Introduction to Multilayer PCB Manufacturing

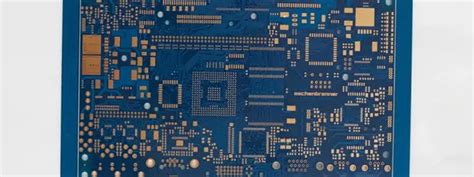

In today’s rapidly advancing electronic industry, multilayer printed circuit boards (PCBs) have become an essential component in various applications, from consumer electronics to aerospace systems. Multilayer PCBs offer numerous advantages over traditional single or double-layer boards, including increased circuit density, improved signal integrity, and reduced electromagnetic interference (EMI). This article will delve into the intricacies of multilayer PCB manufacturing, focusing on the production of boards with 3 to 64 layers.

What is a Multilayer PCB?

A multilayer PCB is a printed circuit board that consists of three or more conductive copper layers separated by insulating dielectric materials. These layers are interconnected through carefully designed vias and plated through-holes (PTHs) to create a complex network of electrical connections. By utilizing multiple layers, designers can optimize board space, minimize signal interference, and improve overall system performance.

Benefits of Multilayer PCBs

- Increased circuit density

- Improved signal integrity

- Reduced electromagnetic interference (EMI)

- Enhanced thermal management

- Miniaturization of electronic devices

The Manufacturing Process of Multilayer PCBs

Step 1: Design and Preparation

The multilayer PCB manufacturing process begins with the design and preparation of the board layout. Using advanced PCB design software, engineers create a detailed schematic and layout of the circuit, taking into account factors such as signal integrity, power distribution, and component placement. The design files are then converted into Gerber format, which is the industry standard for PCB Fabrication.

Step 2: Inner Layer Fabrication

Once the design is finalized, the inner layers of the multilayer PCB are fabricated. This process involves the following sub-steps:

- Material selection and cutting

- Copper foil lamination

- Dry film application

- Exposure and development

- Etching

- Inspection and cleaning

Step 3: Layer Stacking and Lamination

After the inner layers are fabricated, they are stacked together with insulating dielectric materials, such as prepreg (pre-impregnated fiberglass) and copper foil, in a specific order according to the design. The stack is then subjected to high pressure and temperature in a lamination press, bonding the layers together to form a solid board.

Step 4: Drilling and Plating

To interconnect the layers, holes are drilled through the laminated board using high-precision drilling machines. These holes are then plated with copper to create conductive pathways between the layers, forming vias and PTHs. The plating process typically involves the following sub-steps:

- Desmear

- Electroless copper deposition

- Electrolytic copper plating

Step 5: Outer Layer Processing

With the inner layers interconnected, the outer layers of the multilayer PCB are processed. This stage involves similar steps to inner layer fabrication, including:

- Dry film application

- Exposure and development

- Etching

- Soldermask application

- Silkscreen printing

Step 6: Surface Finishing

To protect the exposed copper and enhance solderability, a surface finish is applied to the PCB. Common surface finishes include:

- Hot Air Solder Leveling (HASL)

- Electroless Nickel Immersion Gold (ENIG)

- Immersion Silver (IAg)

- Immersion Tin (ISn)

- Organic Solderability Preservative (OSP)

Step 7: Electrical Testing and Inspection

Before the multilayer PCB is deemed complete, it undergoes rigorous electrical testing and inspection to ensure functionality and adherence to design specifications. This step may include:

- Flying probe testing

- Automated optical inspection (AOI)

- X-ray inspection

- Microsectioning

Challenges in Multilayer PCB Manufacturing

As the number of layers in a multilayer PCB increases, so do the manufacturing challenges. Some of the key challenges include:

Signal Integrity

With the increasing complexity of multilayer PCBs, maintaining signal integrity becomes a critical concern. Factors such as crosstalk, impedance mismatch, and signal loss can lead to performance degradation and reliability issues. To mitigate these problems, careful design considerations and advanced manufacturing techniques are employed, such as controlled impedance routing and high-speed material selection.

Thermal Management

As circuit density increases in multilayer PCBs, thermal management becomes a significant challenge. The buildup of heat within the board can lead to component failure and reduced reliability. To address this issue, designers incorporate thermal management strategies, such as the use of thermal vias, heat sinks, and specialized dielectric materials with high thermal conductivity.

Layer Registration and Alignment

Ensuring accurate layer registration and alignment is critical in multilayer PCB manufacturing, especially as the number of layers increases. Misalignment can lead to poor interconnections, signal integrity issues, and even short circuits. Advanced registration systems and precision manufacturing equipment are employed to maintain tight tolerances and minimize alignment errors.

Yield and Reliability

As the complexity of multilayer PCBs increases, maintaining high yield and reliability becomes more challenging. Defects such as delamination, voids, and shorts can occur during the manufacturing process, leading to reduced yield and potential reliability issues in the field. Strict quality control measures, including automated inspection systems and statistical process control, are implemented to identify and address defects early in the manufacturing process.

Advancements in Multilayer PCB Manufacturing

To address the challenges associated with multilayer PCB manufacturing and meet the ever-increasing demands of the electronics industry, several advancements have been made in recent years:

High-Density Interconnect (HDI) Technology

HDI technology involves the use of microvias and fine-pitch traces to achieve higher circuit densities and improved signal integrity in multilayer PCBs. By employing advanced fabrication techniques, such as laser drilling and sequential lamination, HDI PCBs can accommodate a greater number of components and interconnections in a smaller footprint.

Embedded Components

Embedded component technology allows for the integration of passive components, such as resistors and capacitors, directly within the layers of a multilayer PCB. This approach saves valuable board space, reduces the number of solder joints, and improves overall system reliability. Embedded components are particularly beneficial in applications that require miniaturization and high-density packaging.

3D Printed Electronics

The advent of 3D printing technology has opened up new possibilities for multilayer PCB manufacturing. By utilizing conductive and insulating materials, 3D printers can create complex, three-dimensional PCB structures with embedded components and interconnects. This technology enables rapid prototyping, customization, and the creation of unique form factors that would be difficult or impossible to achieve with traditional manufacturing methods.

Choosing a Multilayer PCB Manufacturer

When selecting a multilayer PCB manufacturer, it is essential to consider several key factors to ensure the quality, reliability, and timely delivery of your boards:

Technical Capabilities

Ensure that the manufacturer has the necessary technical capabilities to produce multilayer PCBs with the required number of layers, materials, and features. Inquire about their experience with similar projects and their ability to meet your specific design requirements.

Quality Management System

Choose a manufacturer with a robust quality management system in place, such as ISO 9001 certification. This ensures that they adhere to strict quality control standards throughout the manufacturing process, from incoming material inspection to final testing and inspection.

Lead Time and Delivery

Consider the manufacturer’s lead time and delivery performance. Look for a supplier that can meet your project deadlines and has a track record of timely delivery. Inquire about their communication processes and how they handle potential delays or issues that may arise during production.

Cost and Value

While cost is an important consideration, it should not be the sole determining factor when choosing a multilayer PCB manufacturer. Evaluate the overall value proposition, taking into account factors such as quality, reliability, technical support, and after-sales service. A slightly higher initial cost may be justified if it results in superior quality and long-term reliability.

Frequently Asked Questions (FAQ)

- What is the maximum number of layers that can be achieved in a multilayer PCB?

-

The maximum number of layers in a multilayer PCB is typically 64, although some specialized manufacturers may be able to produce boards with even more layers. However, as the number of layers increases, so do the manufacturing challenges and costs.

-

What are the advantages of using HDI technology in multilayer PCBs?

-

HDI technology offers several advantages, including increased circuit density, improved signal integrity, and reduced board size. By utilizing microvias and fine-pitch traces, HDI PCBs can accommodate more components and interconnections in a smaller footprint, enabling the miniaturization of electronic devices.

-

How does the number of layers affect the cost of a multilayer PCB?

- The cost of a multilayer PCB generally increases with the number of layers. This is due to the increased complexity of the manufacturing process, the need for additional materials, and the higher level of precision required. The table below provides a rough estimate of the cost increase as the number of layers grows:

| Number of Layers | Cost Increase |

|---|---|

| 4-6 | 20-40% |

| 8-10 | 40-60% |

| 12-16 | 60-80% |

| 18-24 | 80-100% |

| 26+ | 100%+ |

- What is the typical lead time for multilayer PCB manufacturing?

-

The lead time for multilayer PCB manufacturing varies depending on the complexity of the design, the number of layers, and the manufacturer’s capacity. Typical lead times range from 2-3 weeks for standard multilayer PCBs (4-8 layers) to 4-6 weeks for more complex designs (12+ layers). Expedited services may be available for an additional cost.

-

Can multilayer PCBs be reworked or repaired?

- Reworking or repairing multilayer PCBs can be challenging due to the complex nature of their construction. In many cases, it may be more cost-effective to replace a faulty board rather than attempting to repair it. However, skilled technicians with specialized equipment can perform limited rework, such as replacing components or repairing damaged traces, depending on the extent of the damage and the accessibility of the affected area.

Conclusion

Multilayer PCB manufacturing is a complex and critical process in the production of modern electronic devices. By understanding the intricacies of the manufacturing process, the challenges involved, and the advancements in technology, designers and engineers can make informed decisions when developing and sourcing multilayer PCBs. Choosing a reputable and experienced manufacturer is essential to ensure the quality, reliability, and timely delivery of your boards, ultimately contributing to the success of your electronic products.

As the demand for more compact, high-performance electronic devices continues to grow, the importance of multilayer PCB manufacturing will only increase. By staying abreast of the latest developments in materials, processes, and technologies, the electronics industry can continue to push the boundaries of what is possible in the realm of multilayer PCBs, enabling the creation of ever-more sophisticated and capable electronic systems.

No responses yet