Introduction to Gerber Files

Gerber files are a standard file format used in the printed circuit board (PCB) industry to describe the layout and design of a PCB. They are named after the Gerber Scientific Instrument Company, which developed the format in the 1960s. Gerber files are essential for manufacturing PCBs as they contain all the necessary information for the PCB fabrication process.

Types of Gerber Files

There are two main types of Gerber files:

-

Standard Gerber (RS-274X): This is the original Gerber file format, which has been widely used since the 1980s. It consists of a set of ASCII text files, each representing a different layer of the PCB, such as copper, solder mask, and silkscreen.

-

Extended Gerber (RS-274X): Also known as Gerber X or Gerber X2, this is an enhanced version of the standard Gerber format. It was introduced in 1998 and includes additional features and capabilities to address the limitations of the standard Gerber format.

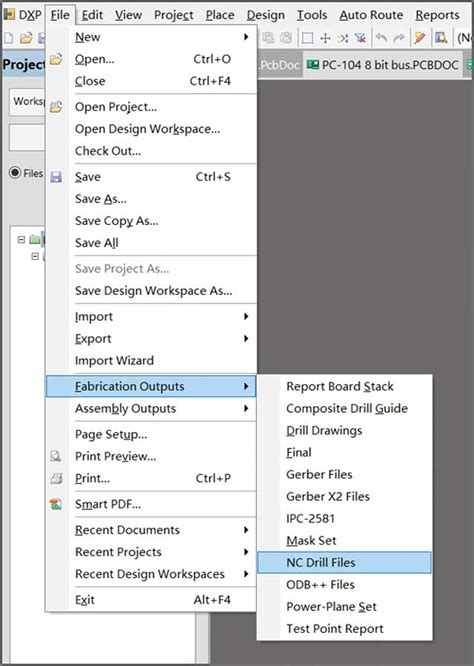

Gerber X2 Files

Gerber X2 is the latest revision of the Gerber file format, released in 2014. It builds upon the foundation of Extended Gerber (RS-274X) and introduces several new features and improvements to streamline the PCB manufacturing process.

Key Features of Gerber X2

-

Embedded Aperture Definitions: In Gerber X2, aperture definitions are embedded within the Gerber file itself, eliminating the need for separate aperture list files. This simplifies file management and reduces the chances of errors.

-

Attribute Data: Gerber X2 allows the inclusion of attribute data, such as part numbers, reference designators, and component descriptions, directly within the Gerber file. This information can be used by PCB fabrication and assembly software to automate certain processes and improve efficiency.

-

Nested Step and Repeat: Gerber X2 introduces the concept of nested step and repeat, which allows for the creation of complex panel layouts with multiple levels of repeating patterns. This feature simplifies the panelization process and reduces the file size compared to standard Gerber.

-

Improved Copper Pours: Gerber X2 provides better support for copper pours, including the ability to define unique apertures for different copper pour areas. This allows for more precise control over the copper distribution on the PCB.

-

Enhanced Arcs and Curves: Gerber X2 includes support for multi-quadrant arcs and splines, enabling the creation of more complex and smooth curves in the PCB design.

Comparison of Gerber and Gerber X2 Files

| Feature | Standard Gerber (RS-274X) | Extended Gerber (RS-274X) | Gerber X2 |

|---|---|---|---|

| Aperture Definitions | Separate aperture list file | Separate aperture list file | Embedded within the Gerber file |

| Attribute Data | Not supported | Not supported | Supported |

| Step and Repeat | Single-level | Single-level | Nested multi-level |

| Copper Pours | Limited control | Limited control | Enhanced control with unique apertures |

| Arcs and Curves | Single-quadrant arcs | Single-quadrant arcs | Multi-quadrant arcs and splines |

As shown in the table above, Gerber X2 offers several advantages over the standard and extended Gerber formats. The embedded aperture definitions, attribute data support, nested step and repeat, improved copper pours, and enhanced arcs and curves capabilities make Gerber X2 a more efficient and powerful format for describing PCB designs.

Backward Compatibility

One important aspect to consider when comparing Gerber and Gerber X2 files is backward compatibility. While Gerber X2 introduces new features and improvements, it is designed to be backward compatible with the standard and extended Gerber formats. This means that PCB fabrication software and hardware that support standard and extended Gerber files can still process Gerber X2 files, albeit without taking advantage of the new features.

However, it is essential to ensure that all the software tools used in the PCB design and manufacturing process support Gerber X2 to fully benefit from its capabilities. This includes PCB design software, CAM (Computer-Aided Manufacturing) software, and PCB fabrication equipment.

Adopting Gerber X2 in the PCB Industry

The adoption of Gerber X2 in the PCB industry has been gradual, as it requires updates to existing software tools and manufacturing processes. However, many PCB design software packages and fabrication houses now support Gerber X2, recognizing its benefits in streamlining the PCB manufacturing process and reducing errors.

Benefits of Adopting Gerber X2

-

Simplified File Management: With embedded aperture definitions and attribute data, Gerber X2 files are self-contained and more manageable, reducing the chances of errors caused by mismatched or missing files.

-

Improved Automation: The inclusion of attribute data in Gerber X2 files enables better automation in the PCB fabrication and assembly processes, leading to increased efficiency and reduced turnaround times.

-

Enhanced Design Capabilities: Gerber X2’s support for nested step and repeat, improved copper pours, and enhanced arcs and curves allows for more complex and sophisticated PCB designs.

-

Reduced Errors: By providing a more comprehensive and standardized format for describing PCB designs, Gerber X2 helps reduce errors and misinterpretations during the PCB manufacturing process.

Challenges in Adopting Gerber X2

-

Software and Hardware Updates: Adopting Gerber X2 requires updating PCB design software, CAM software, and fabrication equipment to support the new format. This can be a time-consuming and costly process for some companies.

-

Learning Curve: PCB designers and engineers need to familiarize themselves with the new features and capabilities of Gerber X2, which may require additional training and education.

-

Legacy Designs: Existing PCB designs that use standard or extended Gerber files may need to be updated or converted to Gerber X2 to take advantage of its benefits, which can be a significant undertaking for companies with large portfolios of legacy designs.

FAQ

-

Q: Can I use Gerber X2 files with older PCB fabrication software and equipment?

A: Yes, Gerber X2 files are backward compatible with software and equipment that support standard and extended Gerber formats. However, the new features and capabilities of Gerber X2 may not be utilized in such cases. -

Q: Do I need to convert my existing standard Gerber files to Gerber X2?

A: It is not mandatory to convert existing standard Gerber files to Gerber X2. However, converting to Gerber X2 can help you take advantage of its enhanced features and benefits, such as embedded aperture definitions and attribute data support. -

Q: Are there any limitations to using Gerber X2 files?

A: The main limitation of using Gerber X2 files is the requirement for compatible software and hardware. To fully benefit from Gerber X2’s features, all the tools used in the PCB design and manufacturing process must support the format. -

Q: Will using Gerber X2 files increase the cost of PCB fabrication?

A: Generally, using Gerber X2 files should not increase the cost of PCB fabrication. In fact, the improved efficiency and reduced errors associated with Gerber X2 may lead to cost savings in the long run. -

Q: How can I learn more about Gerber X2 and its implementation in my PCB design workflow?

A: There are several resources available to learn more about Gerber X2, including online tutorials, webinars, and workshops conducted by PCB design software vendors and industry associations. Additionally, consulting with your PCB fabrication partner can provide valuable insights into implementing Gerber X2 in your specific design workflow.

Conclusion

Gerber X2 represents a significant advancement in the PCB design and manufacturing process, offering numerous benefits over the standard and extended Gerber formats. With its embedded aperture definitions, attribute data support, nested step and repeat capabilities, improved copper pours, and enhanced arcs and curves, Gerber X2 streamlines the PCB fabrication process and reduces the chances of errors.

While adopting Gerber X2 may require updates to existing software tools and manufacturing processes, the long-term benefits of increased efficiency, reduced errors, and enhanced design capabilities make it a worthwhile investment for companies in the PCB industry. As more PCB design software packages and fabrication houses support Gerber X2, its adoption is expected to grow, leading to a more standardized and efficient PCB manufacturing process.

No responses yet