Introduction to High-Tg PCB

High-Tg PCB, or high Glass Transition Temperature printed circuit board, is a type of PCB that uses substrate materials with a glass transition temperature (Tg) higher than standard FR-4 PCBs. The glass transition temperature refers to the temperature range where the PCB substrate transitions from a rigid, glassy state to a softened state.

High-Tg PCBs are designed to maintain their mechanical and electrical properties at elevated temperatures, making them suitable for applications that require high thermal stability and reliability. These PCBs can withstand higher operating temperatures, have better dimensional stability, and exhibit lower thermal expansion compared to standard PCBs.

Key Characteristics of High-Tg PCB

- Elevated Glass Transition Temperature:

- High-Tg PCBs have a glass transition temperature above 170°C (338°F), while standard FR-4 PCBs have a Tg around 130°C (266°F).

-

Higher Tg allows High-Tg PCBs to maintain their structural integrity and performance at higher temperatures.

-

Enhanced Thermal Stability:

- High-Tg PCBs exhibit better thermal stability, meaning they are less prone to warping, twisting, or delamination when exposed to high temperatures.

-

This stability is crucial for applications that generate significant heat or operate in high-temperature environments.

-

Lower Coefficient of Thermal Expansion (CTE):

- High-Tg PCBs have a lower CTE compared to standard PCBs, which means they expand and contract less when subjected to temperature changes.

-

Lower CTE minimizes stress on components and solder joints, improving the reliability and lifespan of the circuit board.

-

Improved Mechanical Strength:

- The high-performance substrate materials used in High-Tg PCBs provide enhanced mechanical strength and rigidity.

- This increased strength makes High-Tg PCBs more resistant to physical stress, vibrations, and impacts.

High-Tg PCB Substrate Materials

High-Tg PCBs are manufactured using specialized substrate materials that offer superior thermal and mechanical properties compared to standard FR-4 materials. Some commonly used High-Tg substrate materials include:

- Polyimide (PI):

- Polyimide is a high-performance polymer known for its excellent thermal stability, with a Tg ranging from 250°C to 400°C (482°F to 752°F).

-

PI-based PCBs are widely used in aerospace, automotive, and military applications that require operation in extreme temperatures.

-

High-Tg FR-4:

- High-Tg FR-4 is an enhanced version of the standard FR-4 material, with a Tg ranging from 170°C to 180°C (338°F to 356°F).

-

It offers improved thermal stability and mechanical strength compared to standard FR-4, making it suitable for a wide range of high-temperature applications.

-

Bismaleimide Triazine (BT):

- BT is a thermoset polymer with a Tg around 210°C (410°F), providing excellent thermal stability and low moisture absorption.

-

BT-based PCBs are commonly used in high-density interconnect (HDI) and chip packaging applications.

-

Cyanate Ester (CE):

- Cyanate ester is a high-performance thermoset resin with a Tg ranging from 250°C to 290°C (482°F to 554°F).

- CE-based PCBs offer superior thermal stability, low dielectric loss, and good chemical resistance, making them suitable for high-frequency and harsh environment applications.

The choice of substrate material for a High-Tg PCB depends on the specific requirements of the application, such as the operating temperature range, mechanical loads, and electrical performance needs.

| Substrate Material | Glass Transition Temperature (Tg) | Key Characteristics |

|---|---|---|

| Polyimide (PI) | 250°C – 400°C (482°F – 752°F) | – Excellent thermal stability – Suitable for extreme temperature applications |

| High-Tg FR-4 | 170°C – 180°C (338°F – 356°F) | – Enhanced thermal stability and mechanical strength compared to standard FR-4 – Widely used in high-temperature applications |

| Bismaleimide Triazine (BT) | 210°C (410°F) | – Good thermal stability and low moisture absorption – Commonly used in HDI and chip packaging |

| Cyanate Ester (CE) | 250°C – 290°C (482°F – 554°F) | – Superior thermal stability and low dielectric loss – Suitable for high-frequency and harsh environments |

Manufacturing Process of High-Tg PCB

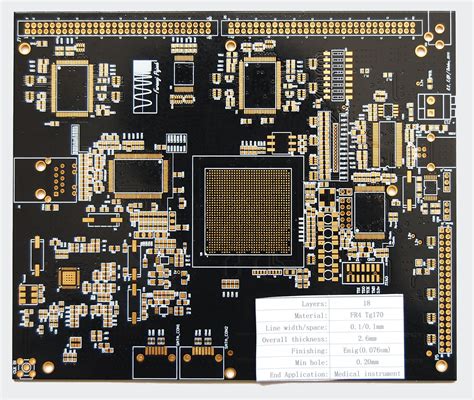

The manufacturing process of High-Tg PCBs is similar to that of standard PCBs, but with some specific considerations and adjustments to accommodate the high-performance substrate materials. The general steps involved in the manufacturing process are as follows:

- Material Selection and Preparation:

- The appropriate High-Tg substrate material is selected based on the application requirements.

-

The substrate material is cut to the desired size and shape, and any necessary pre-treatment or cleaning is performed.

-

Imaging and Etching:

- The circuit design is transferred onto the High-Tg substrate using photolithography or direct imaging techniques.

-

The exposed areas of the substrate are then etched using chemical or plasma etching processes to remove the unwanted copper, creating the desired circuit patterns.

-

Lamination:

- Multiple layers of High-Tg substrate material are laminated together using high-temperature and pressure conditions to form a multilayer PCB.

-

The lamination process ensures proper bonding between layers and maintains the integrity of the circuit patterns.

-

Drilling and Plating:

- Holes are drilled through the laminated High-Tg PCB to accommodate components and interconnections.

-

The drilled holes are then plated with copper to create electrical connections between layers.

-

Solder Mask and Surface Finish Application:

- A solder mask is applied to the High-Tg PCB to protect the copper traces and prevent short circuits.

-

A surface finish, such as ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling), is applied to the exposed copper areas to improve solderability and protect against oxidation.

-

Electrical Testing and Inspection:

- The manufactured High-Tg PCB undergoes rigorous electrical testing to ensure proper functionality and adherence to design specifications.

-

Visual inspections are also performed to check for any manufacturing defects or anomalies.

-

Packaging and Shipping:

- The completed High-Tg PCBs are packaged and shipped to the customer or end-user for assembly and integration into the final product.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the consistency and reliability of the High-Tg PCBs. Special attention is given to the handling and processing of the high-performance substrate materials to maintain their superior thermal and mechanical properties.

Applications of High-Tg PCB

High-Tg PCBs find applications in various industries and sectors where high thermal stability, reliability, and performance are critical. Some common applications of High-Tg PCBs include:

- Automotive Electronics:

- High-Tg PCBs are used in automotive electronics systems, such as engine control units (ECUs), power electronics, and sensors, which are subjected to high temperatures and harsh operating conditions.

-

The thermal stability and reliability of High-Tg PCBs ensure the proper functioning of these critical systems in the demanding automotive environment.

-

Aerospace and Defense:

- Aerospace and defense applications often require PCBs that can withstand extreme temperatures, vibrations, and shocks.

-

High-Tg PCBs are used in avionics systems, radar equipment, satellite communications, and other aerospace and defense electronics that operate in challenging environments.

-

Industrial Equipment and Machinery:

- Industrial equipment and machinery, such as power converters, motor drives, and control systems, generate significant heat during operation.

-

High-Tg PCBs provide the necessary thermal stability and reliability to ensure the long-term performance and durability of these industrial electronics.

-

High-Power LED Lighting:

- High-power LED lighting systems generate substantial heat, which can affect the performance and lifespan of the LEDs and associated electronics.

-

High-Tg PCBs are used in LED lighting applications to dissipate heat effectively and maintain the stability of the circuit board, ensuring optimal LED performance and longevity.

-

Oil and Gas Industry:

- The oil and gas industry involves harsh operating conditions, including high temperatures, pressures, and exposure to corrosive substances.

-

High-Tg PCBs are used in downhole drilling equipment, subsea electronics, and other oil and gas applications to withstand these challenging environments and ensure reliable operation.

-

Medical Devices:

- Certain medical devices, such as surgical equipment and sterilization systems, require PCBs that can withstand high temperatures and maintain performance over extended periods.

-

High-Tg PCBs are used in these medical applications to ensure the reliability and safety of the devices.

-

Telecommunications and Networking:

- High-speed telecommunications and networking equipment, such as routers, switches, and base stations, generate significant heat during operation.

- High-Tg PCBs are used in these applications to provide thermal stability, low dielectric loss, and high-frequency performance, ensuring reliable and efficient data transmission.

These are just a few examples of the diverse applications of High-Tg PCBs. The superior thermal and mechanical properties of High-Tg PCBs make them suitable for any application that demands high reliability, performance, and the ability to withstand challenging operating conditions.

Advantages of High-Tg PCB

High-Tg PCBs offer several advantages over standard PCBs, making them the preferred choice for applications that require high thermal stability and reliability. Some key advantages of High-Tg PCBs include:

- Enhanced Thermal Stability:

- The higher glass transition temperature (Tg) of High-Tg PCBs enables them to maintain their structural integrity and performance at elevated temperatures.

-

This thermal stability reduces the risk of warping, twisting, or delamination, ensuring the reliability and longevity of the circuit board in high-temperature environments.

-

Improved Mechanical Strength:

- The high-performance substrate materials used in High-Tg PCBs provide enhanced mechanical strength and rigidity compared to standard PCBs.

-

This increased strength makes High-Tg PCBs more resistant to physical stress, vibrations, and impacts, reducing the risk of mechanical failures.

-

Lower Coefficient of Thermal Expansion (CTE):

- High-Tg PCBs have a lower CTE, which means they expand and contract less when subjected to temperature changes.

-

The lower CTE minimizes stress on components and solder joints, reducing the risk of cracking, delamination, or other thermal-induced failures.

-

Better Dimensional Stability:

- The enhanced thermal and mechanical properties of High-Tg PCBs contribute to better dimensional stability.

-

This stability ensures that the circuit board maintains its shape and size even under high-temperature conditions, facilitating accurate component placement and reliable interconnections.

-

Increased Reliability and Longer Lifespan:

- The combination of thermal stability, mechanical strength, and lower CTE of High-Tg PCBs results in increased reliability and longer lifespan of the circuit board.

-

High-Tg PCBs are less prone to failures caused by thermal stresses, vibrations, or other environmental factors, reducing the need for frequent replacements or repairs.

-

Compatibility with High-Temperature Components:

- High-Tg PCBs are compatible with components that are designed to operate at high temperatures, such as power electronics, sensors, or high-power LEDs.

-

The thermal stability of High-Tg PCBs ensures that the circuit board can withstand the heat generated by these components without compromising performance or reliability.

-

Suitability for Harsh Environments:

- High-Tg PCBs are well-suited for applications that involve harsh operating conditions, such as extreme temperatures, vibrations, shocks, or exposure to corrosive substances.

-

The superior thermal and mechanical properties of High-Tg PCBs enable them to withstand these challenging environments and maintain reliable performance.

-

Reduced Thermal Management Requirements:

- The enhanced thermal stability of High-Tg PCBs can reduce the need for complex thermal management solutions, such as heatsinks or cooling systems.

-

This can lead to simplified system designs, reduced costs, and improved overall system reliability.

-

Compatibility with Advanced Manufacturing Processes:

- High-Tg PCBs are compatible with advanced manufacturing processes, such as high-density interconnect (HDI) and fine-pitch component assembly.

- The thermal stability and dimensional stability of High-Tg PCBs facilitate the implementation of these advanced processes, enabling the development of compact and high-performance electronic systems.

These advantages make High-Tg PCBs an attractive choice for applications that demand high reliability, performance, and the ability to operate in challenging environments. By leveraging the enhanced thermal and mechanical properties of High-Tg PCBs, designers and engineers can create robust and long-lasting electronic systems that meet the stringent requirements of various industries.

Challenges and Considerations in High-Tg PCB Design and Manufacturing

While High-Tg PCBs offer numerous advantages, there are also some challenges and considerations that need to be addressed during the design and manufacturing process. These challenges and considerations include:

- Material Cost:

- High-Tg substrate materials, such as polyimide or cyanate ester, are generally more expensive than standard FR-4 materials.

-

The higher material cost can impact the overall production cost of High-Tg PCBs, making them less economical for certain applications.

-

Manufacturing Complexity:

- The manufacturing process of High-Tg PCBs requires specialized equipment and processes to handle the high-performance substrate materials.

-

The higher temperatures and pressures involved in the lamination process, as well as the specific handling requirements, can increase the manufacturing complexity compared to standard PCBs.

-

Limited Supplier Options:

- The availability of High-Tg substrate materials and the number of suppliers offering High-Tg PCB manufacturing services may be limited compared to standard PCBs.

-

This limited supplier base can impact lead times, pricing, and sourcing options for High-Tg PCBs.

-

Design Considerations:

- Designing High-Tg PCBs requires careful consideration of the thermal and mechanical properties of the substrate materials.

-

Designers need to account for factors such as the coefficient of thermal expansion (CTE), Thermal Conductivity, and dielectric properties when selecting materials and designing the PCB Layout.

-

Compatibility with Components:

- Not all components are designed to withstand the high temperatures associated with High-Tg PCBs.

-

Designers must carefully select components that are compatible with the thermal requirements of the application and the High-Tg substrate material.

-

Manufacturing Yield:

- The manufacturing yield of High-Tg PCBs may be lower compared to standard PCBs due to the complexity of the manufacturing process and the stringent quality requirements.

-

Lower yields can impact production costs and lead times, requiring careful process control and quality assurance measures.

-

Thermal Management:

- Although High-Tg PCBs offer enhanced thermal stability, proper thermal management is still crucial to ensure reliable operation.

-

Designers need to consider factors such as heat dissipation, thermal interfaces, and cooling mechanisms to effectively manage the heat generated by components on the High-Tg PCB.

-

Testing and Qualification:

- High-Tg PCBs may require additional testing and qualification processes to validate their performance and reliability in the intended application.

-

This can include high-temperature testing, thermal cycling, and other environmental stress tests to ensure the PCB can withstand the expected operating conditions.

-

Manufacturing Considerations:

- The manufacturing process of High-Tg PCBs requires careful control and optimization to ensure consistent quality and reliability.

-

Factors such as drill parameters, etching conditions, and lamination profiles need to be tailored to the specific High-Tg substrate material and application requirements.

-

Repair and Rework Challenges:

- Repairing or reworking High-Tg PCBs can be more challenging compared to standard PCBs due to the high-temperature materials and the potential impact on the PCB’s integrity.

- Specialized repair techniques and equipment may be required to perform repairs or rework on High-Tg PCBs while maintaining their performance and reliability.

Addressing these challenges and considerations requires close collaboration between designers, manufacturers, and end-users. By carefully evaluating the application requirements, selecting appropriate materials and components, and implementing robust design and manufacturing practices, the benefits of High-Tg PCBs can be realized while mitigating

No responses yet