Introduction to Flexible PCBs

Flexible printed circuit boards (PCBs) have revolutionized the electronics industry by offering a pliable alternative to traditional rigid PCBs. These versatile circuit boards can bend, fold, and twist without compromising their electrical integrity, making them ideal for compact devices and applications where space is limited. In this article, we will explore the world of flexible PCBs, their advantages, manufacturing process, applications, and future trends.

What are Flexible PCBs?

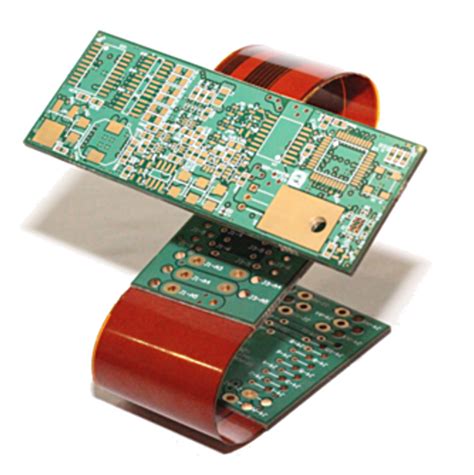

Flexible PCBs, also known as flex circuits, are thin, lightweight, and bendable circuit boards made from flexible plastic substrates such as polyimide or polyester. These substrates are laminated with conductive copper traces and can include additional layers for insulation, shielding, or adhesive backing. Flexible PCBs can be single-sided, double-sided, or multi-layered, depending on the complexity of the circuit design.

Advantages of Flexible PCBs

Flexible PCBs offer several advantages over traditional rigid PCBs:

- Space savings: Flexible PCBs can be bent, folded, or twisted to fit into tight spaces, making them ideal for compact devices like smartphones, wearables, and medical implants.

- Weight reduction: The thin, lightweight nature of flexible PCBs helps reduce the overall weight of electronic devices, which is particularly important for portable and aerospace applications.

- Improved reliability: Flexible PCBs can withstand vibrations, shocks, and extreme temperatures better than rigid PCBs, enhancing the reliability of electronic devices in harsh environments.

- Enhanced signal integrity: The shorter signal paths and reduced connector usage in flexible PCBs minimize signal loss and interference, improving overall signal integrity.

- Design flexibility: Flexible PCBs allow for creative and innovative product designs that would be impossible with rigid PCBs alone.

Manufacturing Process of Flexible PCBs

The manufacturing process of flexible PCBs involves several steps:

- Substrate preparation: The flexible substrate, typically polyimide or polyester, is cleaned and treated to ensure proper adhesion of the conductive layers.

- Conductive layer application: Copper foil is laminated onto the substrate using heat and pressure. The copper foil can be pre-treated with an adhesive or deposited using electroless plating.

- Circuit patterning: The desired circuit pattern is transferred onto the copper layer using photolithography. A photoresist is applied, exposed to UV light through a photomask, and developed to reveal the circuit pattern.

- Etching: The unwanted copper is removed using a chemical etching process, leaving behind the desired circuit traces.

- Insulation and protection: Additional layers of insulation, such as coverlay or solder mask, are applied to protect the circuit traces and prevent short circuits.

- Finishing: The flexible PCB may undergo further processing, such as surface finishing (e.g., ENIG, HASL), component assembly, or lamination with other layers or stiffeners.

Challenges in Flexible PCB Manufacturing

Manufacturing flexible PCBs presents some unique challenges compared to rigid PCBs:

- Material selection: Choosing the right substrate and conductive materials is crucial to ensure the desired flexibility, durability, and electrical performance of the final product.

- Dimensional stability: Flexible substrates can expand or contract during processing, making it challenging to maintain tight tolerances and registration between layers.

- Handling and processing: The thin and flexible nature of the substrates requires special handling and processing techniques to prevent damage or contamination.

- Reliability testing: Flexible PCBs must undergo rigorous testing to ensure they can withstand repeated bending, flexing, and environmental stresses without failure.

Applications of Flexible PCBs

Flexible PCBs find applications in various industries and products:

- Consumer electronics: Smartphones, tablets, laptops, and wearables heavily rely on flexible PCBs for their compact and lightweight designs.

- Medical devices: Implantable devices, diagnostic tools, and patient monitoring systems use flexible PCBs for their biocompatibility and ability to conform to body contours.

- Automotive electronics: Flexible PCBs are used in vehicle dashboard displays, sensors, and control modules, where space is limited, and reliability is critical.

- Aerospace and defense: Satellites, drones, and military equipment employ flexible PCBs for their lightweight, compact, and robust designs.

- Industrial automation: Flexible PCBs are used in robotics, machine vision systems, and sensor networks for their ability to fit into tight spaces and withstand harsh environments.

| Industry | Applications |

|---|---|

| Consumer electronics | Smartphones, tablets, laptops, wearables |

| Medical devices | Implantable devices, diagnostic tools, patient monitoring |

| Automotive electronics | Dashboard displays, sensors, control modules |

| Aerospace and defense | Satellites, drones, military equipment |

| Industrial automation | Robotics, machine vision systems, sensor networks |

Future Trends in Flexible PCB Technology

As the demand for compact, lightweight, and smart devices continues to grow, flexible PCB technology is expected to evolve:

- Increased functionality: Flexible PCBs will integrate more components and functions, such as sensors, antennas, and energy harvesting elements, to enable smarter and more connected devices.

- Advanced materials: New substrate materials and conductive inks with improved flexibility, durability, and electrical properties will be developed to enhance the performance of flexible PCBs.

- 3D printing: Additive manufacturing techniques, such as 3D printing, will be used to create complex, three-dimensional flexible PCB structures with embedded components and interconnects.

- Hybrid designs: Flexible PCBs will be combined with rigid PCBs and other electronic components to create hybrid designs that offer the best of both worlds in terms of functionality and flexibility.

- Sustainable manufacturing: Eco-friendly materials and processes will be adopted to reduce the environmental impact of flexible PCB manufacturing and support the growing demand for sustainable electronics.

Frequently Asked Questions (FAQ)

-

Q: Can flexible PCBs be repaired if damaged?

A: Repairing flexible PCBs can be challenging due to their thin and delicate nature. While minor repairs, such as replacing components or patching small cracks, may be possible, extensive damage often requires replacement of the entire board. -

Q: How do I choose the right substrate material for my flexible PCB?

A: The choice of substrate material depends on factors such as the desired flexibility, temperature resistance, dielectric properties, and cost. Polyimide is the most common substrate for high-performance applications, while polyester is often used for lower-cost and less demanding projects. Consulting with a flexible PCB manufacturer can help you select the most suitable material for your specific application. -

Q: Can flexible PCBs be used in high-temperature environments?

A: Yes, certain flexible PCB materials, such as polyimide, can withstand high temperatures up to 350°C. However, the maximum operating temperature depends on the specific substrate, adhesives, and components used. Proper material selection and design considerations are essential for high-temperature applications. -

Q: Are flexible PCBs more expensive than rigid PCBs?

A: In general, flexible PCBs are more expensive than rigid PCBs due to the specialized materials, processing techniques, and handling requirements involved. However, the cost difference can be justified by the unique benefits offered by flexible PCBs, such as space savings, weight reduction, and design flexibility. -

Q: How do I design a flexible PCB for optimal performance?

A: Designing a flexible PCB requires careful consideration of factors such as bend radius, conductor width and spacing, stiffener placement, and strain relief. Following best practices, such as using rounded corners, avoiding sharp bends, and providing adequate support for components, can help optimize the performance and reliability of your flexible PCB design. Working closely with an experienced flexible PCB manufacturer can ensure your design is optimized for manufacturability and functionality.

Conclusion

Flexible PCBs have become an essential component in the development of compact, lightweight, and innovative electronic devices. Their ability to bend, fold, and twist without compromising electrical performance has opened up new possibilities for product design and functionality. As the demand for smarter and more connected devices continues to grow, flexible PCB technology is expected to evolve, incorporating advanced materials, manufacturing processes, and design techniques.

By understanding the advantages, manufacturing process, applications, and future trends of flexible PCBs, engineers and designers can leverage this technology to create the next generation of electronic devices that are smaller, lighter, and more reliable than ever before. As the electronics industry continues to push the boundaries of what is possible, flexible PCBs will undoubtedly play a crucial role in shaping the future of technology.

No responses yet