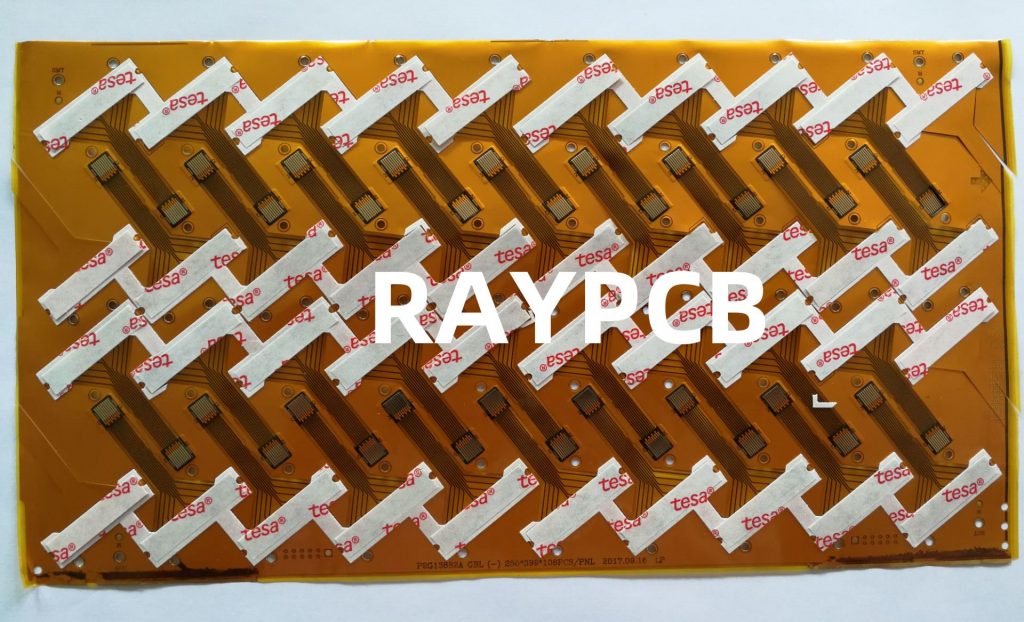

What is PCB-assembly-service.com/?p=2072″>Copper Foil?

Copper foil is a thin sheet of copper, typically ranging from 9 to 175 microns (0.0004 to 0.007 inches) in thickness. It serves as the conductive layer in printed Circuit Boards, including Flexible PCBs. The copper foil is laminated onto a flexible substrate, such as polyimide or polyester, and then etched to create the desired circuit pattern.

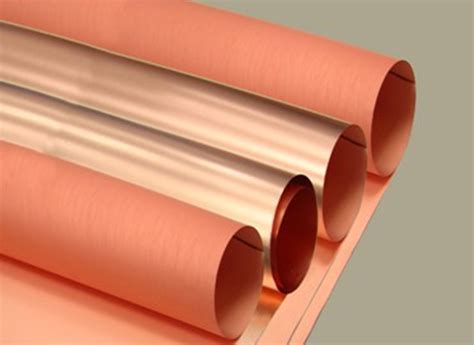

Copper foil is available in two main types:

- Rolled Annealed (RA) Copper

- Electrodeposited (ED) Copper

Each type has its own unique properties and manufacturing process, which we’ll discuss in more detail below.

Rolled Annealed (RA) Copper

Manufacturing Process

RA copper foil is manufactured using a mechanical process. High-purity copper is first melted and cast into a thick slab. The slab is then repeatedly rolled between large rollers to reduce its thickness gradually. As the copper is rolled, it undergoes work hardening, which increases its strength and hardness.

To restore the copper’s ductility and electrical conductivity, the foil undergoes an annealing process. During annealing, the copper is heated to a specific temperature and then cooled slowly. This heat treatment relaxes the internal stresses in the metal, making it more malleable and improving its electrical properties.

Properties of RA Copper

RA copper foil has several distinct properties that make it suitable for certain flex circuit applications:

- Higher ductility: Thanks to the annealing process, RA copper is more ductile than ED copper. This means it can withstand more bending and flexing without cracking or breaking.

- Better thermal conductivity: RA copper has a higher thermal conductivity than ED copper, which allows it to dissipate heat more effectively. This property is essential for applications where heat management is critical.

- Higher electrical conductivity: RA copper typically has a higher electrical conductivity than ED copper, which means it can carry electrical signals with less resistance.

- Smoother surface: The rolling process used to manufacture RA copper results in a smoother surface finish compared to ED copper. This smoother surface can be advantageous for certain applications, such as high-frequency circuits.

Applications of RA Copper

RA copper foil is commonly used in flex circuit applications that require:

- High flexibility and durability

- Excellent heat dissipation

- High electrical conductivity

- Smooth surface finish

Some examples of applications where RA copper is preferred include:

- Wearable electronics

- Medical devices

- Aerospace and defense systems

- High-frequency circuits

Electrodeposited (ED) Copper

Manufacturing Process

ED copper foil is produced using an electrochemical process. A thin layer of copper is deposited onto a rotating stainless steel drum immersed in an electrolytic solution containing copper ions. An electric current is applied, causing the copper ions to migrate to the drum’s surface and form a thin, uniform layer of copper foil.

The thickness of the ED copper foil can be precisely controlled by adjusting the current density and the deposition time. Once the desired thickness is achieved, the copper foil is peeled off the drum and wound into rolls.

Properties of ED Copper

ED copper foil has its own set of unique properties that make it suitable for certain flex circuit applications:

- Higher tensile strength: ED copper has a higher tensile strength than RA copper, which means it can withstand more stress before breaking. This property is particularly important for applications where the flex circuit may be subjected to high levels of stress or strain.

- Better dimensional stability: ED copper has better dimensional stability than RA copper, meaning it is less likely to change shape or size when exposed to temperature changes or mechanical stress.

- More consistent thickness: The electrodeposition process allows for very precise control over the thickness of the copper foil, resulting in a more consistent thickness across the entire roll.

- Lower cost: ED copper is generally less expensive to manufacture than RA copper, making it a more cost-effective option for many flex circuit applications.

Applications of ED Copper

ED copper foil is commonly used in flex circuit applications that require:

- High tensile strength

- Excellent dimensional stability

- Consistent thickness

- Cost-effectiveness

Some examples of applications where ED copper is preferred include:

- Consumer electronics

- Automotive electronics

- Industrial control systems

- Telecommunications equipment

Comparison of RA Copper and ED Copper Properties

To better understand the differences between RA copper and ED copper, let’s compare their key properties side by side:

| Property | RA Copper | ED Copper |

|---|---|---|

| Ductility | Higher | Lower |

| Thermal Conductivity | Higher | Lower |

| Electrical Conductivity | Higher | Lower |

| Surface Smoothness | Smoother | Rougher |

| Tensile Strength | Lower | Higher |

| Dimensional Stability | Lower | Higher |

| Thickness Consistency | Lower | Higher |

| Cost | Higher | Lower |

As you can see, both RA copper and ED copper have their strengths and weaknesses. The choice between the two will depend on the specific requirements of your flex circuit application.

Choosing the Right Copper Foil for Your Flex Circuit

When deciding between RA copper and ED copper for your flex circuit design, consider the following factors:

- Flexibility requirements: If your application requires a high degree of flexibility, RA copper may be the better choice due to its higher ductility.

- Thermal management: If your flex circuit needs to dissipate heat efficiently, RA copper’s higher thermal conductivity may make it the preferred option.

- Electrical performance: For applications that demand high electrical conductivity, such as high-frequency circuits, RA copper may be the better choice.

- Mechanical stress: If your flex circuit will be subjected to high levels of mechanical stress or strain, ED copper’s higher tensile strength may make it the more suitable option.

- Dimensional stability: For applications where maintaining precise dimensions is critical, ED copper’s better dimensional stability may be advantageous.

- Cost: If cost is a primary concern, ED copper may be the more cost-effective choice, especially for large-volume production runs.

Ultimately, the best choice of copper foil will depend on a careful analysis of your specific application requirements and design constraints. It’s essential to work closely with your flex circuit manufacturer to select the most suitable copper foil for your project.

FAQ

- Q: Can I use both RA copper and ED copper in the same flex circuit design?

A: Yes, it is possible to use both RA copper and ED copper in a single flex circuit design. This approach is called a hybrid construction and can be useful when different parts of the circuit have different requirements for flexibility, thermal management, or mechanical strength. - Q: What are the typical thicknesses of copper foil used in flex circuits?

A: Copper foil for flex circuits is available in a range of thicknesses, typically from 9 to 175 microns (0.0004 to 0.007 inches). The most common thicknesses are 18, 35, and 70 microns (0.0007, 0.0014, and 0.0028 inches). - Q: How does the choice of copper foil affect the overall cost of a flex circuit?

A: The choice of copper foil can have a significant impact on the overall cost of a flex circuit. ED copper is generally less expensive than RA copper, so using ED copper can help reduce material costs. However, the total cost of the flex circuit will also depend on factors such as the circuit complexity, layer count, and production volume. - Q: Are there any environmental concerns associated with the manufacturing of RA copper or ED copper?

A: Both RA copper and ED copper manufacturing processes have some environmental impact, primarily related to energy consumption and waste generation. However, modern manufacturing facilities employ various strategies to minimize their environmental footprint, such as recycling process water and implementing energy-efficient equipment. - Q: Can I specify the type of copper foil I want to use when ordering flex circuits from a manufacturer?

A: Yes, most flex circuit manufacturers will allow you to specify the type of copper foil you want to use in your design. It’s important to communicate your requirements clearly and work closely with your manufacturer to ensure that the selected copper foil meets your application’s needs.

In conclusion, understanding the differences between RA copper and ED copper is essential for designing high-performance flex circuits. By carefully considering your application requirements and working closely with your flex circuit manufacturer, you can select the most suitable copper foil for your project, ensuring optimal performance, reliability, and cost-effectiveness.

No responses yet