Introduction to Stencil Printing Resolution

Stencil printing is a popular method for depositing solder paste onto printed circuit boards (PCBs) for surface mount assembly. The resolution and accuracy of the stencil printing process directly impacts the quality and reliability of the assembled PCBs.

The Rayming stencil-mate is a widely used stencil printer that offers high precision solder paste printing capabilities. One of the key specifications of any stencil printer is the component printing resolution it can achieve. This refers to the smallest sized components the printer can accurately print solder paste deposits for.

In this article, we will explore the printing resolution capabilities of the Rayming stencil-mate in detail. We’ll cover the factors that affect stencil printing resolution, the specific resolutions the Rayming printer can achieve, and tips for optimizing print quality when working with small components.

Factors That Determine Stencil Printing Resolution

Several variables influence the minimum component size and pitch that can be successfully printed with a stencil printer. The main factors include:

Stencil Thickness

The stencil foil thickness used has a big impact on printing resolution. Thinner stencils in the range of 3-4 mils allow printing of smaller apertures for fine-pitch components compared to thicker 5-6 mil stencils. However, thinner stencils are also more prone to wear and damage.

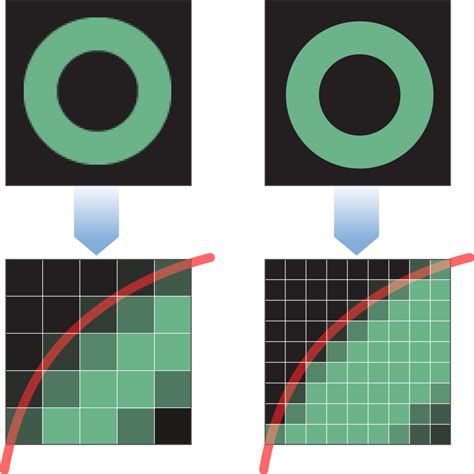

Aperture Size and Shape

The size and shape of the stencil apertures need to be optimized based on the component size and required solder paste volume. The aperture should be slightly larger than the component pad to allow a clean paste release. Smaller apertures are needed for smaller chip components and fine-pitch QFPs & BGAs.

Solder Paste Particle Size

The particle size of the solder paste also affects printability. Type 3 paste with 25-45 µm particles is typically used for standard SMT printing. However, for fine-pitch components, Type 4 or 5 paste with smaller particles in the range of 20-25 µm allows printing through smaller apertures.

Squeegee Blade

The hardness, edge quality, and material of the squeegee blade influence the paste deposition. Metal squeegee blades provide better printing resolution than polyurethane blades. The blade edge must be sharp and free of nicks or dents.

Print Parameters

Print speed, pressure, snapoff distance and separation speed also affect the resolution. Slower speeds, lower pressures, smaller snapoff, and faster separation aid in printing smaller deposits. The parameters need to be optimized based on the stencil and paste being used.

Rayming Stencil-Mate Printing Resolution

The Rayming stencil-mate printers are capable of achieving fine resolution prints for small chip components and fine-pitch ICs. Let’s look at the specific component sizes and pitches it can print.

Chip Components

For standard chip components sizes 0402 (1005 metric) and larger, the Rayming can easily print using a Type 3 paste and a 4-5 mil stencil with high reproducibility.

For 0201 (0603 metric) chip components, a 3-4 mil stencil with Type 4 paste provides good results.

Going down to 01005 (0402 metric) chips is possible with a 3 mil stencil and Type 5 paste, but requires careful optimization of the print parameters and a high-quality stencil. A 0.4-0.5 area ratio between the aperture and pad size is recommended.

The table below summarizes the recommended stencil and paste for printing various chip sizes:

| Component Size | Stencil Thickness | Solder Paste Type |

|---|---|---|

| 0603 and larger | 4-5 mil | Type 3 |

| 0402 | 4 mil | Type 3 |

| 0201 | 3-4 mil | Type 4 |

| 01005 | 3 mil | Type 5 |

Quad-Flat Packages (QFP)

QFPs with lead pitches down to 0.4mm can be printed using the Rayming printer with a 4 mil stencil and Type 3 paste.

For finer pitches between 0.3-0.4mm, a 3-4 mil stencil with Type 4 paste is recommended. The aperture width should be around 85-90% of the lead pitch.

Printing QFPs with 0.3mm pitch and below requires a high quality 3 mil stencil along with Type 5 paste. Special aperture designs like window panes may be needed to achieve sufficient paste volume.

See the table below for QFP printing recommendations:

| QFP Lead Pitch | Stencil Thickness | Solder Paste Type | Aperture Width |

|---|---|---|---|

| 0.5mm and above | 4-5 mil | Type 3 | 90% of pitch |

| 0.4mm | 4 mil | Type 3 | 90% of pitch |

| 0.3-0.4mm | 3-4 mil | Type 4 | 85-90% of pitch |

| Below 0.3mm | 3 mil | Type 5 | Custom aperture |

Ball Grid Arrays (BGA)

BGAs are one of the most challenging components to print due to their high pin count and small solder ball pitches.

With the Rayming stencil-mate, BGAs with 0.8mm pitch can be printed with a 4-5 mil stencil and Type 3 paste. Reducing the pitch to 0.5mm requires switching to a thinner 4 mil stencil.

For pitches between 0.4-0.5mm, a 3-4 mil stencil is needed along with Type 4 solder paste. Spherical apertures provide the best paste release for BGA pads.

Printing 0.4mm and finer pitch BGAs requires a 3 mil stencil and Type 5 paste to achieve the small deposits needed. A high quality laser-cut, electropolished stencil is a must for this resolution.

The following table lists the BGA pitch printing guidelines:

| BGA Pitch | Stencil Thickness | Solder Paste Type |

|---|---|---|

| 0.8mm | 4-5 mil | Type 3 |

| 0.5-0.8mm | 4 mil | Type 3 |

| 0.4-0.5mm | 3-4 mil | Type 4 |

| Below 0.4mm | 3 mil | Type 5 |

Tips for Optimizing Fine-Pitch Printing

To achieve the best print quality when using the Rayming stencil-mate for small components, follow these guidelines:

-

Always use a high quality, fine grain stencil with smooth aperture walls for fine-pitch printing. Laser-Cut Stencils provide the best resolution.

-

Inspect the stencil for any damage or aperture blockage prior to printing. Repair or replace stencils as needed.

-

Select the solder paste type based on the required resolution. Use Type 4 paste for 0201 chips and 0.3-0.4mm pitch QFPs/BGAs. Switch to Type 5 for 01005 chips and <0.3mm pitch ICs.

-

Optimize the print parameters, especially print speed, pressure and separation speed. Use slower speeds and lower pressures than normal. A snapoff between 0.01-0.05″ and separation speeds >0.5″/sec aid paste release.

-

Maintain a consistent paste viscosity and minimize stencil cleaning cycles. Insufficient cleaning leads to aperture clogging while excessive underside cleaning dries out the paste.

-

Verify the print quality frequently by using a paste height inspection system. Make sure the paste deposits meet the target height and volume.

-

Consider using stepped stencils or special aperture designs for heavily populated PCBs with both large and fine-pitch components.

Conclusion

In summary, the Rayming stencil-mate is a versatile printer that can print components as small as 01005 chips and 0.3mm pitch CSPs when paired with the right stencil design and solder paste.

By selecting an appropriate stencil thickness, aperture size, and paste type based on the component pitch, and optimizing the print parameters, consistent fine-pitch printing is achievable.

As component miniaturization continues to advance, innovations in stencil and solder paste technology will be key to enhancing the printing resolution and expanding the capabilities of the Rayming and other stencil printers. Staying up to date with these developments will be essential for meeting future electronics assembly challenges.

FAQ

What is the smallest chip component size the Rayming stencil-mate can print?

The Rayming can print 01005 (0402 metric) chip components with a 3 mil stencil and Type 5 solder paste. However, printing 01005 chips requires careful optimization of the aperture design and print parameters to achieve consistent results.

How thin of a stencil is needed for fine-pitch QFPs and BGAs?

In general, a 3-4 mil thick stencil is recommended for printing QFPs and BGAs with 0.3-0.5mm lead/ball pitches. The finer the pitch, the thinner the stencil needs to be to achieve the small aperture sizes and paste deposits required.

Can the Rayming print solder paste for 0.3mm pitch CSPs?

Yes, the Rayming stencil-mate can print 0.3mm pitch chip-scale packages (CSPs) by using a high quality 3 mil laser-cut stencil along with a Type 5 solder paste. Specialized aperture shapes may be needed to get enough paste volume on the small pads.

What are the key factors to consider when printing small chip components?

The main factors to consider for fine-pitch chip printing are the stencil thickness, aperture size and shape, solder paste type, and print parameters like print speed, pressure and separation speed. A smooth, thin stencil, smaller particle size paste, and optimized print parameters are critical for achieving good results.

How often should print quality be checked when printing fine-pitch components?

Print quality should be checked frequently, ideally every 1-2 print cycles, when working with fine-pitch components. Verifying the paste deposit height, volume, and shape consistency with an SPI system helps catch any print issues early and prevents defects down the line. Continuous monitoring of the paste viscosity and regular stencil cleaning are also important.

No responses yet