Introduction to PCB Plating Simulation

Printed Circuit Board (PCB) design is a complex process that involves multiple steps, from schematic design to component placement, routing, and finally, manufacturing. One critical aspect of PCB manufacturing is the plating process, which involves depositing a layer of metal onto the PCB surface to create electrical connections and protect the board from corrosion. Traditionally, PCB designers have relied on their experience and knowledge of plating processes to ensure that their designs are manufacturable and reliable. However, with the increasing complexity of PCB designs and the demand for faster time-to-market, designers need more advanced tools to optimize their designs for plating.

This is where PCB plating simulation comes in. PCB plating simulation is a powerful tool that allows designers to simulate the plating process virtually, before the board is manufactured. By using plating simulation, designers can identify potential issues with their designs, such as uneven plating thickness, voids, or other defects that could affect the performance and reliability of the PCB. In this article, we will explore the benefits of PCB plating simulation, how it works, and how it can help PCB designers create better, more reliable designs.

Benefits of PCB Plating Simulation

1. Improved Design Quality

One of the primary benefits of PCB plating simulation is that it allows designers to improve the quality of their designs. By simulating the plating process, designers can identify potential issues with their designs before the board is manufactured. This means that designers can make adjustments to their designs to optimize them for plating, resulting in higher quality PCBs with fewer defects.

2. Reduced Manufacturing Costs

Another benefit of PCB plating simulation is that it can help reduce manufacturing costs. By identifying potential issues with the design before manufacturing, designers can avoid costly rework or scrap. Additionally, by optimizing the design for plating, designers can reduce the amount of material needed for plating, which can result in significant cost savings.

3. Faster Time-to-Market

PCB plating simulation can also help reduce the time-to-market for PCB designs. By identifying potential issues early in the design process, designers can avoid delays caused by rework or redesign. Additionally, by optimizing the design for plating, designers can reduce the time needed for the plating process itself, which can help speed up the overall manufacturing process.

How PCB Plating Simulation Works

PCB plating simulation works by using advanced algorithms to model the plating process virtually. The simulation takes into account a variety of factors, including the geometry of the PCB, the materials used, and the plating parameters, such as current density, time, and temperature.

The simulation process typically involves the following steps:

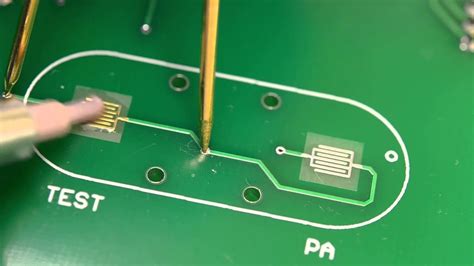

- CAD Model Creation: The first step in PCB plating simulation is to create a 3D CAD model of the PCB. This model should include all of the copper features, such as traces, vias, and pads, as well as any other features that may affect the plating process, such as holes or slots.

- Meshing: Once the CAD model is created, it is then meshed into smaller elements. The mesh size and density can be adjusted to optimize the accuracy and speed of the simulation.

- Boundary Conditions: The next step is to define the boundary conditions for the simulation. This includes specifying the plating parameters, such as the current density, time, and temperature, as well as any constraints or limitations on the plating process.

- Simulation: With the boundary conditions defined, the simulation can be run. The simulation algorithm will model the flow of the plating solution over the surface of the PCB, taking into account factors such as the geometry of the board, the materials used, and the plating parameters.

- Results Analysis: Once the simulation is complete, the results can be analyzed to identify any potential issues with the design. This may include areas of uneven plating thickness, voids, or other defects that could affect the performance and reliability of the PCB.

PCB Plating Simulation in Action

To illustrate the benefits of PCB plating simulation, let’s look at a case study of a company that used plating simulation to optimize their PCB design.

The company was designing a high-density PCB for a medical device application. The PCB had a complex geometry with many small features, including vias and microvias. The company was concerned about the manufacturability of the design, particularly the ability to achieve uniform plating thickness across the entire board.

To address this concern, the company used PCB plating simulation to optimize their design. They created a 3D CAD model of the PCB and ran simulations with different plating parameters to identify the optimal settings for their design.

The simulation results showed that the original design had several areas of uneven plating thickness, particularly around the microvias. By adjusting the plating parameters and modifying the design to improve the flow of the plating solution, the company was able to achieve a more uniform plating thickness across the entire board.

As a result of the plating simulation, the company was able to reduce the number of manufacturing defects by 50% and improve the overall reliability of the PCB. They were also able to reduce the amount of material needed for plating, resulting in significant cost savings.

Implementing PCB Plating Simulation in Your Design Process

If you’re interested in implementing PCB plating simulation in your design process, there are a few key steps you can take:

- Invest in Plating Simulation Software: The first step is to invest in plating simulation software. There are several commercial software packages available, such as Elsyca’s PlatingMaster and Siemens’ PADS Professional. These software packages typically include a range of features, such as 3D CAD modeling, meshing, and simulation algorithms.

- Train Your Team: Once you have the software, it’s important to train your team on how to use it effectively. This may involve sending team members to training courses or workshops, or bringing in outside experts to provide on-site training.

- Integrate Plating Simulation into Your Design Process: To get the most benefit from plating simulation, it’s important to integrate it into your overall design process. This may involve incorporating plating simulation into your design reviews, or using it as a tool for design optimization and validation.

- Collaborate with Your Manufacturing Partners: Finally, it’s important to collaborate closely with your manufacturing partners to ensure that your plating simulations are accurate and relevant. This may involve sharing CAD models and simulation results with your manufacturing team, and working together to optimize the plating process for your specific designs.

FAQ

1. What is PCB plating simulation?

PCB plating simulation is a powerful tool that allows designers to simulate the plating process virtually, before the board is manufactured. By using plating simulation, designers can identify potential issues with their designs, such as uneven plating thickness, voids, or other defects that could affect the performance and reliability of the PCB.

2. What are the benefits of PCB plating simulation?

The benefits of PCB plating simulation include improved design quality, reduced manufacturing costs, and faster time-to-market. By identifying potential issues early in the design process, designers can avoid costly rework or scrap, and optimize their designs for plating to reduce material costs and improve reliability.

3. How does PCB plating simulation work?

PCB plating simulation works by using advanced algorithms to model the plating process virtually. The simulation takes into account a variety of factors, including the geometry of the PCB, the materials used, and the plating parameters, such as current density, time, and temperature. The simulation process typically involves creating a 3D CAD model of the PCB, meshing it into smaller elements, defining boundary conditions, running the simulation, and analyzing the results.

4. What software is available for PCB plating simulation?

There are several commercial software packages available for PCB plating simulation, such as Elsyca’s PlatingMaster and Siemens’ PADS Professional. These software packages typically include a range of features, such as 3D CAD modeling, meshing, and simulation algorithms.

5. How can I implement PCB plating simulation in my design process?

To implement PCB plating simulation in your design process, you should invest in plating simulation software, train your team on how to use it effectively, integrate plating simulation into your overall design process, and collaborate closely with your manufacturing partners to ensure that your simulations are accurate and relevant.

Conclusion

PCB plating simulation is a powerful tool that can help PCB designers create better, more reliable designs. By simulating the plating process virtually, designers can identify potential issues with their designs before the board is manufactured, resulting in improved design quality, reduced manufacturing costs, and faster time-to-market.

To get the most benefit from PCB plating simulation, it’s important to invest in the right software, train your team on how to use it effectively, and integrate it into your overall design process. By collaborating closely with your manufacturing partners and using plating simulation as a tool for design optimization and validation, you can create PCBs that are more reliable, cost-effective, and efficient to manufacture.

| Aspect | Benefit |

|---|---|

| Design Quality | Identify potential issues early, optimize design |

| Manufacturing Costs | Reduce rework, scrap, and material costs |

| Time-to-Market | Avoid delays, speed up manufacturing process |

As PCB designs continue to become more complex and the demand for faster time-to-market increases, PCB plating simulation will become an increasingly important tool for PCB designers. By embracing this technology and integrating it into your design process, you can stay ahead of the curve and create PCBs that meet the highest standards of quality and reliability.

No responses yet