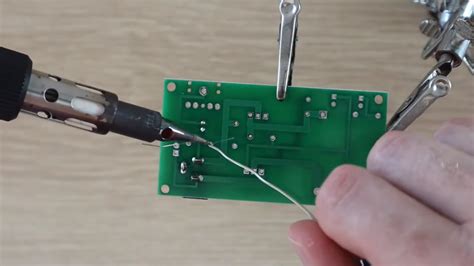

1. Solder Bridging

Solder bridging occurs when excess solder creates an unintended connection between two or more adjacent pads or traces on the PCB. This can lead to short circuits and cause the device to malfunction.

Causes of Solder Bridging

- Excessive solder use

- Improper solder paste application

- Incorrect component placement

- Inadequate cleaning of the PCB before soldering

Prevention and Correction

- Use the appropriate amount of solder

- Ensure proper solder paste application using stencils or dispensers

- Double-check component placement before soldering

- Clean the PCB thoroughly before soldering

- Use a soldering iron with a fine tip to remove excess solder

2. Cold Solder Joints

Cold solder joints occur when the solder fails to melt completely, resulting in a weak and unreliable connection. This can happen due to insufficient heat or improper soldering technique.

Causes of Cold Solder Joints

- Insufficient soldering iron temperature

- Inadequate preheating of the PCB and components

- Improper soldering technique

- Contaminated or oxidized solder pads or component leads

Prevention and Correction

- Ensure the soldering iron is set to the appropriate temperature

- Preheat the PCB and components before soldering

- Use the correct soldering technique, applying heat to both the pad and the component lead

- Clean and deoxidize the solder pads and component leads before soldering

- Reheat and add more solder to the joint to correct a cold solder joint

3. Insufficient Solder

Insufficient solder can lead to weak and unreliable connections, which may fail over time due to mechanical stress or vibration.

Causes of Insufficient Solder

- Inadequate solder paste application

- Improper soldering technique

- Incorrect solder wire diameter

Prevention and Correction

- Apply the appropriate amount of solder paste using stencils or dispensers

- Use the correct soldering technique, applying enough solder to create a proper joint

- Choose the appropriate solder wire diameter for the job

- Add more solder to the joint to correct insufficient solder

4. Tombstoning

Tombstoning, also known as drawbridging, occurs when a surface-mount component stands up on one end during the soldering process. This can happen due to uneven heating or an imbalance in the solder paste on the pads.

Causes of Tombstoning

- Uneven heating of the component during soldering

- Imbalanced solder paste application on the pads

- Incorrect component placement

- Mismatch in the thermal mass of the component and the PCB

Prevention and Correction

- Ensure even heating of the component during soldering

- Apply solder paste evenly on both pads

- Double-check component placement before soldering

- Choose components with a thermal mass that matches the PCB

- Reflow the solder joint and reposition the component to correct tombstoning

5. Solder Balls

Solder balls are small spheres of solder that form on the PCB during the soldering process. They can cause short circuits and other issues if not removed.

Causes of Solder Balls

- Excessive solder paste application

- Improper solder paste mixing

- Contamination of the solder paste or PCB

- Incorrect reflow oven temperature profile

Prevention and Correction

- Apply the appropriate amount of solder paste using stencils or dispensers

- Mix the solder paste thoroughly before use

- Keep the solder paste and PCB clean and free from contaminants

- Optimize the reflow oven temperature profile

- Remove solder balls using a soldering iron or specialized tools

6. Flux Residue

Flux is a chemical agent used to clean and prepare the surfaces of the PCB and components for soldering. However, if not properly cleaned after soldering, flux residue can lead to corrosion and other issues.

Causes of Flux Residue

- Inadequate cleaning after soldering

- Use of inappropriate flux

- Excessive flux application

Prevention and Correction

- Clean the PCB thoroughly after soldering using isopropyl alcohol or a specialized cleaning solution

- Choose the appropriate flux for the job

- Apply flux sparingly, only where needed

- Use a no-clean flux to minimize residue

7. Lifted Pads

Lifted pads occur when the copper pad on the PCB separates from the board during the soldering process. This can happen due to excessive heat or mechanical stress.

Causes of Lifted Pads

- Excessive soldering iron temperature

- Prolonged heat application

- Improper handling or excessive mechanical stress

- Poor PCB design or manufacturing

Prevention and Correction

- Use the appropriate soldering iron temperature

- Apply heat for the minimum time necessary to create a proper joint

- Handle the PCB and components with care

- Ensure the PCB is designed and manufactured to withstand the soldering process

- Repair lifted pads using specialized techniques, such as micro-soldering or jumper wires

8. Thermal Damage

Thermal damage can occur when the PCB or components are exposed to excessive heat during the soldering process. This can lead to delamination, warping, or other structural issues.

Causes of Thermal Damage

- Excessive soldering iron temperature

- Prolonged heat application

- Incorrect reflow oven temperature profile

- Inadequate cooling after soldering

Prevention and Correction

- Use the appropriate soldering iron temperature

- Apply heat for the minimum time necessary to create a proper joint

- Optimize the reflow oven temperature profile

- Allow the PCB and components to cool gradually after soldering

- Replace damaged components or PCBs

9. Electrostatic Discharge (ESD) Damage

Electrostatic discharge (ESD) can damage sensitive electronic components during the soldering process. This can lead to latent defects that may cause the device to fail prematurely.

Causes of ESD Damage

- Inadequate ESD protection during handling and soldering

- Use of non-ESD-safe tools and materials

- Improper grounding of personnel and equipment

Prevention and Correction

- Implement proper ESD protection measures, such as grounded workstations and personnel grounding straps

- Use ESD-safe tools and materials, such as antistatic mats and packaging

- Train personnel on ESD safety procedures

- Replace ESD-damaged components

10. Incorrect Component Orientation

Incorrect component orientation can lead to device malfunction or failure. This can happen due to human error or improper machine placement.

Causes of Incorrect Component Orientation

- Human error during manual placement

- Improper machine programming or calibration

- Inadequate visual inspection

Prevention and Correction

- Double-check component orientation before soldering

- Ensure proper machine programming and calibration

- Implement thorough visual inspection procedures

- Correct component orientation using a soldering iron and tweezers

Frequently Asked Questions (FAQ)

1. What is the most common issue in PCB Soldering?

One of the most common issues in PCB soldering is solder bridging. This occurs when excess solder creates an unintended connection between two or more adjacent pads or traces on the PCB, leading to short circuits and device malfunction.

2. How can I prevent cold solder joints?

To prevent cold solder joints, ensure that your soldering iron is set to the appropriate temperature, preheat the PCB and components before soldering, use the correct soldering technique, and clean and deoxidize the solder pads and component leads before soldering.

3. What causes tombstoning in surface-mount components?

Tombstoning can be caused by uneven heating of the component during soldering, imbalanced solder paste application on the pads, incorrect component placement, or a mismatch in the thermal mass of the component and the PCB.

4. How do I remove flux residue after soldering?

To remove flux residue, clean the PCB thoroughly after soldering using isopropyl alcohol or a specialized cleaning solution. You can also use a no-clean flux to minimize residue.

5. What ESD protection measures should I implement during PCB soldering?

To protect against ESD damage, implement proper ESD protection measures, such as grounded workstations and personnel grounding straps, use ESD-safe tools and materials, and train personnel on ESD safety procedures.

| Issue | Causes | Prevention and Correction |

|---|---|---|

| Solder Bridging | – Excessive solder use – Improper solder paste application |

– Use the appropriate amount of solder – Ensure proper solder paste application |

| Cold Solder Joints | – Insufficient soldering iron temperature – Inadequate preheating of the PCB and components |

– Ensure the soldering iron is set to the appropriate temperature – Preheat the PCB and components before soldering |

| Insufficient Solder | – Inadequate solder paste application – Improper soldering technique |

– Apply the appropriate amount of solder paste using stencils or dispensers – Use the correct soldering technique |

| Tombstoning | – Uneven heating of the component during soldering – Imbalanced solder paste application on the pads |

– Ensure even heating of the component during soldering – Apply solder paste evenly on both pads |

| Solder Balls | – Excessive solder paste application – Improper solder paste mixing |

– Apply the appropriate amount of solder paste using stencils or dispensers – Mix the solder paste thoroughly before use |

| Flux Residue | – Inadequate cleaning after soldering – Use of inappropriate flux |

– Clean the PCB thoroughly after soldering using isopropyl alcohol or a specialized cleaning solution – Choose the appropriate flux for the job |

| Lifted Pads | – Excessive soldering iron temperature – Prolonged heat application |

– Use the appropriate soldering iron temperature – Apply heat for the minimum time necessary to create a proper joint |

| Thermal Damage | – Excessive soldering iron temperature – Prolonged heat application |

– Use the appropriate soldering iron temperature – Apply heat for the minimum time necessary to create a proper joint |

| Electrostatic Discharge Damage | – Inadequate ESD protection during handling and soldering – Use of non-ESD-safe tools and materials |

– Implement proper ESD protection measures, such as grounded workstations and personnel grounding straps – Use ESD-safe tools and materials |

| Incorrect Component Orientation | – Human error during manual placement – Improper machine programming or calibration |

– Double-check component orientation before soldering – Ensure proper machine programming and calibration |

In conclusion, PCB soldering is a complex process that requires attention to detail and adherence to best practices to ensure the reliability, functionality, and longevity of electronic devices. By understanding and addressing the ten critical issues discussed in this article, manufacturers can improve the quality of their soldered PCBs and reduce the risk of defects and malfunctions. Implementing proper soldering techniques, using appropriate tools and materials, and providing adequate training to personnel are essential steps in achieving successful PCB soldering outcomes.

No responses yet