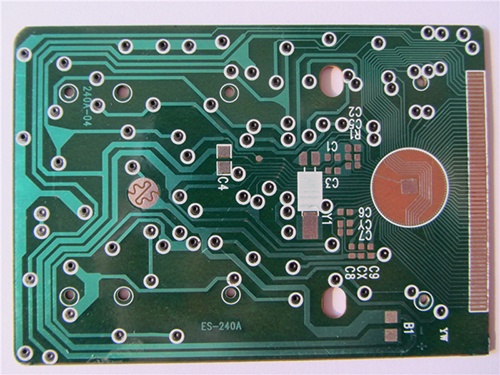

Understanding Your PCB Requirements

Defining PCB Specifications

Before beginning the procurement process, it’s essential to clearly define your PCB specifications. Consider the following factors:

– Board size and thickness

– Number of layers

– Material (e.g., FR-4, high-frequency, flexible)

– Copper weight and trace width

– Surface finish (e.g., HASL, ENIG, OSP)

– Special requirements (e.g., impedance control, blind/buried vias)

Having a detailed specification document will help you communicate your requirements effectively to potential suppliers and ensure you receive accurate quotes.

PCB Design Optimization

Optimizing your PCB design can significantly impact the cost and manufacturability of your boards. Consider the following best practices:

– Minimize board size and layer count

– Use standard component sizes and footprints

– Avoid tight tolerances unless necessary

– Ensure proper spacing and clearances

– Follow the manufacturer’s design guidelines

By optimizing your design, you can reduce manufacturing complexity, improve yields, and lower production costs.

Sourcing PCB Suppliers

Identifying Potential Suppliers

Once you have defined your PCB requirements, it’s time to identify potential suppliers. There are several ways to find PCB Manufacturers:

– Online directories and marketplaces (e.g., PCBShopper, PCBDirectory)

– Industry associations and trade shows

– Referrals from colleagues or industry partners

– Search engines and supplier websites

Create a list of potential suppliers that meet your criteria, such as manufacturing capabilities, certifications, and location.

Evaluating Supplier Capabilities

Before requesting quotes, evaluate each supplier’s capabilities to ensure they can meet your requirements. Consider the following factors:

– Manufacturing technology and equipment

– Quality certifications (e.g., ISO 9001, UL, IPC)

– Minimum order quantities (MOQs) and lead times

– Customer support and communication

– Intellectual property (IP) protection

– Financial stability and reputation

Request information and references from potential suppliers to assess their suitability for your project.

Requesting and Evaluating Quotes

Request for Quote (RFQ) Process

Once you have identified suitable suppliers, it’s time to request quotes. Prepare a detailed RFQ package that includes:

– PCB specifications and design files

– Quantity and delivery requirements

– Testing and inspection requirements

– Any special instructions or preferences

Send the RFQ package to multiple suppliers to obtain competitive quotes and lead times.

Evaluating Quotes and Negotiating Terms

Upon receiving quotes from suppliers, evaluate them based on the following criteria:

– Price and cost breakdown

– Lead time and delivery schedule

– Quality and testing provisions

– Payment terms and conditions

– Value-added services (e.g., design support, inventory management)

Compare the quotes and negotiate terms with the most promising suppliers. Don’t hesitate to ask for clarifications or request adjustments to ensure the best value for your project.

Managing the PCB Procurement Process

Placing the Order

Once you have selected a supplier and agreed upon the terms, place a formal purchase order (PO). The PO should include:

– DetaiLED PCB specifications and quantities

– Agreed-upon price and payment terms

– Delivery date and shipping instructions

– Quality and testing requirements

– Any special instructions or references

Ensure that all terms and conditions are clearly documented to avoid misunderstandings or disputes.

Quality Control and Inspection

To ensure the quality of your PCBs, establish a robust quality control and inspection process. This may include:

– Incoming inspection of PCBs

– Functional and reliability testing

– Visual inspection for defects and workmanship

– Compliance with industry standards (e.g., IPC-A-600, IPC-6012)

Work closely with your supplier to define quality expectations and resolve any issues promptly.

Managing Inventory and Supply Chain

Effective PCB procurement also involves managing inventory and supply chain risks. Consider the following strategies:

– Establish a safety stock to buffer against demand fluctuations or supply disruptions

– Implement a just-in-time (JIT) inventory system to minimize carrying costs

– Diversify your supplier base to mitigate risks

– Monitor supplier performance and conduct regular audits

– Develop a contingency plan for supply chain disruptions

By proactively managing your inventory and supply chain, you can ensure a steady supply of PCBs while minimizing costs and risks.

Cost Optimization Strategies

Volume Discounts and Bulk Ordering

One of the most effective ways to reduce PCB procurement costs is to leverage volume discounts and bulk ordering. Many suppliers offer reduced prices for larger order quantities. Consider the following strategies:

– Consolidate multiple smaller orders into larger batches

– Negotiate volume discounts based on annual or long-term purchase commitments

– Explore consignment or vendor-managed inventory (VMI) arrangements

By increasing your order quantities and negotiating volume discounts, you can significantly reduce your per-unit PCB costs.

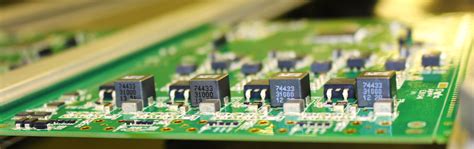

Design for Manufacturability (DFM)

Designing your PCBs with manufacturability in mind can help reduce production costs and improve yields. Consider the following DFM best practices:

– Use standard materials and processes whenever possible

– Minimize the use of non-standard or custom components

– Avoid unnecessary complexity and tight tolerances

– Follow the manufacturer’s design guidelines and rules

– Conduct DFM reviews with your supplier before finalizing the design

By optimizing your PCB design for manufacturability, you can reduce production costs, improve quality, and accelerate time-to-market.

Strategic Sourcing and Supplier Relationships

Building strong relationships with your PCB suppliers can lead to cost savings and improved service levels. Consider the following strategies:

– Develop long-term partnerships with key suppliers

– Share demand forecasts and production schedules

– Collaborate on cost reduction initiatives and continuous improvement

– Explore value-added services and support options

– Foster open communication and transparency

By cultivating strategic supplier relationships, you can access better pricing, priority service, and value-added support.

Frequently Asked Questions (FAQ)

- How do I choose the right PCB supplier for my project?

When selecting a PCB supplier, consider factors such as manufacturing capabilities, quality certifications, pricing, lead times, and customer support. Evaluate multiple suppliers and request quotes to compare options and find the best fit for your specific requirements. - What are the most common PCB materials, and how do I choose the right one?

The most common PCB materials include FR-4, high-frequency laminates, and flexible substrates. The choice of material depends on your application’s requirements, such as electrical performance, thermal stability, and mechanical properties. Consult with your supplier or industry experts to select the most suitable material for your project. - How can I ensure the quality of my PCBs during the procurement process?

To ensure PCB quality, establish clear quality specifications and requirements in your RFQ and purchase order. Work with suppliers who have robust quality management systems and industry certifications. Implement incoming inspection and testing procedures to verify the quality of received PCBs, and address any issues promptly with your supplier. - What are the typical lead times for PCB procurement, and how can I minimize them?

PCB lead times can vary depending on factors such as complexity, quantity, and supplier capacity. Typical lead times range from a few days for standard designs to several weeks for complex or customized boards. To minimize lead times, provide complete and accurate specifications, place orders in advance, and maintain open communication with your supplier. Consider expedited manufacturing options for time-critical projects. - How can I manage the risks associated with PCB procurement, such as supply chain disruptions or quality issues?

To mitigate PCB procurement risks, diversify your supplier base to avoid reliance on a single source. Establish contingency plans and maintain safety stock to buffer against supply disruptions. Implement robust quality control processes and regularly audit your suppliers. Foster strong relationships with your suppliers and maintain open communication to address any issues promptly and collaboratively.

Conclusion

Effective PCB procurement is essential for meeting customer demands and ensuring the success of your electronics manufacturing projects. By understanding your PCB requirements, sourcing reliable suppliers, evaluating quotes, and managing the procurement process, you can obtain high-quality PCBs that meet your specifications while optimizing costs.

Remember to focus on design optimization, strategic sourcing, and continuous improvement to drive long-term cost savings and supply chain efficiency. By following the best practices and strategies outlined in this guide, you can navigate the complexities of PCB procurement and build a robust and cost-effective supply chain for your organization.

No responses yet