What Are PCB Prototypes?

PCB prototypes are early versions of a printed circuit board that are used for testing and validation purposes. They are typically made in small quantities and are used to verify the functionality, performance, and manufacturability of a design before it goes into mass production.

Types of PCB Prototypes

There are several types of PCB prototypes, including:

- Breadboard Prototypes: These are used for initial circuit design and testing. They allow for quick and easy modifications to the circuit.

- Perfboard Prototypes: These are similar to breadboard prototypes but use a perforated board instead of a breadboard. They are more durable and can be used for more advanced testing.

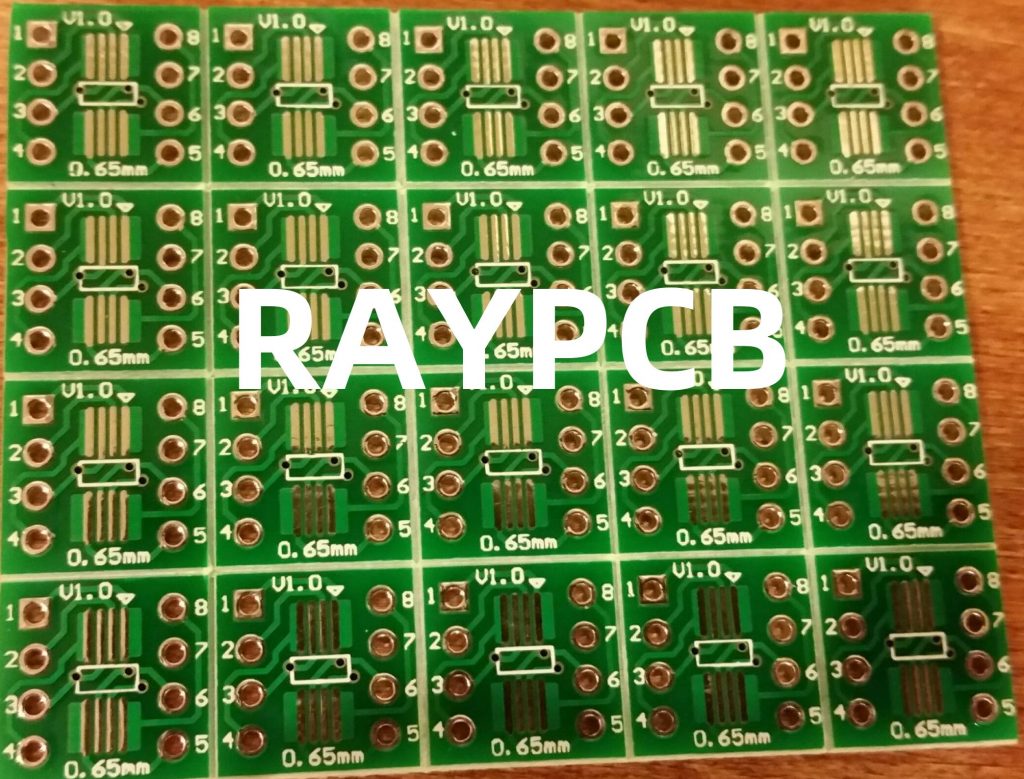

- PCB Prototypes: These are custom-made PCBs that are used for final testing and validation before mass production. They are typically made using the same materials and processes as the final product.

12 Insane But True Things About PCB Prototypes

- PCB prototypes can be made in just a few hours.

Thanks to advances in technology, PCB prototypes can now be made in just a few hours. This is thanks to rapid prototyping techniques such as 3D printing and CNC machining. This means that designers can quickly iterate on their designs and get them to market faster.

- PCB prototypes can be made with just a few clicks.

Many PCB prototype manufacturers now offer online ordering systems that allow designers to upload their designs and order prototypes with just a few clicks. This has made the process of getting PCB prototypes much easier and more accessible.

- PCB prototypes can be made for less than $5.

Thanks to increased competition and advances in manufacturing technology, the cost of PCB prototypes has dropped significantly in recent years. It is now possible to get a simple PCB prototype made for less than $5.

- PCB prototypes can be made in any shape or size.

PCB prototypes are not limited to standard shapes and sizes. They can be made in virtually any shape or size, including irregular and curved shapes. This allows designers to create PCBs that fit perfectly into their products.

- PCB prototypes can be made with multiple layers.

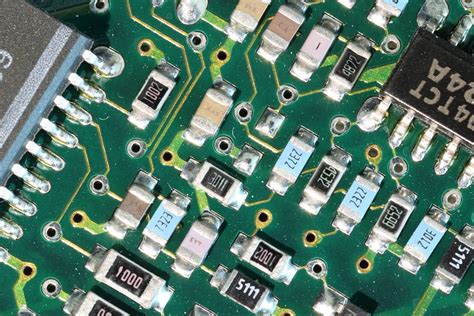

PCB prototypes can be made with multiple layers, allowing for more complex designs and higher component density. This is especially important for products that require a lot of functionality in a small space.

- PCB prototypes can be made with flexible materials.

PCB prototypes can be made with flexible materials such as polyimide or PEEK. This allows for the creation of flexible and bendable PCBs that can be used in wearable electronics and other applications.

- PCB prototypes can be made with embedded components.

PCB prototypes can be made with embedded components such as resistors, capacitors, and inductors. This allows for smaller and more compact designs, as well as improved reliability and performance.

- PCB prototypes can be made with high-speed materials.

PCB prototypes can be made with high-speed materials such as PTFE or Rogers. These materials have low dielectric constants and low loss tangents, making them ideal for high-speed applications such as 5G and radar.

- PCB prototypes can be made with advanced features.

PCB prototypes can be made with advanced features such as blind and buried vias, microvias, and HDI (high density interconnect). These features allow for more complex designs and higher component density.

- PCB prototypes can be tested for functionality and performance.

PCB prototypes can be tested for functionality and performance using a variety of methods, including:

- Continuity Testing: This tests for shorts and opens in the PCB.

- Resistance Testing: This tests for the resistance of traces and vias.

- Capacitance Testing: This tests for the capacitance between traces and planes.

- Functional Testing: This tests the overall functionality of the PCB.

- PCB prototypes can be used for compliance testing.

PCB prototypes can be used for compliance testing to ensure that they meet various regulatory standards such as FCC, CE, and UL. This is important for products that will be sold in different markets around the world.

- PCB prototypes can be used for marketing and sales.

PCB prototypes can be used for marketing and sales purposes, such as trade shows and customer demonstrations. They allow potential customers to see and touch the product, which can be a powerful sales tool.

Frequently Asked Questions About PCB Prototypes

Frequently Asked Questions About PCB Prototypes

- How long does it take to get a PCB prototype?

The time it takes to get a PCB prototype depends on the complexity of the design and the manufacturing process used. Simple designs can be made in just a few hours, while more complex designs may take several days or weeks.

- How much does a PCB prototype cost?

The cost of a PCB prototype depends on several factors, including the size, complexity, and quantity of the PCB. Simple PCBs can be made for less than $5, while more complex designs may cost several hundred dollars or more.

- What are the benefits of using PCB prototypes?

PCB prototypes offer several benefits, including:

- Allowing designers to test and refine their designs before mass production

- Reducing the risk of errors and defects in the final product

- Enabling faster time-to-market for new products

- Providing a tangible product for marketing and sales purposes

- What are the different types of PCB prototypes?

There are several types of PCB prototypes, including breadboard prototypes, perfboard prototypes, and custom PCB prototypes. Each type has its own advantages and disadvantages, and the best choice depends on the specific needs of the project.

- What should I consider when choosing a PCB prototype manufacturer?

When choosing a PCB prototype manufacturer, there are several factors to consider, including:

- The manufacturer’s experience and reputation

- The quality of their products and services

- Their turnaround time and pricing

- Their ability to handle complex designs and advanced features

- Their customer support and communication

| Factor | Description |

|---|---|

| Experience and Reputation | Look for a manufacturer with a proven track record of producing high-quality PCB prototypes. Read reviews and ask for references from other customers. |

| Quality | Make sure the manufacturer uses high-quality materials and processes to produce their PCB prototypes. Ask about their quality control measures and certifications. |

| Turnaround Time and Pricing | Consider the manufacturer’s turnaround time and pricing to ensure they can meet your project’s timeline and budget. Look for manufacturers that offer expedited services if needed. |

| Complex Designs and Advanced Features | If your project requires complex designs or advanced features such as HDI or embedded components, make sure the manufacturer has the capabilities to handle them. |

| Customer Support and Communication | Choose a manufacturer with responsive and helpful customer support. Make sure they communicate clearly and promptly throughout the project. |

Conclusion

PCB prototypes are an essential part of the electronics manufacturing process. They allow designers and engineers to test and refine their designs before mass production, reducing the risk of errors and defects in the final product.

As we have seen, there are many things about PCB prototypes that may be surprising or even insane. From their fast turnaround times and low costs to their ability to be made in any shape or size and with advanced features, PCB prototypes offer a wide range of benefits and capabilities.

When choosing a PCB prototype manufacturer, it is important to consider factors such as their experience, quality, turnaround time, pricing, and ability to handle complex designs and advanced features. By carefully evaluating these factors and choosing the right manufacturer for your project, you can ensure that your PCB prototypes are of the highest quality and meet your specific needs.

No responses yet