What is PCB Panelization?

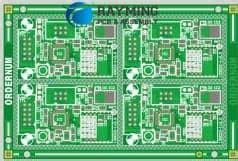

PCB panelization is the process of grouping multiple printed circuit board designs onto a single panel for manufacturing. This technique is used to increase production efficiency and reduce costs by allowing multiple PCBs to be fabricated simultaneously. Panelization is especially useful for small PCBs or high-volume production runs.

Benefits of PCB Panelization

- Cost reduction: Fabricating multiple PCBs on a single panel reduces the overall cost per unit.

- Increased efficiency: Panelization allows for faster assembly and testing of PCBs, as multiple boards can be processed simultaneously.

- Improved handling: Larger panels are easier to handle during the manufacturing process, reducing the risk of damage to individual PCBs.

- Consistent quality: Panelizing PCBs ensures consistent quality across all boards in the panel, as they are subjected to the same manufacturing conditions.

Types of PCB Panelization

There are two main types of PCB panelization: tab routing and scoring.

Tab Routing

Tab routing involves connecting individual PCBs on a panel using small tabs. These tabs are milled or routed out after the assembly process, allowing the PCBs to be easily separated. Tab routing is suitable for PCBs with simple shapes and designs.

Advantages of Tab Routing

- Easy to separate: PCBs can be easily separated from the panel by breaking the tabs.

- Flexible design: Tab routing allows for more flexibility in PCB design, as the tabs can be placed in various locations.

Disadvantages of Tab Routing

- Visible tabs: After separation, small tab remnants may be visible on the edges of the PCBs.

- Limited complexity: Tab routing may not be suitable for complex PCB designs or shapes.

Scoring

Scoring involves creating grooves or perforations along the edges of individual PCBs on a panel. These grooves allow the PCBs to be easily separated by breaking along the score lines. Scoring is suitable for PCBs with more complex shapes or designs.

Advantages of Scoring

- Clean edges: Scoring results in clean, smooth edges on the separated PCBs.

- Complex designs: Scoring can accommodate more complex PCB designs and shapes.

Disadvantages of Scoring

- Reduced structural integrity: The grooves created during scoring may slightly reduce the structural integrity of the PCBs.

- Specialized equipment: Scoring requires specialized equipment and may be more expensive than tab routing.

PCB Panelization Design Considerations

When designing a PCB panel, several factors must be considered to ensure optimal results.

Panel Size and Material

The size and material of the panel should be chosen based on the specific requirements of the project. Common panel sizes include:

| Panel Size | Dimensions (mm) |

|---|---|

| Small | 100 x 100 |

| Medium | 200 x 200 |

| Large | 300 x 300 |

The most common material for PCB panels is FR-4, a glass-reinforced epoxy laminate. Other materials, such as aluminum or flexible substrates, may be used for specific applications.

Spacing and Clearance

Adequate spacing and clearance between individual PCBs on the panel is crucial to ensure proper fabrication and assembly. The following guidelines should be followed:

- Minimum spacing between PCBs: 2 mm

- Minimum clearance between PCB edges and panel edges: 5 mm

- Minimum clearance between PCB Components and panel edges: 3 mm

Fiducial Marks

Fiducial marks are reference points used by assembly machines to accurately place components on the PCBs. It is essential to include fiducial marks on the panel design to ensure precise alignment during the assembly process.

Tooling Holes

Tooling holes are used to secure the panel during the fabrication and assembly processes. The size and location of tooling holes should be specified in the panel design, following the manufacturer’s guidelines.

PCB Panelization at Screaming Circuits

Screaming Circuits is a leading provider of PCB Assembly services, offering high-quality PCB panelization for various applications. With state-of-the-art equipment and experienced technicians, Screaming Circuits ensures that your PCB panels are fabricated to the highest standards.

Panelization Services Offered

- Tab routing

- Scoring

- Custom panelization designs

- Multi-layer PCB panelization

- High-volume production runs

Advantages of Choosing Screaming Circuits for PCB Panelization

- Expertise: Screaming Circuits has extensive experience in PCB panelization, ensuring optimal results for your projects.

- Quality: Strict quality control measures are in place to guarantee the consistency and reliability of your PCB panels.

- Fast turnaround: With efficient processes and advanced equipment, Screaming Circuits can deliver your panelized PCBs quickly.

- Cost-effective: Competitive pricing and volume discounts make Screaming Circuits an affordable choice for PCB panelization.

Case Studies

Case Study 1: Wearable Technology Device

A wearable technology startup approached Screaming Circuits to panelize their compact PCB design for mass production. Screaming Circuits developed a custom panel design using tab routing, accommodating the unique shape of the PCBs while ensuring efficient fabrication and assembly. The result was a cost-effective, high-quality solution that allowed the startup to bring their product to market quickly.

Case Study 2: Industrial Control System

An industrial automation company required a large number of PCBs for their new control system. Screaming Circuits utilized scoring panelization to create panels that could accommodate the complex shapes of the PCBs while maintaining structural integrity. The panelized PCBs were fabricated and assembled efficiently, meeting the company’s strict deadlines and quality requirements.

FAQ

- What is the minimum order quantity for PCB panelization at Screaming Circuits?

-

Screaming Circuits has no minimum order quantity for PCB panelization. We can accommodate orders of any size, from prototype quantities to high-volume production runs.

-

How long does the PCB panelization process take?

-

The turnaround time for PCB panelization depends on the complexity of the design and the volume of the order. Typically, Screaming Circuits can complete the panelization process within 1-2 weeks, with expedited options available for urgent projects.

-

Can Screaming Circuits panelize multi-layer PCBs?

-

Yes, Screaming Circuits has the capability to panelize multi-layer PCBs. Our advanced equipment and experienced technicians can handle the challenges associated with panelizing complex, multi-layer designs.

-

What file formats does Screaming Circuits accept for PCB panelization?

-

Screaming Circuits accepts various file formats for PCB panelization, including Gerber files, ODB++, and IPC-2581. We recommend providing the most comprehensive and up-to-date design files to ensure accurate panelization.

-

Does Screaming Circuits offer design assistance for PCB panelization?

- Yes, Screaming Circuits offers design assistance and consultation services for PCB panelization. Our experienced engineers can review your PCB design and provide recommendations to optimize it for panelization, ensuring the best possible results for your project.

Conclusion

PCB panelization is a crucial technique for optimizing the fabrication and assembly of printed circuit boards. By grouping multiple PCBs onto a single panel, manufacturers can reduce costs, increase efficiency, and ensure consistent quality. Screaming Circuits is a trusted partner for PCB panelization, offering a range of services and expertise to meet the needs of various applications. With a focus on quality, efficiency, and customer satisfaction, Screaming Circuits is the ideal choice for your PCB panelization requirements.

No responses yet