Introduction to Lithium Battery PCBs in Electric Vehicles

The rise of electric vehicles (EVs) has revolutionized the automotive industry, offering a more environmentally friendly and efficient alternative to traditional gasoline-powered cars. At the heart of every EV lies a sophisticated lithium battery system, which relies on advanced Printed Circuit Boards (PCBs) to manage and control its operation. In this comprehensive guide, we will delve into the world of lithium battery PCBs for electric cars, exploring their key components, design considerations, and the crucial role they play in powering the future of transportation.

The Significance of Lithium Battery PCBs in EVs

Lithium battery PCBs are essential components in electric vehicles, as they provide the necessary control and monitoring functions for the battery system. These PCBs ensure that the lithium batteries operate safely, efficiently, and reliably, enabling EVs to deliver optimal performance and range. Some of the critical functions of lithium battery PCBs include:

- Battery management: Monitoring and balancing individual cell voltages, currents, and temperatures to prevent overcharging, undercharging, and thermal runaway.

- Power distribution: Regulating and distributing power from the battery pack to various vehicle systems, such as the electric motor, onboard charger, and auxiliary components.

- Communication: Facilitating data exchange between the battery management system (BMS) and other vehicle control units, such as the motor controller and charging system.

- Fault detection and protection: Continuously monitoring the battery system for potential faults and implementing safety measures to prevent damage or hazardous conditions.

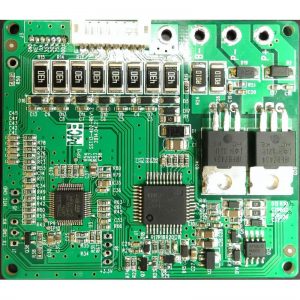

Key Components of Lithium Battery PCBs

To effectively manage and control the lithium battery system in an electric vehicle, the PCB must incorporate several key components. These components work together to ensure optimal battery performance, safety, and longevity.

Battery Management System (BMS) Integrated Circuits (ICs)

BMS ICs are the brain of the lithium battery PCB, responsible for monitoring and controlling the battery pack’s operation. These specialized chips typically feature built-in functions such as cell voltage monitoring, cell balancing, temperature sensing, and fault detection. Some popular BMS ICs used in EV applications include:

| Manufacturer | IC Model | Key Features |

|---|---|---|

| Texas Instruments | BQ76PL455A-Q1 | Supports up to 16 cells, integrated cell balancing, ISO 26262 compliant |

| NXP Semiconductors | MC33771B | Supports up to 14 cells, integrated cell balancing, SPI communication |

| Analog Devices | AD8280 | Supports up to 6 cells, high-voltage tolerance, daisy-chainable |

Current Sensing Resistors

Current sensing resistors play a crucial role in monitoring the flow of current in and out of the battery pack. These high-precision, low-resistance components enable the BMS to accurately measure current levels, which is essential for state-of-charge (SoC) estimation, power calculations, and fault detection. Some factors to consider when selecting current sensing resistors for EV applications include:

- Low resistance value (typically in the milliohm range) to minimize power loss

- High power rating to handle peak currents during acceleration or regenerative braking

- Low temperature coefficient of resistance (TCR) for accurate measurements across a wide temperature range

- Surface mount device (SMD) packaging for automated assembly and compact PCB Design

Temperature Sensors

Monitoring the temperature of individual battery cells and the overall pack is critical for ensuring safe and efficient operation. Lithium batteries are sensitive to temperature, and excessive heat can lead to degradation, capacity loss, or even thermal runaway. Temperature sensors, such as thermistors or resistance temperature detectors (RTDs), are strategically placed on the PCB to provide real-time temperature data to the BMS. This information is used to control cooling systems, adjust charging/discharging rates, and trigger safety shutdowns if necessary.

Isolation Components

In high-voltage EV battery systems, electrical isolation between the battery pack and the vehicle’s low-voltage circuitry is crucial for safety and compliance with automotive standards. Isolation components, such as optocouplers, isolators, and isolated gate drivers, are used on the lithium battery PCB to provide galvanic isolation between the high-voltage and low-voltage domains. These components ensure that any faults or transients in the battery system do not propagate to other vehicle systems, protecting both the electronics and the occupants.

PCB Design Considerations for EV Lithium Battery Systems

Designing a lithium battery PCB for an electric vehicle requires careful consideration of various factors to ensure optimal performance, reliability, and safety. Some key design considerations include:

High-Voltage Layout

EV battery packs typically operate at voltages ranging from 300V to 800V, depending on the vehicle’s specifications. Designing a PCB for high-voltage operation requires special attention to creepage and clearance distances, as well as the selection of appropriate materials and components. The PCB Layout must ensure adequate spacing between high-voltage traces and other components, as well as provide proper insulation and shielding to prevent arcing or leakage currents.

Thermal Management

Effective thermal management is essential for maintaining the performance and longevity of lithium batteries in EVs. The lithium battery PCB must be designed to facilitate efficient heat dissipation, both from the battery cells and the PCB Components themselves. This can be achieved through the use of thermal interface materials (TIMs), heat sinks, and strategic component placement. The PCB layout should also allow for adequate airflow or liquid cooling, depending on the vehicle’s thermal management system.

EMI/EMC Considerations

Electric vehicles are subject to stringent electromagnetic compatibility (EMC) requirements to ensure they do not interfere with other electronic systems or be affected by external electromagnetic interference (EMI). The lithium battery PCB must be designed to minimize EMI emissions and susceptibility, through techniques such as proper grounding, shielding, and filtering. The use of multi-layer PCBs with dedicated ground planes and the selection of components with low EMI characteristics can help meet these requirements.

Modularity and Scalability

EV battery packs are often designed as modular systems, consisting of multiple sub-packs or modules connected in series or parallel to achieve the desired voltage and capacity. The lithium battery PCB should be designed with modularity and scalability in mind, allowing for easy integration of multiple PCBs into a larger battery system. This can be achieved through the use of standardized connectors, communication protocols, and form factors, enabling flexible configuration and future upgrades.

Testing and Validation of Lithium Battery PCBs

Rigorous testing and validation are essential to ensure that lithium battery PCBs meet the demanding requirements of electric vehicle applications. Some key testing and validation procedures include:

Functional Testing

Functional testing verifies that the lithium battery PCB performs all its intended functions, such as cell voltage monitoring, cell balancing, current sensing, and temperature monitoring. This can be done through automated test equipment (ATE) that simulates various operating conditions and checks for proper functionality and accuracy.

Environmental Testing

EV battery systems must be able to withstand harsh environmental conditions, including extreme temperatures, vibration, and shock. Environmental testing exposes the lithium battery PCB to these conditions to ensure it remains functional and reliable. This can include thermal cycling, vibration testing, and mechanical shock testing, among others.

Safety Testing

Given the high voltages and energy densities involved in EV battery systems, safety is of paramount importance. Safety testing ensures that the lithium battery PCB incorporates proper protection mechanisms and fail-safe features to prevent hazardous conditions such as overcharging, overheating, or short circuits. This can include over-voltage protection (OVP) testing, over-current protection (OCP) testing, and fault injection testing.

EMC Testing

To ensure compliance with automotive EMC standards, the lithium battery PCB must undergo extensive EMC testing. This includes both emissions testing to measure the PCB’s electromagnetic emissions and susceptibility testing to evaluate its immunity to external EMI. EMC testing is typically performed in specialized anechoic chambers or shielded enclosures to provide a controlled environment.

Future Trends and Innovations in Lithium Battery PCBs for EVs

As electric vehicles continue to evolve and gain widespread adoption, lithium battery PCBs will also undergo significant advancements to keep pace with the industry’s demands. Some future trends and innovations to watch for include:

Wireless BMS

Wireless battery management systems (BMS) are an emerging trend in EV battery design, offering several advantages over traditional wired systems. Wireless BMS eliminates the need for complex wiring harnesses, reducing weight, cost, and assembly time. It also enables more flexible battery pack configurations and simplifies maintenance and replacement procedures. As wireless technology continues to mature, we can expect to see more EV manufacturers adopting wireless BMS solutions.

Integration of Advanced Sensors

The integration of advanced sensors, such as fiber optic sensors or ultrasonic sensors, can provide more accurate and reliable monitoring of battery cell conditions. These sensors can measure parameters such as strain, pressure, or electrolyte concentration, enabling early detection of potential issues and more precise control of the battery system. As sensor technologies continue to evolve, we can expect to see their increased adoption in lithium battery PCBs for EVs.

Solid-State Battery Integration

Solid-state batteries are a promising next-generation battery technology that offers higher energy density, faster charging, and improved safety compared to conventional lithium-ion batteries. As solid-state batteries become commercially viable, lithium battery PCBs will need to adapt to their unique characteristics and requirements. This may involve the development of new BMS architectures, materials, and manufacturing processes optimized for solid-state battery integration.

Frequently Asked Questions (FAQ)

- What is the typical voltage range for EV lithium battery packs?

EV lithium battery packs typically operate at voltages ranging from 300V to 800V, depending on the vehicle’s specifications and performance requirements. - Why is cell balancing important in lithium battery PCBs?

Cell balancing is crucial for ensuring that all cells in a battery pack are at the same voltage level, which maximizes the pack’s overall capacity and prevents individual cells from being overcharged or undercharged. This helps to extend the battery’s lifespan and maintain its performance over time. - What are the key safety features incorporated in lithium battery PCBs for EVs?

Lithium battery PCBs for EVs incorporate various safety features, such as over-voltage protection (OVP), over-current protection (OCP), and temperature monitoring. These features help to prevent hazardous conditions like overcharging, overheating, or short circuits, ensuring the safe operation of the battery system. - How do lithium battery PCBs communicate with other vehicle systems?

Lithium battery PCBs communicate with other vehicle systems, such as the motor controller and charging system, through various communication protocols like CAN (Controller Area Network), LIN (Local Interconnect Network), or Ethernet. These protocols enable the exchange of data and control signals between the battery management system and other vehicle components. - What are the benefits of using a wireless BMS in EV lithium battery systems?

Wireless battery management systems offer several advantages, including reduced weight, cost, and assembly time, as they eliminate the need for complex wiring harnesses. They also enable more flexible battery pack configurations and simplify maintenance and replacement procedures, making them an attractive option for future EV designs.

Conclusion

Lithium battery PCBs play a critical role in the development and advancement of electric vehicles, enabling the safe, efficient, and reliable operation of high-voltage battery systems. By understanding the key components, design considerations, and testing requirements of these PCBs, engineers and manufacturers can continue to push the boundaries of EV performance and adoption.

As the demand for electric vehicles grows, innovations in lithium battery PCB technology, such as wireless BMS, advanced sensors, and solid-state battery integration, will drive further improvements in range, charging speed, and safety. By staying at the forefront of these developments, the automotive industry can accelerate the transition to a more sustainable and electrified future.

No responses yet