What are Gerber and NC Drill files?

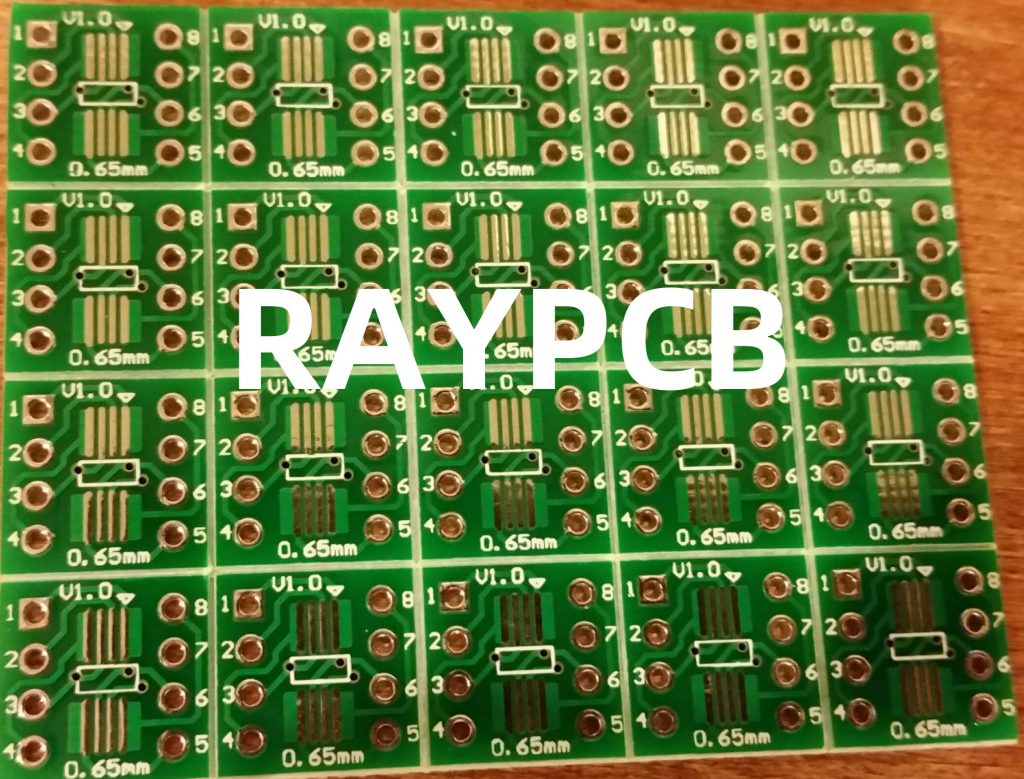

Gerber files, also known as RS-274X format, are the industry standard for describing the layout of a PCB. They contain information about the copper layers, solder mask, silkscreen, and other aspects of the PCB design. Each layer of the PCB is represented by a separate Gerber file, and these files are used by PCB manufacturers to create the physical boards.

NC Drill files, on the other hand, contain information about the holes that need to be drilled in the PCB. These holes are used for mounting components, creating vias, and other purposes. The NC Drill file specifies the size, location, and type of each hole to be drilled.

Why convert PDF to Gerber and NC Drill formats?

PDF files are widely used for sharing and printing documents, but they are not suitable for PCB manufacturing. PCB fabrication equipment requires specific file formats, such as Gerber and NC Drill, to interpret the design data correctly. Converting PDF to Gerber and NC Drill formats ensures that the PCB manufacturer has all the necessary information to produce the board accurately.

There are several reasons why you might need to convert PDF to Gerber and NC Drill formats:

- PCB design software compatibility: Some PCB design software may not have the ability to export directly to Gerber and NC Drill formats. In such cases, designers may export their designs as PDF files and then convert them to the required formats.

- Design review and collaboration: PDF files are often used for sharing and reviewing PCB designs with team members or clients. However, when it comes to manufacturing, the PCB fabricator will require Gerber and NC Drill files.

- Legacy designs: Some older PCB designs may only be available in PDF format. Converting these files to Gerber and NC Drill formats allows for the re-manufacture of legacy boards.

Methods for converting PDF to Gerber and NC Drill formats

There are several methods for converting PDF to Gerber and NC Drill formats, each with its advantages and limitations. The choice of method will depend on the complexity of the design, the available software tools, and the user’s technical expertise.

1. Using PCB design software

Most modern PCB design software, such as Altium Designer, KiCad, and Eagle, have the ability to import PDF files and export them as Gerber and NC Drill files. This method is the most straightforward and reliable, as the software is specifically designed to handle PCB Layouts.

To convert PDF to Gerber and NC Drill formats using PCB design software:

- Import the PDF file into the PCB design software.

- Ensure that the imported design is correctly aligned and scaled.

- Export the design as Gerber and NC Drill files, following the software’s export settings and guidelines.

Advantages:

– Accurate and reliable conversion

– Ability to make changes to the design before exporting

– Familiar interface for PCB designers

Limitations:

– Requires access to PCB design software

– May involve a learning curve for users unfamiliar with the software

2. Using online conversion tools

Several online tools offer PDF to Gerber and NC Drill conversion services. These tools are generally easy to use and require no additional software installation. Some popular online conversion tools include PCB Visualizer, CAM Expert, and FilesConvert.

To convert PDF to Gerber and NC Drill formats using online tools:

- Upload the PDF file to the online conversion tool.

- Select the desired output formats (Gerber and NC Drill).

- Choose the appropriate conversion settings, such as layer naming and file resolution.

- Download the converted files.

Advantages:

– Easy to use

– No software installation required

– Often free or low-cost

Limitations:

– Limited control over conversion settings

– Dependency on internet connectivity

– Potential security concerns when uploading sensitive design data

3. Using standalone conversion software

There are standalone software applications dedicated to converting PDF to Gerber and NC Drill formats. These tools often provide more advanced features and settings compared to online conversion tools. Some examples of standalone conversion software include PCB Converter and ViewMate.

To convert PDF to Gerber and NC Drill formats using standalone conversion software:

- Install the conversion software on your computer.

- Import the PDF file into the software.

- Adjust the conversion settings, such as layer mapping and file resolution.

- Export the design as Gerber and NC Drill files.

Advantages:

– Advanced conversion settings and features

– No internet connectivity required

– Suitable for handling large or complex designs

Limitations:

– Requires software installation and licensing

– May have a steeper learning curve compared to online tools

Best practices for PDF-to-Gerber Conversion

To ensure a smooth and accurate conversion from PDF to Gerber and NC Drill formats, follow these best practices:

- Ensure PDF quality: Make sure that the PDF file is of high quality and contains all the necessary information for PCB fabrication. The PDF should be created from the original PCB design software, rather than scanned or converted from other formats.

- Use appropriate layer naming: When converting PDF to Gerber, ensure that the layer names are meaningful and consistent with the PCB manufacturing standards. This helps the fabricator understand the purpose of each layer and avoid confusion.

- Check file resolution: Gerber and NC Drill files should have an appropriate resolution to ensure accurate PCB fabrication. The standard resolution for Gerber files is 2.4 or 2.5, while NC Drill files typically use 2.4.

- Verify the converted files: After converting PDF to Gerber and NC Drill formats, it is essential to verify the output files. Use a Gerber Viewer to check for any errors, missing features, or incorrect layer mappings. Compare the converted files with the original PDF to ensure accuracy.

- Communicate with the PCB manufacturer: When sending Gerber and NC Drill files to the PCB manufacturer, provide clear instructions and specifications. Include information about the PCB materials, thickness, surface finish, and any special requirements. Maintain open communication with the manufacturer to address any concerns or questions.

FAQ

- Can I convert PDF to Gerber and NC Drill formats for free?

Yes, there are several online tools and Open-source PCB design software that allow you to convert PDF to Gerber and NC Drill formats for free. However, keep in mind that free tools may have limitations in terms of features or file size. - What if my PDF file contains multiple pages?

If your PDF file contains multiple pages, you will need to convert each page separately to Gerber and NC Drill formats. Ensure that each page represents a different layer of the PCB design and that the layer naming is consistent across all pages. - Can I convert Gerber and NC Drill files back to PDF?

Yes, it is possible to convert Gerber and NC Drill files back to PDF format using PCB design software or online conversion tools. This can be useful for sharing the design with team members or clients who may not have access to PCB design software. - What should I do if the converted Gerber and NC Drill files have errors?

If you notice errors in the converted Gerber and NC Drill files, first verify that the original PDF file is correct and contains all the necessary information. If the issue persists, try using a different conversion method or tool. If the errors are related to layer mapping or file resolution, adjust the conversion settings accordingly. - How can I ensure that my PCB design is manufacturable?

To ensure that your PCB design is manufacturable, follow the design guidelines provided by your chosen PCB manufacturer. These guidelines typically include information about minimum trace widths, clearances, drill sizes, and other design rules. Additionally, consider using a design for manufacturability (DFM) tool to check your design for potential issues before sending it for fabrication.

Conclusion

Converting PDF to Gerber and NC Drill formats is a critical step in the PCB manufacturing process. By understanding the various methods and best practices for PDF-to-Gerber conversion, PCB designers can ensure that their designs are accurately translated into the formats required for fabrication. Whether using PCB design software, online conversion tools, or standalone applications, it is essential to verify the converted files and communicate clearly with the PCB manufacturer to achieve the best results.

As the electronics industry continues to evolve, the importance of efficient and accurate PCB design and manufacturing processes will only grow. By mastering the art of PDF-to-Gerber conversion, PCB designers can streamline their workflows, reduce errors, and ultimately bring their innovative ideas to life.

| Method | Advantages | Limitations |

|---|---|---|

| Using PCB design software | – Accurate and reliable conversion | – Requires access to PCB design software |

| – Ability to make changes to the design before exporting | – May involve a learning curve for users unfamiliar with the software | |

| Using online conversion tools | – Easy to use | – Limited control over conversion settings |

| – No software installation required | – Dependency on internet connectivity | |

| – Often free or low-cost | – Potential security concerns when uploading sensitive design data | |

| Using standalone conversion software | – Advanced conversion settings and features | – Requires software installation and licensing |

| – No internet connectivity required | – May have a steeper learning curve compared to online tools | |

| – Suitable for handling large or complex designs |

By following the best practices and choosing the most suitable conversion method for their needs, PCB designers can ensure a smooth and accurate transition from PDF to Gerber and NC Drill formats, ultimately leading to successful PCB manufacturing and bringing their Electronic Designs to life.

No responses yet