Introduction to Gold Edge Connectors

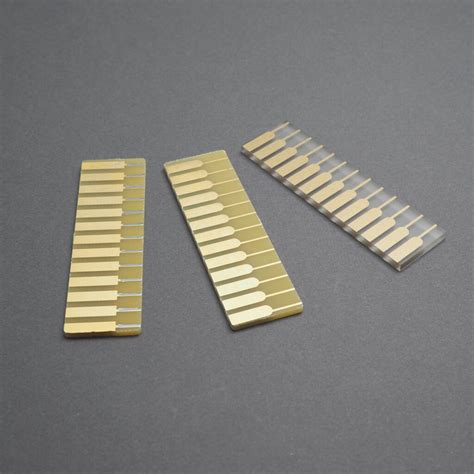

Gold edge connectors, also known as Gold Fingers or gold-plated edge connectors, are crucial components in various electronic devices and applications. These connectors are designed to provide reliable and efficient electrical connections between printed circuit boards (PCBs) and other components or systems. The gold surface on the edge of the connector offers several advantages, including enhanced conductivity, corrosion resistance, and durability.

In this comprehensive article, we will dive into the world of gold edge connectors, exploring their construction, applications, benefits, and considerations for designing and manufacturing devices that incorporate these essential components.

What are Gold Edge Connectors?

Gold edge connectors are specialized connectors that feature a series of conductive traces or pads plated with a thin layer of gold on the edge of a PCB. These traces are exposed and designed to mate with corresponding contacts in a connector socket or slot. The gold plating on the edge of the connector provides a highly conductive and corrosion-resistant surface, ensuring reliable electrical connections.

Construction of Gold Edge Connectors

The construction of gold edge connectors involves several key components and processes:

-

PCB Substrate: The base of the connector is a PCB, typically made from FR-4 or other high-quality materials. The PCB provides the necessary mechanical support and electrical insulation for the connector.

-

Conductive Traces: Copper traces are etched or printed onto the PCB, forming the conductive paths for electrical signals. These traces are carefully designed to ensure proper spacing, impedance matching, and signal integrity.

-

Gold Plating: The exposed edge of the PCB, where the conductive traces terminate, is plated with a thin layer of gold. The gold plating process involves depositing a layer of nickel as an undercoat, followed by a layer of gold. The thickness of the gold layer typically ranges from 0.05 to 0.5 micrometers, depending on the application requirements.

-

Solder Mask: A solder mask is applied to the PCB, covering the areas that do not require gold plating. The solder mask helps to protect the PCB and prevent accidental short circuits during the soldering process.

-

Surface Finish: In some cases, additional surface finishes may be applied to the gold edge connector to enhance its durability or compatibility with the mating connector. These finishes can include electroless nickel/immersion gold (ENIG), electroless nickel/electroless palladium/immersion gold (ENEPIG), or hard gold plating.

Types of Gold Edge Connectors

Gold edge connectors come in various types and configurations to suit different applications and requirements. Some common types include:

-

Card Edge Connectors: These connectors are designed to mate directly with the edge of a PCB, often used in computer peripherals, such as memory modules and expansion cards.

-

Board-to-Board Connectors: These connectors are used to establish connections between two PCBs, often in a parallel or perpendicular orientation. They are commonly found in mobile devices, consumer electronics, and automotive applications.

-

High-Speed Connectors: Gold edge connectors designed for high-speed applications, such as PCIe (Peripheral Component Interconnect Express) or SATA (Serial Advanced Technology Attachment), feature optimized trace geometry and impedance matching to maintain signal integrity at high frequencies.

-

Flexible Circuit Connectors: Gold edge connectors can also be used with flexible circuits, allowing for connections between rigid PCBs and flexible substrates. These connectors are commonly used in applications that require flexibility or moveable components.

Advantages of Gold Edge Connectors

Gold edge connectors offer several key advantages over other connector types:

High Conductivity

Gold is an excellent conductor of electricity, with a low contact resistance. The gold plating on the edge of the connector ensures reliable and efficient electrical connections, minimizing signal loss and power dissipation.

| Material | Electrical Conductivity (S/m) |

|---|---|

| Gold | 4.10 × 10^7 |

| Copper | 5.96 × 10^7 |

| Silver | 6.30 × 10^7 |

| Aluminum | 3.50 × 10^7 |

Table 1: Electrical conductivity of common connector materials

Corrosion Resistance

Gold is highly resistant to corrosion and oxidation, unlike other connector materials such as copper or tin. The gold plating on the edge of the connector provides a protective layer that prevents the formation of oxides or other contaminants that can degrade the electrical connection over time. This corrosion resistance is particularly important in harsh environments or applications exposed to moisture, chemicals, or extreme temperatures.

Durability

Gold edge connectors offer excellent durability and longevity, thanks to the hardness and wear resistance of gold. The gold plating helps to protect the underlying copper traces from mechanical wear and tear, ensuring reliable connections even after multiple mating cycles. This durability is crucial in applications that require frequent insertion and removal of the connector, such as in testing or field-replaceable units.

Low Insertion Force

Gold edge connectors typically require lower insertion forces compared to other connector types, such as pin-and-socket connectors. The smooth surface of the gold plating helps to reduce friction and minimize the force needed to mate the connector with its corresponding socket. This low insertion force is beneficial in applications where manual insertion is required or where delicate components are involved.

Compatibility with High-Speed Signals

Gold edge connectors are well-suited for high-speed signal transmission, thanks to their low contact resistance and ability to maintain signal integrity. The gold plating helps to minimize signal reflections and losses, ensuring clean and reliable signal transmission even at high frequencies. This compatibility with high-speed signals makes gold edge connectors a popular choice for applications such as high-speed digital interfaces, RF (radio frequency) systems, and high-bandwidth data transmission.

Applications of Gold Edge Connectors

Gold edge connectors find widespread use in a variety of industries and applications, including:

Consumer Electronics

Gold edge connectors are commonly used in consumer electronic devices, such as smartphones, tablets, laptops, and gaming consoles. They are used for board-to-board connections, display interfaces, and memory card slots, among other applications. The reliability and durability of gold edge connectors ensure stable and high-quality connections in these devices, which are subject to frequent use and handling.

Automotive Electronics

In the automotive industry, gold edge connectors are used in various electronic systems, such as infotainment systems, instrument clusters, and driver assistance systems. The corrosion resistance and durability of gold edge connectors make them suitable for the harsh environmental conditions encountered in automotive applications, including exposure to temperature extremes, vibrations, and moisture.

Industrial Automation

Gold edge connectors are used in industrial automation systems, such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), and industrial computers. These connectors provide reliable connections between control modules, I/O boards, and communication interfaces, ensuring the smooth operation of automated processes and equipment.

Medical Devices

In the medical device industry, gold edge connectors are used in a range of applications, including patient monitoring systems, diagnostic equipment, and surgical instruments. The high reliability and corrosion resistance of gold edge connectors are crucial in medical applications, where failure or degradation of connections can have serious consequences for patient safety and treatment outcomes.

Aerospace and Defense

Gold edge connectors are used in aerospace and defense applications, such as avionics systems, satellite communications, and military equipment. The durability and reliability of these connectors are essential in these mission-critical applications, where failure is not an option. Gold edge connectors can withstand the extreme environmental conditions encountered in aerospace and defense applications, including high altitudes, shock, and vibration.

Designing with Gold Edge Connectors

When designing devices or systems that incorporate gold edge connectors, several key considerations should be taken into account:

PCB Layout and Trace Design

The PCB layout and trace design are critical factors in ensuring the optimal performance of gold edge connectors. The traces should be carefully routed to maintain proper spacing, impedance matching, and signal integrity. The width and spacing of the traces should be designed to accommodate the specific requirements of the connector and the signals being transmitted.

Connector Selection

Choosing the right gold edge connector for a given application involves considering several factors, such as the number of contacts, pitch (spacing between contacts), mating cycles, and environmental requirements. The connector should be selected based on the specific needs of the application, taking into account factors such as signal speed, power requirements, and mechanical constraints.

Mating Connector Compatibility

When designing a device with a gold edge connector, it is important to ensure compatibility with the mating connector or socket. The mating connector should have the correct number of contacts, pitch, and orientation to properly mate with the gold edge connector. Mechanical tolerances and alignment should also be considered to ensure reliable and consistent mating.

Signal Integrity Analysis

For high-speed applications, signal integrity analysis is crucial to ensure that the gold edge connector and the associated PCB traces can maintain the required signal quality. Simulation tools and modeling techniques can be used to analyze the signal behavior and optimize the design for maximum performance. Factors such as crosstalk, reflections, and losses should be carefully evaluated and mitigated.

Manufacturing Considerations

When manufacturing devices with gold edge connectors, several considerations should be taken into account to ensure high quality and reliability:

-

Plating Process: The gold plating process should be carefully controlled to achieve the desired thickness and uniformity. The plating bath composition, temperature, and current density should be optimized to ensure consistent and reliable plating results.

-

Solder Mask Application: The solder mask should be applied accurately and consistently to ensure that the gold-plated areas are properly exposed and protected. Any defects or inconsistencies in the solder mask can lead to issues with connector mating or signal integrity.

-

Inspection and Testing: Rigorous inspection and testing procedures should be implemented to ensure that the gold edge connectors meet the required specifications and performance criteria. Visual inspection, continuity testing, and mating cycle testing are common methods used to verify the quality and reliability of the connectors.

Advantages of Gold Edge Connectors Over Other Connector Types

Gold edge connectors offer several advantages over other connector types, such as pin-and-socket connectors or spring-loaded contacts:

-

Simplified Assembly: Gold edge connectors eliminate the need for separate connector housings or shells, simplifying the assembly process and reducing the overall component count. The connectors can be directly integrated into the PCB, saving space and reducing assembly time and costs.

-

Reduced Contact Resistance: The gold plating on the edge of the connector provides a low contact resistance, ensuring reliable and efficient electrical connections. This low contact resistance is particularly important in applications with low-level signals or high-speed data transmission.

-

Improved Signal Integrity: Gold edge connectors offer improved signal integrity compared to other connector types, thanks to their ability to maintain consistent contact pressure and minimize signal reflections. The smooth surface of the gold plating helps to reduce noise and ensure clean signal transmission.

-

Enhanced Durability: The hardness and wear resistance of gold plating make gold edge connectors more durable than other connector types. They can withstand multiple mating cycles without significant degradation in performance, making them suitable for applications that require frequent insertion and removal.

-

Cost-Effectiveness: Although gold is a relatively expensive material, the cost of gold edge connectors is often offset by their simplified assembly, reliability, and durability. The elimination of separate connector components and the reduced need for maintenance or replacement can result in overall cost savings in the long run.

Frequently Asked Questions (FAQ)

Q1: What is the typical thickness of gold plating on gold edge connectors?

A1: The thickness of the gold plating on gold edge connectors typically ranges from 0.05 to 0.5 micrometers, depending on the specific application requirements. Thicker gold plating is often used in applications that demand higher durability or corrosion resistance.

Q2: Can gold edge connectors be used in high-temperature environments?

A2: Yes, gold edge connectors can be used in high-temperature environments, thanks to the stability and corrosion resistance of gold. However, the maximum operating temperature will depend on the specific connector design and the materials used in the PCB substrate and other components. It is important to consult the connector manufacturer’s specifications to ensure suitability for high-temperature applications.

Q3: How do I choose the right pitch for a gold edge connector?

A3: The choice of pitch (spacing between contacts) for a gold edge connector depends on several factors, including the signal requirements, PCB space constraints, and mating connector compatibility. Smaller pitches (e.g., 0.5 mm or 0.635 mm) are often used in applications with high contact density or limited PCB space. Larger pitches (e.g., 1.27 mm or 2.54 mm) are used in applications with lower contact density or higher current requirements. It is important to consider the specific requirements of the application and consult the connector manufacturer’s recommendations when selecting the appropriate pitch.

Q4: Can gold edge connectors be repaired or reworked?

A4: In most cases, gold edge connectors cannot be easily repaired or reworked due to their integrated nature with the PCB. If a connector is damaged or defective, it is often necessary to replace the entire PCB Assembly. However, in some cases, localized repair or rework may be possible using specialized techniques, such as gold plating restoration or selective surface treatment. It is important to consult with a qualified repair or rework service provider to determine the feasibility and cost-effectiveness of such repairs.

Q5: Are there any alternatives to gold plating for edge connectors?

A5: While gold plating is the most common and preferred choice for edge connectors, there are some alternatives available, such as palladium or silver plating. These alternative plating materials can offer some of the benefits of gold, such as low contact resistance and corrosion resistance, but may have limitations in terms of durability or cost-effectiveness. In some cases, other connector types, such as press-fit or soldered connectors, may be used instead of edge connectors, depending on the specific application requirements and constraints.

Conclusion

Gold edge connectors are essential components in a wide range of electronic devices and applications, offering reliable, durable, and high-performance electrical connections. The gold plating on the edge of the connector provides numerous benefits, including high conductivity, corrosion resistance, durability, and compatibility with high-speed signals.

When designing devices with gold edge connectors, careful consideration should be given to PCB layout, trace design, connector selection, mating connector compatibility, and signal integrity analysis. Manufacturing processes, such as plating, solder mask application, and inspection, should also be optimized to ensure the highest quality and reliability.

As technology continues to advance, the demand for gold edge connectors is expected to grow, driven by the increasing complexity and performance requirements of electronic devices. By understanding the principles, advantages, and considerations associated with gold edge connectors, engineers and designers can develop innovative and reliable products that meet the evolving needs of the market.

No responses yet