In the electronics manufacturing industry, the cost of assembling a printed circuit board (PCB) is a critical factor that influences decision-making and pricing strategies. PCB assembly is a complex process that involves various components, materials, and techniques, each contributing to the overall cost. Understanding the factors that impact the cost of PCB assembly is essential for manufacturers, designers, and procurement professionals to make informed decisions and optimize their operations.

Factors Affecting PCB Assembly Cost

The cost of PCB assembly is influenced by several factors, ranging from the complexity of the design to the volume of production, the choice of components, and the manufacturing processes involved. Let’s explore these factors in detail:

1. Design Complexity

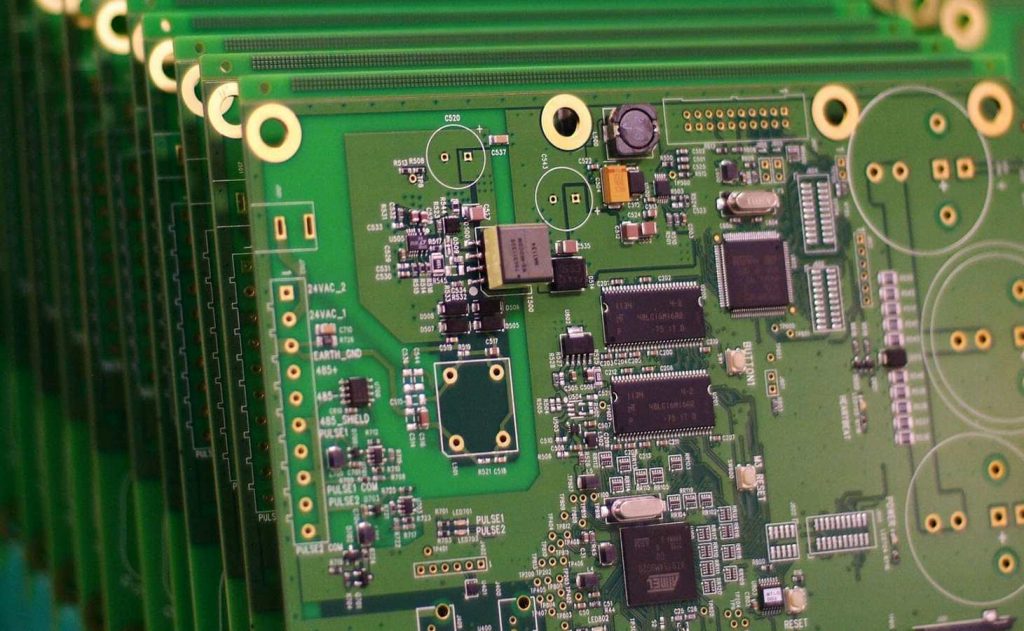

The complexity of the PCB design plays a significant role in determining the assembly cost. Factors such as the number of layers, component density, and the presence of specialized components can increase the overall cost. Complex designs often require more advanced assembly techniques, specialized equipment, and additional processing steps, which translate into higher costs.

2. Component Selection

The choice of electronic components is another crucial factor that impacts the cost of PCB assembly. Components can vary significantly in price, depending on their type, packaging, and availability. Using high-end or specialized components can substantially increase the overall cost, while opting for more readily available and cost-effective alternatives can help reduce expenses.

3. Component Packaging

The packaging of electronic components also influences the assembly cost. Surface-mount components (SMDs) generally require more advanced assembly techniques and specialized equipment compared to through-hole components. Additionally, components with smaller package sizes (e.g., 0201, 01005) or ball grid array (BGA) packages can further increase the complexity and cost of the assembly process.

4. Board Size and Complexity

The size and complexity of the PCB itself can affect the assembly cost. Larger boards may require more components, increasing material and labor costs. Additionally, boards with complex layouts, tight tolerances, or specialized features (e.g., high-density interconnects, embedded components) can drive up the assembly cost due to the additional processing steps and specialized equipment required.

5. Production Volume

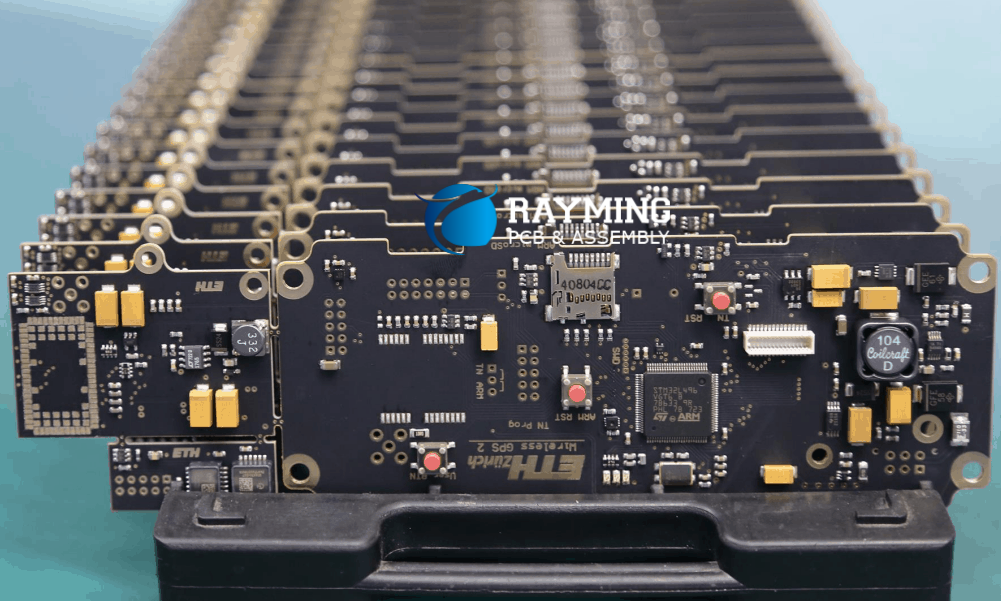

The production volume plays a significant role in determining the cost of PCB assembly. High-volume production generally benefits from economies of scale, reducing the per-unit cost. Conversely, low-volume or prototyping runs often incur higher costs due to setup times, programming, and the inability to leverage volume discounts.

6. Manufacturing Process

The manufacturing process chosen for PCB assembly can also impact the overall cost. Common assembly processes include surface mount technology (SMT), through-hole technology (THT), and mixed assembly (a combination of SMT and THT). SMT assembly typically requires more specialized equipment and higher initial investment but offers higher throughput and lower labor costs. THT assembly, on the other hand, is more labor-intensive but may be more cost-effective for low-volume or specialized applications.

7. Labor Costs

Labor costs are a significant factor in PCB assembly, particularly for manual assembly or operations that require human intervention. The cost of labor can vary significantly based on the geographic location of the manufacturing facility, skill level required, and the degree of automation employed in the assembly process.

8. Quality Requirements

The quality requirements for the assembled PCBs can also impact the overall cost. More stringent quality standards may necessitate additional testing, inspection, and quality control measures, which can increase the cost of assembly. Certifications, such as IPC (Institute for Printed Circuits) or industry-specific standards, may also add to the overall cost.

9. Shipping and Logistics

Shipping and logistics costs can contribute to the overall cost of PCB assembly, particularly for overseas manufacturing or when sourcing components from multiple suppliers. Factors such as transportation, customs duties, and inventory management can add to the overall expenses.

10. Overhead and Operating Costs

Finally, overhead and operating costs associated with running a PCB assembly facility, including utilities, maintenance, administrative expenses, and other overheads, should be factored into the overall cost of assembly.

Cost Estimation Techniques

To estimate the cost of PCB assembly accurately, manufacturers often employ various techniques and tools. Here are some common approaches:

1. Bottom-Up Costing

Bottom-up costing involves estimating the cost of each individual component, material, and process involved in the assembly process and then summing them up to calculate the total cost. This method provides a detailed and granular cost breakdown but can be time-consuming for complex assemblies.

2. Top-Down Costing

Top-down costing takes a more generalized approach by estimating the overall cost based on historical data or industry averages for similar assemblies. While less accurate than bottom-up costing, this method can provide a quick estimate and is useful for early-stage budgeting and planning.

3. Parametric Cost Estimation

Parametric cost estimation uses statistical models and algorithms to estimate the cost based on key parameters or characteristics of the PCB assembly. These models are typically developed from historical data and can provide reasonably accurate estimates for similar assemblies.

4. Expert Judgment and Quotes

In some cases, manufacturers may rely on expert judgment and quotes from experienced PCB assembly providers or vendors. This approach can provide valuable insights and realistic cost estimates, especially for complex or specialized assemblies.

5. Cost Estimation Software and Tools

Various software tools and cost estimation packages are available in the market to assist manufacturers in estimating the cost of PCB assembly. These tools often incorporate industry data, cost models, and advanced algorithms to provide accurate cost estimates based on the provided design and assembly specifications.

Cost Optimization Strategies

While the cost of PCB assembly can vary significantly based on the factors discussed, manufacturers can employ several strategies to optimize and potentially reduce the overall cost:

1. Design for Manufacturability (DFM)

Designing PCBs with manufacturability in mind can significantly reduce assembly costs. DFM principles involve optimizing the design for efficient assembly processes, minimizing component count, and ensuring compatibility with available manufacturing capabilities.

2. Component Optimization

Carefully selecting and optimizing the choice of electronic components can lead to cost savings. Manufacturers can explore alternative components, leverage volume discounts, and consider second-sourcing options to reduce component costs.

3. Process Optimization and Automation

Optimizing the assembly processes, implementing lean manufacturing principles, and increasing automation can help reduce labor costs, improve efficiency, and minimize waste, ultimately leading to cost savings.

4. Supplier and Vendor Negotiations

Negotiating favorable terms with suppliers and vendors for components, materials, and assembly services can help manufacturers achieve cost reductions through volume discounts, long-term agreements, or strategic partnerships.

5. Insourcing or Outsourcing Decisions

Manufacturers may consider insourcing or outsourcing PCB assembly operations based on their specific requirements, production volumes, and cost structures. Outsourcing to specialized contract manufacturers or leveraging low-cost regions can potentially reduce costs, while insourcing may be more cost-effective for high-volume or specialized assemblies.

6. Quality Management and Process Control

Implementing robust quality management systems and process control measures can help reduce defects, rework, and waste, ultimately leading to cost savings and improved efficiency.

Cost Comparison: In-House vs. Outsourced Assembly

One of the critical decisions manufacturers face is whether to assemble PCBs in-house or outsource the assembly process to a third-party contract manufacturer. Both approaches have their advantages and cost implications:

In-House Assembly

In-house PCB assembly allows manufacturers to maintain complete control over the process, ensuring quality and intellectual property protection. However, it also requires substantial upfront investments in specialized equipment, facilities, and skilled labor. In-house assembly may be more cost-effective for high-volume production or specialized assemblies, where the investment can be justified by the potential cost savings and efficiency gains.

Outsourced Assembly

Outsourcing PCB assembly to a third-party contract manufacturer can be a cost-effective solution, particularly for low to medium production volumes or for manufacturers without the necessary infrastructure or expertise. Contract manufacturers often benefit from economies of scale, advanced equipment, and specialized skills, which can translate into cost savings. However, outsourcing may also involve additional costs for shipping, logistics, and potential quality control challenges.

The decision to insource or outsource PCB assembly ultimately depends on factors such as production volume, complexity, cost structure, and the manufacturer’s core competencies and strategic goals.

Cost Comparison Table

To illustrate the potential cost differences between in-house and outsourced PCB assembly, consider the following hypothetical cost comparison table:

| Cost Category | In-House Assembly | Outsourced Assembly |

|---|---|---|

| Equipment and Facilities | High initial investment | Included in service fees |

| Labor | Skilled in-house workforce | Leveraged by CM’s workforce |

| Materials and Components | Direct procurement costs | Included in service fees |

| Quality Control | In-house inspection and testing | Shared responsibility with CM |

| Shipping and Logistics | Internal handling costs | Additional costs for shipping |

| Overhead and Operating Costs | Full overhead allocation | Partially included in service fees |

| Flexibility and Scalability | Limited by in-house capacity | Higher flexibility and scalability |

| Intellectual Property Protection | Higher control and protection | Potential risks and safeguards required |

Please note that this table is a simplified example, and actual costs may vary significantly based on the specific manufacturing requirements, production volumes, and other factors.

Frequently Asked Questions (FAQ)

1. What is the average cost of PCB assembly?

There is no single average cost for PCB assembly, as the cost can vary significantly depending on factors such as design complexity, component selection, production volume, and manufacturing processes. However, industry estimates suggest that the cost of PCB assembly can range from a few cents to several dollars per unit, depending on the complexity of the assembly.

2. Is it cheaper to assemble PCBs in-house or outsource to a contract manufacturer?

The decision to assemble PCBs in-house or outsource to a contract manufacturer depends on various factors, including production volume, complexity, and the manufacturer’s existing infrastructure and capabilities. In general, outsourcing may be more cost-effective for low to medium production volumes, while in-house assembly can be more economical for high-volume or specialized assemblies. However, a detailed cost analysis is necessary to determine the most cost-effective approach for a specific scenario.

3. How can I reduce the cost of PCB assembly?

There are several strategies to reduce the cost of PCB assembly, including:

- Optimizing the design for manufacturability (DFM)

- Carefully selecting cost-effective components and leveraging volume discounts

- Implementing lean manufacturing principles and process automation

- Negotiating favorable terms with suppliers and contract manufacturers

- Investing in quality management and process control to reduce defects and rework

4. Can the cost of PCB assembly be estimated accurately during the design phase?

While it is possible to estimate the cost of PCB assembly during the design phase, these estimates may not be highly accurate due to the numerous factors involved. Design-based cost estimation techniques, such as bottom-up costing or parametric cost estimation, can provide reasonable approximations, but actual costs may vary based on the manufacturing processes, component availability, and other variables.

5. How does the component packaging (e.g., SMD, BGA) affect the cost of PCB assembly?

The component packaging can significantly impact the cost of PCB assembly. Surface-mount components (SMDs), particularly those with smaller package sizes or advanced packages like ball grid arrays (BGAs), generally require more specialized assembly techniques and equipment, increasing the overall cost. Through-hole components, on the other hand, may be more cost-effective for certain applications but can be more labor-intensive to assemble.

No responses yet