Introduction

Printed Circuit Board (PCB) design is a complex process that requires careful planning, attention to detail, and adherence to best practices. Poor PCB design can lead to a range of issues, from signal integrity problems to manufacturing defects. To help you avoid these issues and create better PCB designs, we’ve compiled a list of 10 essential PCB design rules.

Rule 1: Use Appropriate Track Width and Spacing

One of the most critical aspects of PCB design is choosing the right track width and spacing. The track width determines the current-carrying capacity of the trace, while the spacing between tracks affects signal integrity and manufacturing feasibility.

| Parameter | Minimum Value |

|---|---|

| Track Width | 0.2 mm |

| Track Spacing | 0.2 mm |

It’s essential to consider the current requirements of your circuit when selecting track widths. Wider tracks can carry more current but take up more space on the board. Narrower tracks are more space-efficient but have lower current-carrying capacity.

Best Practices for Track Width and Spacing

- Use appropriate track widths based on current requirements

- Maintain adequate spacing between tracks to avoid signal integrity issues

- Follow the manufacturer’s guidelines for minimum track width and spacing

Rule 2: Keep Signal Traces Short and Direct

Long, meandering signal traces can cause signal integrity issues, such as reflections, crosstalk, and electromagnetic interference (EMI). To minimize these problems, it’s essential to keep signal traces as short and direct as possible.

Best Practices for Signal Trace Routing

- Route signal traces directly from source to destination

- Avoid unnecessary turns and bends in signal traces

- Use appropriate layer transitions for multi-layer boards

Rule 3: Use Ground Planes for Signal Return Paths

Ground planes provide low-impedance return paths for signals, reducing EMI and improving signal integrity. They also help to distribute heat evenly across the board, improving thermal performance.

Best Practices for Ground Planes

- Use solid ground planes whenever possible

- Connect ground planes on different layers using vias

- Avoid splitting ground planes unnecessarily

Rule 4: Decouple Power Supply Lines

Power supply decoupling is essential for reducing noise and ensuring stable power delivery to components. Decoupling capacitors should be placed close to the power pins of ICs to minimize the loop area and reduce the effects of parasitic inductance.

Best Practices for Power Supply Decoupling

- Use appropriate decoupling capacitor values based on the frequency range of the circuit

- Place decoupling capacitors as close to IC power pins as possible

- Use multiple decoupling capacitors in parallel for better high-frequency performance

Rule 5: Minimize Crosstalk

Crosstalk occurs when signals from one trace couple onto adjacent traces, causing signal integrity issues. To minimize crosstalk, it’s essential to maintain adequate spacing between signal traces and route them perpendicularly when they must cross.

Best Practices for Minimizing Crosstalk

- Maintain adequate spacing between signal traces

- Route signal traces perpendicularly when they must cross

- Use guard traces or ground planes between sensitive signal traces

Rule 6: Consider Thermal Management

Thermal management is crucial for ensuring the reliability and longevity of your PCB. Poor thermal design can lead to component overheating, reduced performance, and premature failure.

Best Practices for Thermal Management

- Use appropriate copper pour for heat dissipation

- Place high-power components away from temperature-sensitive components

- Use thermal vias to conduct heat away from components

Rule 7: Follow Manufacturer’s Guidelines

Different PCB manufacturers have different capabilities and requirements. It’s essential to follow the manufacturer’s guidelines for design rules, such as minimum track width, spacing, and hole sizes, to ensure that your board can be manufactured reliably and cost-effectively.

Best Practices for Following Manufacturer’s Guidelines

- Obtain the manufacturer’s design rule document before starting your design

- Verify that your design complies with the manufacturer’s guidelines before submitting for production

- Communicate with your manufacturer if you have any questions or concerns

Rule 8: Use Appropriate Via Sizes and Spacing

Vias are used to connect traces on different layers of a multi-layer PCB. Choosing the right via size and spacing is essential for ensuring reliable connections and minimizing manufacturing issues.

| Parameter | Minimum Value |

|---|---|

| Via Diameter | 0.4 mm |

| Via Spacing | 0.4 mm |

Best Practices for Via Sizes and Spacing

- Use appropriate via sizes based on the current requirements and layer count of your board

- Maintain adequate spacing between vias to avoid manufacturing issues

- Follow the manufacturer’s guidelines for minimum via size and spacing

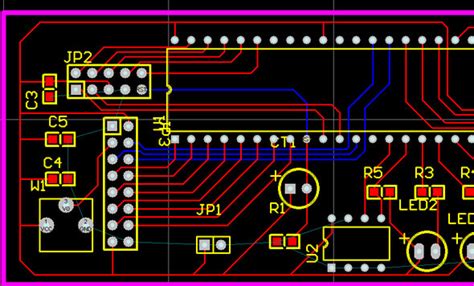

Rule 9: Consider Component Placement

Component placement is critical for ensuring proper functionality, signal integrity, and manufacturability of your PCB. Poor component placement can lead to signal integrity issues, thermal problems, and difficulties in assembly.

Best Practices for Component Placement

- Place components logically based on their function and interconnections

- Consider the mechanical constraints of your enclosure when placing components

- Leave adequate space around components for assembly and rework

Rule 10: Perform Design Reviews and Verification

Before sending your PCB design for manufacturing, it’s essential to perform thorough design reviews and verification. This helps to catch any errors or potential issues early in the design process, saving time and money in the long run.

Best Practices for Design Reviews and Verification

- Use PCB design software with built-in design rule checks (DRC)

- Have your design reviewed by an experienced PCB designer

- Perform signal integrity simulations to verify the performance of critical signals

Frequently Asked Questions (FAQ)

1. What is the minimum track width and spacing I should use for my PCB?

The minimum track width and spacing depend on the capabilities of your PCB manufacturer. As a general guideline, a minimum track width and spacing of 0.2 mm is achievable by most manufacturers. However, it’s always best to consult your manufacturer’s design guidelines for specific requirements.

2. How important is power supply decoupling in PCB design?

Power supply decoupling is critical for ensuring stable power delivery to components and reducing noise in your circuit. Inadequate decoupling can lead to signal integrity issues, reduced performance, and even component damage. It’s essential to use appropriate decoupling capacitor values and placement for optimal performance.

3. What are some best practices for minimizing crosstalk in PCB design?

To minimize crosstalk, maintain adequate spacing between signal traces and route them perpendicularly when they must cross. You can also use guard traces or ground planes between sensitive signal traces to reduce coupling. Additionally, keep signal traces as short and direct as possible to minimize the potential for crosstalk.

4. How can I ensure good thermal management in my PCB design?

To ensure good thermal management, use appropriate copper pour for heat dissipation and place high-power components away from temperature-sensitive components. You can also use thermal vias to conduct heat away from components and into the ground planes or heatsinks. Consider the thermal requirements of your components and the operating environment when designing your PCB.

5. Why is it important to follow the manufacturer’s design guidelines?

Different PCB manufacturers have different capabilities and requirements. Following the manufacturer’s design guidelines ensures that your PCB can be manufactured reliably and cost-effectively. Noncompliance with these guidelines can lead to manufacturing issues, delays, and additional costs. Always obtain and follow the manufacturer’s design rule document and communicate with them if you have any questions or concerns.

Conclusion

Designing a high-quality PCB requires attention to detail and adherence to best practices. By following these 10 essential PCB design rules, you can avoid common issues and ensure that your board performs reliably and meets your requirements. Remember to consider signal integrity, thermal management, manufacturability, and design verification throughout the design process. With careful planning and execution, you can create PCBs that are robust, reliable, and ready for production.

No responses yet