PCB Material Selection

The choice of PCB material is critical as it affects the board’s electrical, mechanical, and thermal properties. The most common PCB materials include:

| Material | Description | Dielectric Constant | Dissipation Factor | Tg (°C) |

|---|---|---|---|---|

| FR-4 | Fiberglass-reinforced epoxy laminate | 4.2-4.5 | 0.02 | 130-140 |

| Rogers 4003C | Hydrocarbon ceramic laminate | 3.38 | 0.0027 | >280 |

| Polyimide | High-temperature resistant polymer | 3.5 | 0.002 | >250 |

| PTFE | Polytetrafluoroethylene (Teflon) | 2.1 | 0.0004 | 327 |

When selecting a PCB material, consider the following factors:

– Dielectric constant: Affects signal propagation speed and impedance

– Dissipation factor: Determines the material’s loss tangent and signal attenuation

– Glass transition temperature (Tg): Indicates the material’s thermal stability

High-Frequency Material Considerations

For high-frequency applications, such as RF and microwave circuits, low-loss materials with stable dielectric constants are essential. Rogers 4003C and PTFE are popular choices for these applications due to their excellent electrical properties and low dissipation factors.

PCB Layer Stack-up

The PCB layer stack-up refers to the arrangement of conductive and insulating layers within the board. A well-designed stack-up ensures proper signal integrity, power distribution, and EMI control. Key considerations include:

Number of Layers

The number of layers in a PCB depends on the complexity of the circuit and the required functionality. Common layer counts include:

| Layers | Typical Applications |

|---|---|

| 1 | Simple circuits, single-sided boards |

| 2 | Double-sided boards, low-complexity designs |

| 4 | Medium-complexity designs, mixed-signal circuits |

| 6+ | High-complexity designs, dense routing, high-speed digital |

Layer Arrangement

A typical 4-layer PCB Stack-up might include:

- Top Layer: Signal routing, components

- Inner Layer 1: Ground plane

- Inner Layer 2: Power plane

- Bottom Layer: Signal routing, components

Proper layer arrangement minimizes crosstalk, improves signal integrity, and provides effective power distribution and grounding.

PCB Trace Width and Spacing

Trace width and spacing are critical parameters that affect signal integrity, current-carrying capacity, and manufacturability.

Trace Width

The trace width is determined by several factors, including:

– Current-carrying requirements: Use IPC-2152 standards to calculate minimum trace widths based on current, temperature rise, and copper thickness.

– Characteristic impedance: Control trace width and dielectric thickness to achieve desired characteristic impedance for high-speed signals.

– Manufacturability: Ensure trace widths are compatible with PCB fabrication capabilities.

Trace Spacing

Trace spacing is governed by:

– Voltage breakdown: Maintain sufficient clearance between traces to prevent electrical breakdown, especially for high-voltage applications.

– Signal integrity: Increase spacing between sensitive signals to minimize crosstalk and electromagnetic interference (EMI).

– Manufacturing constraints: Adhere to minimum spacing requirements based on PCB fabrication capabilities and design rules.

PCB Hole Sizes

PCB holes are used for component leads, vias, and mounting. Proper hole sizing is essential for manufacturability and reliability.

Drilled Hole Size

The drilled hole size is determined by the component lead or via diameter, plus an allowance for plating thickness. Common hole sizes range from 0.2 mm to 6 mm, depending on the application.

Plated Through-Hole (PTH) vs. Non-Plated Through-Hole (NPTH)

- PTH: Used for electrical connections between layers, component mounting, and heat dissipation. The hole walls are plated with conductive material, typically copper.

- NPTH: Used for mechanical purposes, such as mounting or alignment. The hole walls are not plated.

Via Types

Vias are used to connect traces between layers in a PCB. Common via types include:

| Via Type | Description |

|---|---|

| Through | Connects all layers, from top to bottom |

| Blind | Connects an outer layer to an inner layer, but not all layers |

| Buried | Connects inner layers, not visible from the outer layers |

| Micro | Small-diameter vias for high-density designs |

Select via types based on the PCB design requirements, layer stack-up, and manufacturing capabilities.

PCB Surface Finish

The PCB surface finish protects exposed copper and enhances solderability. Common surface finishes include:

| Finish | Description | Shelf Life | Solderability | Cost |

|---|---|---|---|---|

| HASL | Hot Air Solder Leveling | 12 months | Good | Low |

| ENIG | Electroless Nickel Immersion Gold | 12 months | Excellent | High |

| OSP | Organic Solderability Preservative | 6 months | Good | Low |

| Immersion Tin | Thin layer of tin over copper | 12 months | Good | Medium |

| Immersion Silver | Thin layer of silver over copper | 6 months | Excellent | Medium |

Choose a surface finish based on the application requirements, component types, and manufacturing process.

PCB Solder Mask and Silkscreen

Solder mask and silkscreen are essential for PCB Assembly and identification.

Solder Mask

Solder mask is a polymer coating applied to the PCB surface, serving several purposes:

– Protects traces from oxidation and contamination

– Prevents solder bridging between closely spaced pads

– Provides electrical insulation between components

Common solder mask colors include green, blue, red, and black.

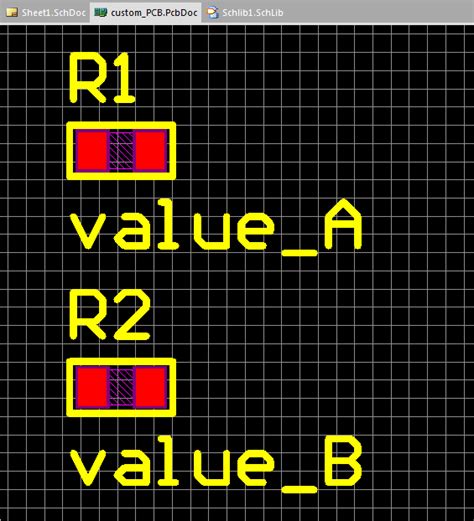

Silkscreen

Silkscreen is a printed layer on the PCB surface used for component identification and assembly instructions. It typically includes:

– Component outlines and reference designators

– Polarity indicators

– Test points and fiducial markers

– Company logos and product information

Silkscreen is usually white, but other colors may be used for improved contrast or aesthetics.

PCB Assembly Considerations

When designing a PCB, it is essential to consider the assembly process to ensure manufacturability and minimize defects.

Component Placement

- Group components by type and height to facilitate automated assembly

- Provide adequate spacing between components for soldering and inspection

- Orient components in a consistent direction to simplify assembly and reduce errors

Soldering

- Select appropriate solder paste and stencil thickness based on component pitch and pad size

- Use thermal relief pads for PTH components to prevent solder wicking

- Ensure proper solder mask clearance around pads to prevent solder bridging

Testability

- Include test points for critical signals and power supplies

- Provide fiducial markers for automated optical inspection (AOI) and pick-and-place machines

- Consider boundary scan testing for complex digital designs

FAQ

1. What is the difference between a 2-layer and a 4-layer PCB?

A 2-layer PCB consists of a top and bottom layer, with components and traces on both sides. A 4-layer PCB adds two inner layers, typically used for power and ground planes. 4-layer PCBs offer better signal integrity, EMI reduction, and more routing space compared to 2-layer boards.

2. How do I select the appropriate trace width for my PCB design?

To select the appropriate trace width, consider the following factors:

– Current-carrying requirements: Use IPC-2152 standards to calculate minimum trace widths based on the expected current, allowable temperature rise, and copper thickness.

– Characteristic impedance: For high-speed signals, control the trace width and dielectric thickness to achieve the desired characteristic impedance.

– Manufacturability: Ensure that the chosen trace widths are compatible with the capabilities of your PCB fabrication partner.

3. What is the purpose of solder mask on a PCB?

Solder mask serves several purposes on a PCB:

– Protection: It protects the copper traces from oxidation and contamination, extending the board’s life.

– Insulation: Solder mask provides electrical insulation between components and traces, preventing short circuits.

– Solder control: It prevents solder bridging between closely spaced pads during the soldering process.

4. How do I choose the right surface finish for my PCB?

When selecting a PCB surface finish, consider the following factors:

– Solderability: Some finishes, like ENIG and Immersion Silver, offer excellent solderability compared to others.

– Shelf life: OSP and Immersion Silver have shorter shelf lives compared to HASL, ENIG, and Immersion Tin.

– Cost: HASL and OSP are generally lower-cost options, while ENIG is more expensive.

– Application: Certain finishes may be more suitable for specific applications, such as high-temperature or high-reliability environments.

5. What are the benefits of using blind and buried vias in a PCB design?

Blind and buried vias offer several advantages in PCB design:

– Space savings: By connecting only the necessary layers, blind and buried vias free up valuable board space for routing and component placement.

– Improved signal integrity: Shorter via lengths reduce signal reflections and improve overall signal integrity.

– Enhanced design flexibility: Blind and buried vias allow for more complex routing and layer stack-up configurations.

– Reduced EMI: By minimizing the number of vias that span the entire board thickness, blind and buried vias can help reduce electromagnetic interference.

In conclusion, understanding and properly selecting basic PCB Parameters is crucial for designing reliable, manufacturable, and high-performance printed circuit boards. By considering factors such as material selection, layer stack-up, trace width and spacing, hole sizes, surface finish, and assembly requirements, designers can create PCBs that meet the specific needs of their applications while minimizing potential issues and costs.

No responses yet