Introduction

When designing an electronic project, one of the most critical decisions you’ll make is choosing the right PCB (Printed Circuit Board) material. The PCB serves as the foundation for your electronic components and plays a crucial role in the overall performance, reliability, and longevity of your device. With a wide range of PCB materials available, each with its unique properties and characteristics, it can be challenging to determine which one best suits your project’s requirements. In this comprehensive guide, we’ll explore the factors you need to consider when selecting a PCB material and provide you with the knowledge to make an informed decision.

Understanding PCB Materials

What is a PCB?

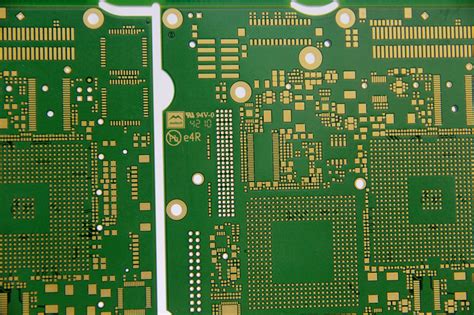

A Printed Circuit Board (PCB) is a flat, insulated board that supports and connects electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate. PCBs are used in nearly all electronic devices, from simple single-layer boards to complex multi-layer boards found in advanced electronic systems.

Common PCB Materials

There are several common PCB materials used in the industry, each with its own set of properties and advantages:

- FR-4 (Flame Retardant 4):

- Glass-reinforced epoxy laminate

- Most widely used PCB material

- Suitable for general-purpose applications

- Good mechanical and electrical properties

-

Cost-effective

-

Polyimide:

- High-temperature resistance

- Excellent mechanical and electrical properties

- Suitable for aerospace, military, and high-reliability applications

-

More expensive than FR-4

-

PTFE (Polytetrafluoroethylene):

- Low dielectric constant and dissipation factor

- Excellent high-frequency performance

- Suitable for RF and microwave applications

-

Relatively expensive

-

Alumina:

- Ceramic material

- High thermal conductivity

- Suitable for high-power and high-frequency applications

- Excellent dimensional stability

-

Brittle and expensive

-

Metal Core:

- Aluminum or copper core with a dielectric layer

- High thermal conductivity

- Suitable for high-power LED lighting and power electronics

- Efficient heat dissipation

Factors to Consider When Choosing a PCB Material

When selecting a PCB material for your electronic project, there are several key factors to consider. These factors will help you determine which material is best suited for your specific application and ensure optimal performance and reliability.

1. Electrical Properties

The electrical properties of a PCB material are crucial in determining its suitability for your project. Some important electrical properties to consider include:

-

Dielectric Constant (Dk): A measure of the material’s ability to store electrical energy. A lower Dk value is desirable for high-frequency applications to minimize signal loss and distortion.

-

Dissipation Factor (Df): A measure of the material’s ability to dissipate electrical energy as heat. A lower Df value is preferred to minimize signal loss and maintain signal integrity.

-

Insulation Resistance: The material’s ability to resist the flow of electrical current. Higher insulation resistance is essential to prevent leakage currents and maintain signal integrity.

2. Thermal Properties

The thermal properties of a PCB material determine its ability to withstand and dissipate heat generated by electronic components. Key thermal properties to consider include:

-

Glass Transition Temperature (Tg): The temperature at which the material transitions from a rigid, glassy state to a softer, rubbery state. A higher Tg value indicates better thermal stability and resistance to deformation at elevated temperatures.

-

Thermal Conductivity: The material’s ability to conduct heat. Higher thermal conductivity allows for better heat dissipation, which is essential for high-power applications and preventing component overheating.

-

Coefficient of Thermal Expansion (CTE): The material’s tendency to expand or contract with changes in temperature. A lower CTE value is desirable to minimize stress on components and solder joints caused by thermal cycling.

3. Mechanical Properties

The mechanical properties of a PCB material determine its ability to withstand physical stresses and maintain structural integrity. Important mechanical properties to consider include:

-

Flexural Strength: The material’s ability to resist bending and maintain its shape under stress. Higher flexural strength is essential for applications where the PCB may be subject to physical stress or vibration.

-

Tensile Strength: The material’s ability to resist pulling forces without breaking. Higher tensile strength is important for applications where the PCB may be subject to stretching or pulling.

-

Impact Resistance: The material’s ability to withstand sudden impacts without cracking or breaking. Higher impact resistance is crucial for applications where the PCB may be exposed to shock or rough handling.

4. Environmental Factors

The environment in which your electronic project will operate can have a significant impact on the choice of PCB material. Consider the following environmental factors:

-

Operating Temperature Range: Ensure that the selected PCB material can withstand the expected operating temperature range of your project without deterioration or loss of performance.

-

Humidity Resistance: If your project will be exposed to high humidity levels, choose a PCB material with good moisture resistance to prevent degradation and maintain reliability.

-

Chemical Resistance: If your project will be exposed to chemicals or solvents, select a PCB material that can withstand these substances without deterioration.

5. Manufacturing Considerations

The manufacturability of a PCB material is an essential factor to consider, as it can impact the cost, lead time, and overall feasibility of your project. Some manufacturing considerations include:

-

Availability: Ensure that the selected PCB material is readily available from suppliers and manufacturers to avoid delays and supply chain issues.

-

Processability: Consider the ease of processing the PCB material, including drilling, routing, and plating. Some materials may require specialized equipment or processes, which can increase manufacturing costs and lead times.

-

Cost: Evaluate the cost of the PCB material in relation to your project’s budget and overall cost constraints. While some high-performance materials may offer superior properties, they may also come at a higher price point.

PCB Material Selection Guide

To help you navigate the process of selecting the right PCB material for your electronic project, we’ve created a handy selection guide. This guide takes into account the various factors discussed above and provides recommendations based on common application requirements.

| Application | Key Requirements | Recommended PCB Materials |

|---|---|---|

| General-purpose | Cost-effective, good mechanical and electrical properties | FR-4, CEM-1, CEM-3 |

| High-frequency (RF/Microwave) | Low dielectric constant and dissipation factor, high-frequency performance | PTFE, Rogers RO4000 series, Isola IS680 |

| High-temperature | Thermal stability, high glass transition temperature | Polyimide, FR-4 high Tg, Rogers RO4000 series |

| High-power | Thermal conductivity, efficient heat dissipation | Metal Core (Aluminum or Copper), Ceramic (Alumina) |

| Flexible | Flexibility, mechanical strength | Polyimide, Polyester |

| High-reliability | Mechanical and thermal stability, resistance to environmental factors | Polyimide, FR-4 high Tg, PTFE |

FAQ

-

Q: What is the most commonly used PCB material for general-purpose applications?

A: FR-4 is the most widely used PCB material for general-purpose applications due to its good mechanical and electrical properties, as well as its cost-effectiveness. -

Q: Which PCB materials are suitable for high-frequency applications?

A: For high-frequency applications, such as RF and microwave circuits, PCB materials with low dielectric constant and dissipation factor are recommended. PTFE, Rogers RO4000 series, and Isola IS680 are popular choices for these applications. -

Q: What are the advantages of using Metal Core PCBs?

A: Metal core PCBs, typically made with aluminum or copper cores, offer high thermal conductivity and efficient heat dissipation. This makes them suitable for high-power applications, such as LED lighting and power electronics, where heat management is critical. -

Q: Are there any special considerations when selecting PCB materials for flexible applications?

A: When choosing PCB materials for flexible applications, it’s essential to consider the material’s flexibility and mechanical strength. Polyimide and polyester are commonly used for Flexible PCBs due to their ability to withstand repeated bending and flexing without cracking or breaking. -

Q: How can I ensure the reliability of my PCB in harsh environmental conditions?

A: To ensure the reliability of your PCB in harsh environmental conditions, select materials with high mechanical and thermal stability, as well as resistance to environmental factors such as humidity and chemicals. Polyimide, FR-4 with high Tg, and PTFE are known for their excellent performance in demanding environments.

Conclusion

Choosing the right PCB material for your electronic project is a critical decision that can significantly impact the performance, reliability, and overall success of your device. By understanding the various factors to consider, such as electrical, thermal, and mechanical properties, as well as environmental and manufacturing considerations, you can make an informed decision and select the material that best suits your project’s requirements.

Remember to consult the PCB material selection guide provided in this article as a starting point, but always consider the unique needs and constraints of your specific application. Don’t hesitate to consult with PCB manufacturers, material suppliers, and industry experts to gather more information and guidance when making your final decision.

By taking the time to carefully evaluate your options and choose the right PCB material, you can ensure that your electronic project has a solid foundation for success, reliability, and long-term performance.

No responses yet