Introduction to PCB Layout Design

Printed Circuit Board (PCB) layout design is a crucial step in the development of electronic devices. It involves the arrangement of components and the routing of electrical connections on a circuit board to ensure optimal performance, reliability, and manufacturability. A well-designed PCB layout can significantly enhance the functionality and longevity of an electronic product, while a poorly designed layout can lead to various issues such as signal integrity problems, electromagnetic interference (EMI), and manufacturing difficulties.

In this article, we will delve into the intricacies of PCB layout design services, exploring the key considerations, best practices, and tools involved in creating high-quality PCB layouts. Whether you are an electronics engineer, a hardware designer, or a product development manager, understanding the fundamentals of PCB layout design is essential for successful electronic product development.

The Importance of PCB Layout Design

Ensuring Proper Functionality

A well-designed PCB layout is crucial for ensuring the proper functionality of an electronic device. The placement of components and the routing of traces directly impact the electrical performance of the circuit. Poor layout decisions can lead to issues such as signal integrity problems, crosstalk, and power supply noise, which can compromise the overall functionality of the device.

Optimizing Signal Integrity

Signal integrity is a critical aspect of PCB layout design. It refers to the ability of a signal to propagate through the circuit without undue distortion or attenuation. Factors such as trace width, spacing, and length can significantly affect signal integrity. A good PCB layout design takes into account the characteristics of the signals being transmitted and applies appropriate design techniques to minimize signal degradation and ensure reliable communication between components.

Minimizing Electromagnetic Interference (EMI)

Electromagnetic Interference (EMI) is a common concern in electronic devices. It occurs when the electromagnetic fields generated by one component interfere with the operation of another component or nearby devices. PCB layout design plays a vital role in minimizing EMI by implementing proper grounding, shielding, and trace routing techniques. By carefully considering the placement of components and the routing of traces, designers can reduce the coupling of electromagnetic fields and mitigate the risk of EMI-related issues.

Facilitating Manufacturability

PCB layout design also has a significant impact on the manufacturability of the circuit board. A well-designed layout takes into account the manufacturing processes and constraints, such as minimum trace widths, spacing requirements, and component placement tolerances. By adhering to industry standards and considering manufacturing capabilities, designers can ensure that the PCB can be efficiently and reliably manufactured, reducing the likelihood of production delays or quality issues.

Key Considerations in PCB Layout Design

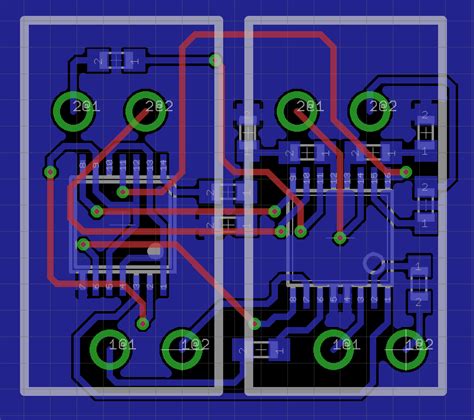

Component Placement

Component placement is a critical aspect of PCB layout design. The positioning of components on the board can affect signal integrity, thermal management, and overall board size. When placing components, designers should consider factors such as signal flow, power distribution, and mechanical constraints. It is important to group related components together, minimize the distance between connected components, and ensure proper spacing for heat dissipation and manufacturability.

Routing and Trace Design

Routing and trace design involve the creation of conductive paths that connect the components on the PCB. The width, spacing, and length of traces can significantly impact signal integrity and EMI performance. Designers should follow best practices such as using appropriate trace widths based on current requirements, maintaining consistent impedance, and avoiding sharp bends or unnecessary crossovers. Additionally, proper grounding and power distribution techniques should be employed to ensure stable and noise-free operation.

Layer Stackup Design

PCB layer stackup refers to the arrangement of conductive and insulating layers in a multi-layer PCB. The layer stackup design plays a crucial role in signal integrity, power distribution, and EMI performance. Designers should carefully consider the number of layers, the thickness of each layer, and the arrangement of power and ground planes. A well-designed layer stackup can provide effective shielding, minimize crosstalk, and ensure proper impedance control throughout the board.

Thermal Management

Thermal management is an important consideration in PCB layout design, especially for high-power devices or applications with significant heat dissipation requirements. Proper thermal management helps prevent component overheating, which can lead to performance degradation or even device failure. Designers should incorporate features such as thermal vias, heat sinks, and adequate copper pour to facilitate heat dissipation. The placement of heat-generating components should also be carefully considered to ensure effective heat distribution and avoid localized hot spots.

Design for Manufacturing (DFM)

Design for Manufacturing (DFM) is an approach that focuses on designing PCBs with manufacturing considerations in mind. It involves adhering to industry standards, manufacturing tolerances, and process capabilities to ensure the PCB can be efficiently and reliably produced. DFM considerations include minimum trace widths and spacing, component placement tolerances, soldermask and silkscreen requirements, and testability features. By incorporating DFM principles into the PCB layout design process, designers can reduce manufacturing costs, improve yield, and minimize the risk of production issues.

PCB Layout Design Tools and Software

To facilitate the PCB layout design process, various tools and software solutions are available in the market. These tools provide a range of features and capabilities to help designers create accurate and efficient PCB layouts. Some popular PCB layout design tools include:

Altium Designer

Altium Designer is a comprehensive PCB design software that offers a wide range of features for schematic capture, PCB layout, and design rule checking. It provides a user-friendly interface, advanced routing capabilities, and 3D visualization tools to help designers create high-quality PCB layouts.

Cadence Allegro PCB Designer

Cadence Allegro PCB Designer is a powerful PCB layout design solution that offers advanced routing, placement, and analysis capabilities. It supports complex design requirements, including high-speed digital designs and RF/microwave applications. Allegro PCB Designer provides a robust set of tools for constraint management, signal integrity analysis, and manufacturability checks.

Mentor Graphics PADS

Mentor Graphics PADS is a PCB design software suite that includes schematic capture, PCB layout, and analysis tools. It offers a streamlined design flow, intuitive user interface, and advanced features for high-speed design and manufacturing optimization. PADS also provides integration with mechanical CAD tools for effective collaboration between electrical and mechanical design teams.

KiCad EDA

KiCad EDA is an open-source PCB design software that provides a complete suite of tools for schematic capture, PCB layout, and design rule checking. It offers a user-friendly interface, extensive component libraries, and support for various file formats. KiCad is a popular choice for hobbyists, students, and small-scale projects due to its free availability and active community support.

Best Practices for PCB Layout Design

To ensure optimal performance and manufacturability of PCBs, designers should follow certain best practices throughout the layout design process. Some key best practices include:

Keeping Signal Traces Short and Direct

Minimizing the length of signal traces is crucial for maintaining signal integrity and reducing the risk of signal degradation. Designers should aim to keep signal traces as short and direct as possible, avoiding unnecessary bends or detours. This helps minimize the impact of parasitic inductance and capacitance, which can cause signal distortion and reflections.

Proper Grounding and Power Distribution

Effective grounding and power distribution are essential for stable and noise-free operation of the PCB. Designers should implement a solid ground plane to provide a low-impedance return path for signals and minimize ground loops. Power planes should be strategically placed to ensure uniform power distribution and minimize voltage drops. Proper decoupling capacitors should be used near power pins of components to suppress high-frequency noise and provide local energy storage.

Avoiding Crosstalk and Signal Interference

Crosstalk and signal interference can occur when adjacent traces or components are too close to each other, causing unwanted coupling of signals. To mitigate crosstalk, designers should maintain adequate spacing between traces, especially for high-speed or sensitive signals. Using ground traces or guard traces between critical signal traces can also help reduce crosstalk. Additionally, proper layer stackup design and the use of shielding techniques can minimize signal interference.

Adhering to Design Rules and Constraints

PCB layout design software typically provides a set of design rules and constraints that help ensure the manufacturability and reliability of the PCB. These rules include minimum trace widths, spacing requirements, drill sizes, and annular ring specifications. Designers should familiarize themselves with the relevant design rules and ensure that the layout adheres to these constraints. Regularly running design rule checks (DRC) during the layout process can help identify and resolve any violations.

Collaborating with Manufacturing Partners

Effective collaboration with manufacturing partners is essential for successful PCB layout design. Designers should engage with the manufacturing team early in the design process to discuss manufacturing capabilities, constraints, and best practices. This collaboration helps ensure that the PCB design is optimized for the specific manufacturing processes and can be efficiently produced. Regular communication and design reviews with the manufacturing team can help identify potential issues and make necessary adjustments before finalizing the layout.

Common PCB Layout Design Challenges and Solutions

PCB layout design can present various challenges that designers must navigate to achieve a successful outcome. Some common challenges and their solutions include:

High-Speed Design Considerations

Designing PCBs for high-speed applications requires special considerations to ensure signal integrity and minimize EMI. Challenges such as impedance matching, trace routing, and termination techniques must be addressed. Solutions include using controlled impedance traces, implementing proper termination strategies, and employing simulation tools to analyze and optimize high-speed signals.

Dealing with Limited Board Space

As electronic devices become more compact and feature-rich, designers often face the challenge of accommodating all the necessary components within a limited board space. Solutions include using smaller component packages, implementing multi-layer PCBs, and employing advanced routing techniques such as via-in-pad or blind and buried vias. Careful component placement and creative layout strategies can also help maximize board space utilization.

Managing Thermal Constraints

Thermal management can be a significant challenge in PCB layout design, especially for high-power devices or densely populated boards. Overheating can lead to performance degradation and reliability issues. Solutions include using thermal vias to conduct heat away from components, incorporating heat sinks or thermal pads, and strategically placing components to promote effective heat dissipation. Thermal simulation tools can also help analyze and optimize the thermal performance of the PCB.

Ensuring Manufacturability and Testability

Designing PCBs that are manufacturable and testable is crucial for successful production and quality assurance. Challenges include adhering to manufacturing tolerances, incorporating testability features, and minimizing the risk of defects. Solutions involve following DFM guidelines, implementing test points or boundary scan techniques, and collaborating closely with the manufacturing team to ensure the design aligns with their capabilities and processes.

Frequently Asked Questions (FAQ)

1. What is the difference between PCB layout and PCB design?

PCB layout and PCB design are closely related but distinct aspects of the overall PCB development process. PCB design encompasses the entire process of creating a PCB, including schematic capture, component selection, and layout. PCB layout, on the other hand, specifically refers to the process of arranging components and routing traces on the PCB. It is a critical step within the overall PCB design process.

2. How do I choose the right PCB layout design software?

Choosing the right PCB layout design software depends on several factors, including your specific design requirements, budget, and level of expertise. Consider factors such as the complexity of your designs, the features and capabilities offered by the software, ease of use, and compatibility with your existing design tools and workflows. It’s also helpful to evaluate the level of support, documentation, and community resources available for the software.

3. What are the benefits of outsourcing PCB layout design services?

Outsourcing PCB layout design services can offer several benefits, including access to specialized expertise, faster turnaround times, and cost savings. PCB layout design service providers have experienced designers who are well-versed in industry standards and best practices. They can handle complex designs efficiently and ensure adherence to manufacturing guidelines. Outsourcing also allows you to focus on core competencies while leveraging external resources for PCB layout tasks.

4. How can I ensure the manufacturability of my PCB layout?

To ensure the manufacturability of your PCB layout, it is important to follow design for manufacturing (DFM) guidelines and collaborate closely with your manufacturing partner. Adhere to the manufacturer’s specifications for minimum trace widths, spacing, drill sizes, and other design rules. Incorporate testability features and consider the manufacturing processes and constraints during the layout design phase. Regular communication and design reviews with the manufacturing team can help identify and resolve any potential manufacturability issues.

5. What are some common pitfalls to avoid in PCB layout design?

Some common pitfalls to avoid in PCB layout design include:

- Neglecting signal integrity considerations, such as proper trace routing and termination.

- Overlooking thermal management requirements, leading to overheating and reliability issues.

- Failing to adhere to design rules and manufacturing constraints, resulting in manufacturability problems.

- Not considering the impact of component placement on signal performance and EMI.

- Inadequate documentation and communication with the manufacturing team, leading to production delays or quality issues.

By being aware of these pitfalls and taking proactive steps to address them, designers can minimize the risk of design errors and ensure a successful PCB layout.

Conclusion

PCB layout design is a critical aspect of electronic product development, directly impacting the functionality, reliability, and manufacturability of the final product. A well-designed PCB layout ensures optimal signal integrity, minimizes EMI, and facilitates efficient manufacturing processes. By understanding the key considerations, best practices, and tools involved in PCB layout design, designers can create high-quality layouts that meet the specific requirements of their applications.

Effective PCB layout design requires a combination of technical expertise, attention to detail, and collaboration with manufacturing partners. Designers must navigate various challenges, such as high-speed design considerations, limited board space, thermal constraints, and manufacturability requirements. By leveraging the right tools, following best practices, and engaging in open communication with stakeholders, designers can overcome these challenges and deliver successful PCB layouts.

As technology continues to advance and electronic devices become more complex, the importance of PCB layout design services will only continue to grow. Whether you are an in-house design team or considering outsourcing PCB layout tasks, investing in high-quality PCB layout design is crucial for the success of your electronic products. By prioritizing PCB layout design and adopting a comprehensive approach, you can unlock the full potential of your electronic designs and stay ahead in the competitive landscape of electronic product development.

No responses yet