| Provides a stable and repeatable setup | Requires additional equipment and setup time |

| Suitable for high-volume production | May not be cost-effective for low-volume or prototype runs |

2. Frameless Mounting

Frameless mounting, also known as direct mounting, involves placing the stencil directly onto the PCB without the use of a frame. This method relies on the precise alignment of the stencil’s apertures with the PCB’s pads and the use of a vacuum or other means to hold the stencil in place during solder paste application.

| Advantage | Disadvantage |

|---|---|

| Faster setup time compared to frame mounting | Requires precise stencil design and fabrication |

| More cost-effective for low-volume or prototype runs | May not be as stable as frame mounting for high-volume production |

Importance of Accurate PCB and Stencil Registration

Accurate PCB and stencil registration is essential for several reasons:

- Functionality: Proper alignment of the PCB Layers and components ensures that the final product functions as intended. Misalignment can lead to shorts, opens, or other defects that can compromise the device’s performance.

- Reliability: Accurate registration helps to minimize stress on components and solder joints, improving the overall reliability of the PCB.

- Manufacturing Efficiency: Precise registration enables faster and more automated manufacturing processes, reducing the need for manual intervention and minimizing the risk of human error.

- Cost Reduction: By minimizing defects and improving manufacturing efficiency, accurate registration can help to reduce overall production costs.

Common Challenges in PCB and Stencil Registration

Despite the importance of accurate registration, there are several challenges that can arise during the process:

- Design Limitations: PCB designs with limited space or complex geometries may make it difficult to incorporate registration marks or pins.

- Material Instability: Changes in temperature or humidity can cause PCB materials to expand or contract, affecting the accuracy of registration.

- Equipment Limitations: Older or poorly maintained manufacturing equipment may not have the precision necessary for accurate registration.

- Human Error: Improper handling, storage, or setup of PCBs and stencils can lead to registration errors.

Best Practices for PCB and Stencil Registration

To ensure accurate and reliable PCB and stencil registration, consider the following best practices:

- Incorporate registration marks early in the design process: Work with your PCB designer to include appropriate fiducial marks or pin registration features from the beginning.

- Use high-quality materials: Choose PCB and stencil materials that are dimensionally stable and resistant to environmental factors.

- Invest in modern, well-maintained equipment: Ensure that your manufacturing equipment is capable of achieving the necessary precision for accurate registration.

- Implement robust quality control processes: Regularly inspect and verify the accuracy of registration throughout the manufacturing process.

- Provide clear instructions and training: Ensure that all personnel involved in PCB and stencil handling are properly trained and equipped with the necessary tools and information.

FAQ

- What is the most common method for PCB registration?

The most common method for PCB registration is the use of fiducial marks, which serve as reference points for aligning the various layers and components of the PCB. - Can PCB registration be achieved without the use of fiducial marks?

Yes, alternative methods such as pin registration and edge registration can be used for PCB alignment, although fiducial marks are often preferred for their versatility and compatibility with a wide range of PCB designs. - What are the key differences between frame and frameless stencil mounting?

Frame mounting involves attaching the stencil to a rigid frame that is aligned with the PCB, while frameless mounting places the stencil directly onto the PCB. Frame mounting provides a more stable setup but requires additional equipment and setup time, while frameless mounting is faster and more cost-effective for low-volume production. - How can I ensure accurate PCB and stencil registration in my manufacturing process?

To ensure accurate registration, incorporate appropriate registration marks or features early in the PCB design process, use high-quality materials, invest in modern and well-maintained equipment, implement robust quality control processes, and provide clear instructions and training to all personnel involved in PCB and stencil handling. - What are the consequences of poor PCB and stencil registration?

Poor registration can lead to a variety of issues, including component misalignment, solder paste application defects, and compromised device functionality and reliability. These issues can result in increased production costs, delayed time-to-market, and potential product failures in the field.

Conclusion

PCB and stencil registration is a critical aspect of electronic device manufacturing, ensuring the proper alignment of layers, components, and solder paste application. By understanding the various registration methods, common challenges, and best practices, manufacturers can optimize their processes to achieve high-quality, reliable, and cost-effective products.

As PCB designs continue to become more complex and compact, the importance of accurate registration will only continue to grow. By staying up-to-date with the latest technologies and techniques, and by fostering a culture of continuous improvement, manufacturers can position themselves for success in this rapidly evolving industry.

No responses yet