The Importance of PCB Cleanliness

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. They are responsible for connecting and supporting various components that make up a system. However, the performance of a PCB can be significantly affected by its cleanliness. Dirt, dust, and other contaminants can accumulate on the surface of a PCB, leading to a range of problems that can compromise the integrity and functionality of the entire system.

In this article, we will explore the various ways in which dirty PCBs can affect system performance, the importance of maintaining PCB cleanliness, and the best practices for ensuring that your PCBs remain clean and functional.

Why PCB Cleanliness Matters

PCB cleanliness is critical for several reasons. First and foremost, a clean PCB ensures that the electrical connections between components are secure and reliable. When contaminants build up on the surface of a PCB, they can interfere with these connections, leading to signal degradation, shorts, and other issues that can cause the system to malfunction.

Additionally, dirty PCBs can lead to overheating, as the contaminants can act as insulators and prevent proper heat dissipation. This can cause components to fail prematurely and can even pose a fire hazard in extreme cases.

Finally, PCB cleanliness is important for maintaining the overall reliability and longevity of a system. A clean PCB is less likely to experience problems over time, which can save businesses and individuals significant amounts of money in repair and replacement costs.

Common Contaminants and Their Effects

There are several common contaminants that can affect PCB performance. These include:

- Dust and Dirt: Dust and dirt can accumulate on the surface of a PCB over time, especially in environments with poor air filtration. These contaminants can interfere with electrical connections and cause signal degradation.

- Moisture: Moisture can be particularly damaging to PCBs, as it can lead to corrosion and short circuits. Humidity and condensation are common sources of moisture contamination.

- Oils and Grease: Oils and grease from human skin, machinery, and other sources can build up on the surface of a PCB, leading to poor electrical connections and signal degradation.

- Flux Residue: Flux is a substance used during the soldering process to prevent oxidation and improve solder joint quality. However, if flux residue is not properly cleaned off the PCB after soldering, it can cause corrosion and other issues.

- Solder Balls: Solder balls are small spheres of solder that can inadvertently adhere to the surface of a PCB during the manufacturing process. These balls can cause short circuits and other problems if not removed.

The effects of these contaminants can range from minor signal degradation to complete system failure. In some cases, the effects may not be immediately apparent, but can worsen over time as the contaminants continue to build up.

Best Practices for Maintaining PCB Cleanliness

Maintaining PCB cleanliness requires a proactive approach that involves regular cleaning and inspection. Here are some best practices for keeping your PCBs clean:

- Use Proper Handling Techniques: When handling PCBs, always use gloves or finger cots to avoid transferring oils and other contaminants from your skin onto the board. Additionally, avoid touching the surface of the PCB unnecessarily.

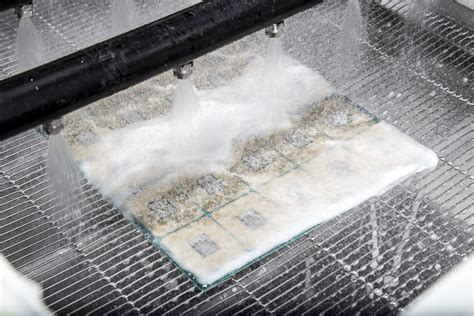

- Use Appropriate Cleaning Methods: There are several methods for cleaning PCBs, including manual cleaning with solvents or ultrasonic cleaning. The appropriate method will depend on the type of contaminant and the sensitivity of the components on the board.

- Perform Regular Inspections: Regular visual inspections of PCBs can help identify potential contamination issues before they become serious problems. Look for signs of corrosion, flux residue, solder balls, or other visible contaminants.

- Implement Proper Storage and Handling Procedures: When not in use, PCBs should be stored in a clean, dry environment with proper electrostatic discharge (ESD) protection. Additionally, proper handling procedures should be followed during assembly and installation to minimize the risk of contamination.

- Use Conformal Coatings: Conformal coatings are thin layers of insulating material that can be applied to the surface of a PCB to protect against moisture, dust, and other contaminants. While not a substitute for proper cleaning and handling, conformal coatings can provide an extra layer of protection in harsh environments.

| Contaminant | Effects | Cleaning Method |

|---|---|---|

| Dust and Dirt | Signal degradation, poor connections | Manual cleaning with solvents, compressed air |

| Moisture | Corrosion, short circuits | Baking, desiccant drying |

| Oils and Grease | Poor connections, signal degradation | Manual cleaning with solvents, ultrasonic cleaning |

| Flux Residue | Corrosion, poor connections | Manual cleaning with solvents, saponifier solution |

| Solder Balls | Short circuits, poor connections | Manual removal with tweezers, solder wick |

The Role of Cleanliness Testing

In addition to regular cleaning and inspection, cleanliness testing can be a valuable tool for ensuring the reliability and performance of PCBs. Cleanliness testing involves the use of specialized equipment and techniques to measure the level of contamination on a PCB’s surface.

There are several methods for performing cleanliness testing, including:

- Ionic Contamination Testing: This method uses a specialized solution to measure the concentration of ionic contaminants on the surface of a PCB. The solution is applied to the board and then analyzed using a conductivity meter.

- Resistivity of Solvent Extract (ROSE) Testing: This method involves immersing a PCB in a solvent and then measuring the resistivity of the resulting solution. The lower the resistivity, the higher the level of contamination.

- Surface Insulation Resistance (SIR) Testing: This method measures the electrical resistance between conductors on a PCB’s surface. A decrease in resistance over time can indicate the presence of contaminants that are causing leakage currents.

Cleanliness testing can be performed at various stages of the PCB manufacturing process, including after initial cleaning, after conformal coating application, and before final assembly. By identifying contamination issues early on, manufacturers can take corrective action to ensure that the final product meets cleanliness standards.

Industry Standards for PCB Cleanliness

To ensure consistency and reliability in PCB manufacturing, several industry standards have been developed that specify acceptable levels of cleanliness for various applications. These standards are typically based on the intended use of the PCB and the environmental conditions in which it will be operating.

Some of the most commonly used industry standards for PCB cleanliness include:

- IPC-5704: This standard specifies cleanliness requirements for printed board assemblies used in high-performance electronic products. It includes requirements for ionic contamination, surface organic contamination, and particulate contamination.

- IPC-6012: This standard specifies general performance requirements for rigid printed boards, including requirements for cleanliness and surface finish.

- J-STD-001: This standard specifies requirements for soldered electrical and electronic assemblies, including requirements for cleanliness and solderability.

Manufacturers who adhere to these standards can provide assurance to their customers that their PCBs meet industry-accepted levels of cleanliness and reliability.

Conclusion

PCB cleanliness is a critical factor in ensuring the reliability and performance of electronic systems. Contamination from dust, moisture, oils, flux residue, and solder balls can lead to signal degradation, short circuits, and other issues that can cause system failure.

To maintain PCB cleanliness, manufacturers and assemblers must implement proper handling and cleaning procedures, perform regular inspections and testing, and adhere to industry standards for cleanliness levels.

By prioritizing PCB cleanliness throughout the manufacturing process and product lifecycle, businesses can ensure that their electronic products meet the highest standards of quality and reliability.

Frequently Asked Questions

1. What are the most common sources of PCB contamination?

The most common sources of PCB contamination include dust and dirt from the environment, moisture from humidity and condensation, oils and grease from human skin and machinery, flux residue from the soldering process, and solder balls that can adhere to the board during manufacturing.

2. How can I tell if my PCB is contaminated?

Visual inspection is the first step in identifying PCB contamination. Look for signs of corrosion, flux residue, solder balls, or other visible contaminants on the surface of the board. Cleanliness testing methods such as ionic contamination testing, ROSE testing, and SIR testing can also be used to measure the level of contamination on a PCB’s surface.

3. What are the best methods for cleaning PCBs?

The best method for cleaning a PCB will depend on the type of contaminant and the sensitivity of the components on the board. Manual cleaning with solvents can be effective for removing oils, grease, and flux residue, while ultrasonic cleaning can be used for more stubborn contaminants. Compressed air can be used to remove dust and dirt, while baking or desiccant drying can be used to remove moisture.

4. How often should PCBs be cleaned and inspected?

The frequency of cleaning and inspection will depend on the environment in which the PCB is being used and the level of contamination it is exposed to. In general, PCBs should be inspected and cleaned on a regular basis, especially if they are being used in harsh or dirty environments. Manufacturers may specify recommended cleaning and inspection intervals based on the intended use of the product.

5. What are the consequences of not maintaining PCB cleanliness?

Failing to maintain PCB cleanliness can lead to a range of problems, including signal degradation, short circuits, corrosion, and premature component failure. In extreme cases, contamination can even pose a fire hazard. These issues can result in system malfunctions, reduced reliability, and increased repair and replacement costs over time. Maintaining PCB cleanliness is therefore critical for ensuring the long-term performance and reliability of electronic products.

No responses yet