Introduction to Automotive PCBs

Printed Circuit Boards (PCBs) are the backbone of modern electronics, and the automotive industry is no exception. As vehicles become increasingly sophisticated, with advanced driver assistance systems (ADAS), infotainment, and electrification, the demand for high-quality, reliable, and durable PCBs has never been greater. In this comprehensive article, we will explore the latest updates and trends in automotive PCBs as of 2024.

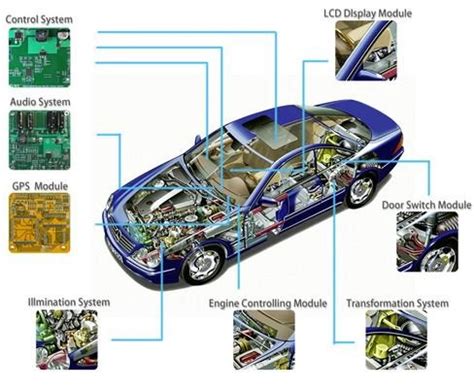

The Role of PCBs in the Automotive Industry

PCBs play a crucial role in the automotive industry, enabling the functionality of various electronic systems within a vehicle. Some of the key applications of automotive PCBs include:

- Engine Control Units (ECUs)

- Transmission Control Modules (TCMs)

- Body Control Modules (BCMs)

- Infotainment Systems

- Advanced Driver Assistance Systems (ADAS)

- Battery Management Systems (BMS) for electric vehicles

As the automotive industry continues to evolve, the demand for more advanced and reliable PCBs is expected to grow significantly.

Automotive PCB Market Trends and Forecasts

Market Size and Growth

According to recent market research, the global automotive PCB market is expected to reach USD 14.5 billion by 2024, growing at a CAGR of 6.8% during the forecast period (2019-2024). The growth is primarily driven by the increasing demand for advanced electronic systems in vehicles, the rise of electric and hybrid vehicles, and the growing adoption of ADAS.

| Year | Market Size (USD Billion) |

|---|---|

| 2019 | 10.2 |

| 2020 | 10.9 |

| 2021 | 11.6 |

| 2022 | 12.4 |

| 2023 | 13.2 |

| 2024 | 14.5 |

Regional Analysis

The automotive PCB market is segmented into several key regions:

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

Asia-Pacific is expected to dominate the market during the forecast period, owing to the presence of major automotive manufacturers and PCB suppliers in countries like China, Japan, and South Korea. The region’s growth is also fueled by the increasing demand for electric vehicles and the rapid adoption of advanced electronics in vehicles.

Technological Advancements in Automotive PCBs

High-Density Interconnect (HDI) PCBs

HDI PCBs are becoming increasingly popular in the automotive industry due to their ability to accommodate more components in a smaller footprint. These PCBs feature finer traces, smaller vias, and higher layer counts, enabling the integration of complex electronic systems in vehicles.

Flexible and Rigid-Flex PCBs

Flexible and rigid-flex PCBs are gaining traction in the automotive industry, as they offer several advantages over traditional rigid PCBs. These PCBs can conform to the shape of the vehicle, reduce weight, and improve reliability by eliminating connectors and cables.

Thermal Management Solutions

As automotive electronic systems become more powerful and compact, thermal management becomes a critical concern. Advanced thermal management solutions, such as metal-core PCBs and embedded heat pipes, are being developed to dissipate heat efficiently and ensure the reliable operation of electronic components in harsh automotive environments.

Environmentally Friendly Materials

The automotive industry is increasingly focusing on sustainability and environmental responsibility. As a result, PCB Manufacturers are developing eco-friendly materials, such as halogen-free laminates and lead-free solders, to reduce the environmental impact of automotive electronics.

Challenges and Opportunities in the Automotive PCB Industry

Reliability and Durability

Automotive PCBs must withstand extreme temperatures, vibrations, and moisture, making reliability and durability critical concerns. Manufacturers are investing in advanced testing and qualification processes to ensure that their PCBs can meet the stringent requirements of the automotive industry.

Supply Chain Disruptions

The global supply chain has faced significant disruptions in recent years, including the COVID-19 pandemic and geopolitical tensions. These disruptions have highlighted the need for a more resilient and diversified supply chain in the automotive PCB industry.

Skill Shortage

As the automotive PCB industry becomes more complex and technology-driven, there is a growing shortage of skilled professionals. Companies are investing in training and development programs to bridge the skill gap and ensure a steady supply of qualified personnel.

Collaboration and Partnerships

Collaboration and partnerships between automotive OEMs, Tier 1 suppliers, and PCB manufacturers are becoming increasingly important to drive innovation and address industry challenges. Joint development projects, technology sharing, and strategic alliances are expected to become more common in the coming years.

Conclusion

The automotive PCB industry is undergoing a significant transformation, driven by the increasing demand for advanced electronic systems in vehicles. As the industry continues to evolve, manufacturers must focus on developing innovative solutions that meet the reliability, durability, and sustainability requirements of the automotive sector. By embracing technological advancements, addressing supply chain challenges, and fostering collaboration, the automotive PCB industry can unlock new opportunities and drive growth in the years ahead.

Frequently Asked Questions (FAQ)

1. What is the expected growth rate of the automotive PCB market?

The global automotive PCB market is expected to grow at a CAGR of 6.8% during the forecast period (2019-2024), reaching USD 14.5 billion by 2024.

2. Which region is expected to dominate the automotive PCB market?

Asia-Pacific is expected to dominate the automotive PCB market during the forecast period, owing to the presence of major automotive manufacturers and PCB suppliers in countries like China, Japan, and South Korea.

3. What are some of the technological advancements in automotive PCBs?

Some of the key technological advancements in automotive PCBs include high-density interconnect (HDI) PCBs, flexible and rigid-flex PCBs, thermal management solutions, and environmentally friendly materials.

4. What are the main challenges faced by the automotive PCB industry?

The main challenges faced by the automotive PCB industry include ensuring reliability and durability, managing supply chain disruptions, addressing the skill shortage, and fostering collaboration and partnerships.

5. How can automotive PCB manufacturers drive growth in the coming years?

Automotive PCB manufacturers can drive growth by embracing technological advancements, addressing supply chain challenges, investing in training and development programs, and fostering collaboration and partnerships with automotive OEMs and Tier 1 suppliers.

No responses yet