What is Electronic Contract Manufacturing?

Electronic Contract Manufacturing, also known as Electronics Manufacturing Services (EMS), is a service provided by companies that specialize in manufacturing electronic components and products for other companies. The contract manufacturer is responsible for procuring raw materials, assembling the products, testing them for quality, and packaging them for shipment.

Types of Electronic Contract Manufacturing

There are several types of Electronic Contract Manufacturing, each with its own set of advantages and disadvantages. Let’s take a closer look at the most common types:

1. Printed Circuit Board (PCB) Assembly

PCB Assembly is the process of soldering electronic components onto a printed circuit board. This is one of the most common services offered by contract manufacturers. PCB assembly can be done manually or using automated equipment, depending on the complexity of the board and the volume of production required.

2. Cable and Harness Assembly

Cable and harness assembly involves the production of custom cables and Wire Harnesses for electronic products. This includes cutting wires to specific lengths, stripping the insulation, crimping terminals, and bundling the wires together. Cable and harness assembly requires skilled labor and specialized equipment to ensure the quality and reliability of the final product.

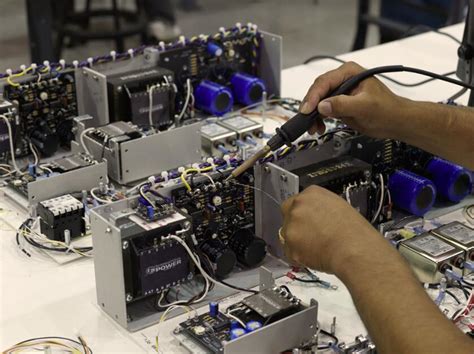

3. Box Build Assembly

Box build assembly is the process of assembling a complete electronic product, including the enclosure, PCBs, cables, and any other components required. This type of manufacturing requires a high level of coordination between the contract manufacturer and the client to ensure that all components are available and that the final product meets the required specifications.

4. Electronic Testing and Inspection

Electronic testing and inspection are critical steps in the manufacturing process to ensure that the products meet the required quality standards. This includes functional testing, in-circuit testing, and automated optical inspection (AOI). Contract manufacturers often have specialized equipment and trained personnel to perform these tests efficiently and accurately.

Advantages of Electronic Contract Manufacturing

Outsourcing Electronic Manufacturing to a contract manufacturer offers several advantages for companies, including:

-

Cost Savings: Contract manufacturers can often produce products at a lower cost than in-house manufacturing due to economies of scale, lower labor costs, and access to specialized equipment.

-

Flexibility: Contract manufacturers can quickly adapt to changes in demand, allowing companies to scale up or down production as needed without investing in additional equipment or personnel.

-

Expertise: Contract manufacturers have specialized knowledge and experience in electronic manufacturing, which can lead to improved product quality and reliability.

-

Focus on Core Competencies: By outsourcing manufacturing, companies can focus on their core competencies, such as product design, marketing, and sales, while leaving the manufacturing to the experts.

Challenges of Electronic Contract Manufacturing

While Electronic Contract Manufacturing offers many benefits, there are also some challenges that companies should be aware of, including:

-

Communication: Effective communication between the client and the contract manufacturer is essential to ensure that the products are manufactured to the required specifications and quality standards.

-

Intellectual Property Protection: Companies need to ensure that their intellectual property is protected when outsourcing manufacturing to a third-party company.

-

Quality Control: While contract manufacturers are responsible for ensuring product quality, companies still need to have their own quality control measures in place to verify that the products meet their standards.

-

Supply Chain Management: Companies need to manage their supply chain effectively to ensure that the contract manufacturer has access to the required components and materials in a timely manner.

Choosing an Electronic Contract Manufacturer

Choosing the right Electronic Contract Manufacturer is critical to the success of your project. Here are some factors to consider when selecting a contract manufacturer:

1. Experience and Expertise

Look for a contract manufacturer with experience and expertise in the type of product you are manufacturing. They should have a proven track record of producing high-quality products and be able to provide references from satisfied clients.

2. Quality Management System

The contract manufacturer should have a robust quality management system in place to ensure that the products meet the required quality standards. Look for certifications such as ISO 9001, which demonstrates that the company has a documented quality management system.

3. Technical Capabilities

The contract manufacturer should have the technical capabilities to manufacture your product, including the necessary equipment, software, and skilled personnel. They should also be able to provide value-added services such as design for manufacturing (DFM) and testing.

4. Cost and Delivery

Cost and delivery are important factors to consider when selecting a contract manufacturer. Look for a company that offers competitive pricing and can meet your delivery requirements. However, be wary of companies that offer prices that seem too good to be true, as this may indicate poor quality or hidden costs.

5. Location

The location of the contract manufacturer can also be an important consideration, particularly if you need to visit the facility regularly or if you have specific shipping requirements. Consider factors such as time zone differences, language barriers, and cultural differences when selecting a contract manufacturer in a different country.

Best Practices for Working with an Electronic Contract Manufacturer

Once you have selected an Electronic Contract Manufacturer, there are several best practices that you can follow to ensure a successful Partnership:

1. Clearly Define Requirements

Clearly define your product requirements, including specifications, quality standards, and delivery dates. Provide the contract manufacturer with detailed documentation, such as drawings, bills of materials (BOM), and test procedures.

2. Communicate Regularly

Maintain regular communication with the contract manufacturer throughout the project. Schedule regular status meetings and provide feedback on any issues or concerns in a timely manner.

3. Monitor Quality

Implement a quality control plan to monitor the quality of the products being manufactured. This may include regular inspections, testing, and audits of the contract manufacturer’s facility.

4. Manage Inventory

Work with the contract manufacturer to manage inventory levels and ensure that components and materials are available when needed. Consider implementing a just-in-time (JIT) inventory system to minimize inventory costs.

5. Plan for the Future

Plan for the future by considering the scalability of the contract manufacturer and their ability to support your growth. Consider establishing a long-term partnership that can evolve as your business grows and changes.

Frequently Asked Questions (FAQ)

1. What is the difference between Electronic Contract Manufacturing and Original Equipment Manufacturing (OEM)?

Electronic Contract Manufacturing involves outsourcing the manufacturing of electronic products to a third-party company, while Original Equipment Manufacturing involves a company designing and manufacturing products that are then sold under another company’s brand name.

2. How do I know if Electronic Contract Manufacturing is right for my company?

Electronic Contract Manufacturing may be right for your company if you lack the in-house expertise, equipment, or capacity to manufacture your products efficiently and cost-effectively. It can also be a good option if you want to focus on your core competencies, such as product design and marketing, while leaving the manufacturing to the experts.

3. What are the risks of outsourcing manufacturing to a contract manufacturer?

The risks of outsourcing manufacturing to a contract manufacturer include potential quality issues, intellectual property theft, supply chain disruptions, and communication challenges. It is important to carefully vet potential contract manufacturers and establish clear communication channels and quality control measures to mitigate these risks.

4. How much does Electronic Contract Manufacturing cost?

The cost of Electronic Contract Manufacturing varies depending on factors such as the complexity of the product, the volume of production, and the location of the contract manufacturer. In general, contract manufacturing can be more cost-effective than in-house manufacturing due to economies of scale and lower labor costs.

5. How long does it take to set up a contract manufacturing partnership?

The time required to set up a contract manufacturing partnership varies depending on the complexity of the product and the specific requirements of the client. In general, it can take several months to select a contract manufacturer, negotiate terms, and set up the necessary processes and systems. However, once the partnership is established, production can typically begin relatively quickly.

Conclusion

Electronic Contract Manufacturing is a valuable service for companies looking to outsource the manufacturing of their electronic products. By partnering with a contract manufacturer, companies can reduce costs, improve flexibility, and focus on their core competencies. However, it is important to carefully select a contract manufacturer and establish clear communication channels and quality control measures to ensure a successful partnership. By following best practices and planning for the future, companies can leverage the benefits of Electronic Contract Manufacturing to grow their business and stay competitive in today’s fast-paced electronic industry.

| Advantages of Electronic Contract Manufacturing | Challenges of Electronic Contract Manufacturing |

|---|---|

| Cost Savings | Communication |

| Flexibility | Intellectual Property Protection |

| Expertise | Quality Control |

| Focus on Core Competencies | Supply Chain Management |

No responses yet