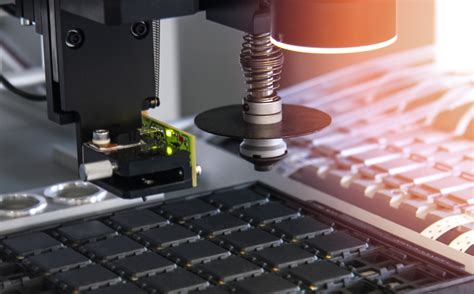

Introduction to PCB Soldering

PCB (Printed Circuit Board) soldering is a crucial process in the manufacturing of electronic devices. It involves the attachment of electronic components to the PCB using a molten metal alloy, typically a tin-lead alloy or lead-free solder. The soldering process creates electrical connections between the components and the copper traces on the PCB, enabling the flow of electrical signals and power throughout the circuit.

Importance of Proper PCB Soldering

Proper PCB soldering is essential for several reasons:

- Reliability: Well-soldered connections ensure the reliable operation of the electronic device, minimizing the risk of failures due to poor connections.

- Durability: Correctly soldered joints can withstand mechanical stress and vibrations, increasing the device’s longevity.

- Performance: Proper soldering techniques minimize signal loss and interference, contributing to optimal device performance.

- Safety: Poorly soldered connections can lead to short circuits, overheating, or other safety hazards.

Problems to Consider When Drawing PCB for Soldering

When designing a PCB Layout for soldering, several potential problems should be taken into account to ensure a successful and efficient soldering process. Let’s explore these issues in detail.

1. Pad Size and Spacing

One of the primary considerations when drawing a PCB for soldering is the size and spacing of the component pads. Pads that are too small or too close together can make soldering difficult and increase the risk of solder bridges (unintended connections between adjacent pads).

Recommended Pad Sizes

| Component Type | Minimum Pad Size (mm) | Recommended Pad Size (mm) |

|---|---|---|

| Resistors | 0.8 x 1.2 | 1.0 x 1.5 |

| Capacitors | 0.8 x 1.2 | 1.0 x 1.5 |

| ICs (SOIC) | 0.6 x 2.0 | 0.8 x 2.5 |

| ICs (QFP) | 0.4 x 1.0 | 0.5 x 1.2 |

To avoid soldering issues, follow these guidelines:

- Use appropriate pad sizes based on the component type and size (refer to the table above).

- Maintain sufficient spacing between pads to prevent solder bridges. A minimum spacing of 0.2 mm is recommended for most components.

- Consider the soldering method (hand soldering or reflow soldering) when determining pad sizes and spacing.

2. Thermal Considerations

Thermal management is another critical factor to consider when designing a PCB for soldering. Excessive heat during the soldering process can damage components or cause the PCB substrate to warp or delaminate.

Thermal Relief Pads

To mitigate thermal issues, incorporate thermal relief pads in your PCB design. Thermal relief pads are small, spoke-like connections between the component pad and the surrounding copper pour. They help dissipate heat during soldering, reducing the risk of thermal damage.

| Thermal Relief Pad Parameter | Recommended Value |

|---|---|

| Spoke Width | 0.25 – 0.5 mm |

| Spoke Length | 0.5 – 1.0 mm |

| Number of Spokes | 4 |

Follow these tips for effective thermal management:

- Use thermal relief pads for components connected to large copper pours or planes.

- Adjust the thermal relief pad parameters based on the component size and the amount of heat generated during soldering.

- Consider using a lower soldering temperature or a shorter soldering time for temperature-sensitive components.

3. Solder Mask Design

Solder mask is a protective coating applied to the PCB surface, exposing only the areas intended for soldering. Proper solder mask design is crucial for achieving reliable soldered connections and preventing solder bridges.

Solder Mask Clearance

Solder mask clearance refers to the gap between the edge of the copper pad and the opening in the solder mask. Insufficient Solder mask clearance can lead to poor solder wetting and weak connections.

| Solder Mask Clearance Parameter | Recommended Value |

|---|---|

| Minimum Clearance | 0.1 mm |

| Ideal Clearance | 0.15 – 0.2 mm |

Consider these points when designing solder mask:

- Ensure adequate solder mask clearance around component pads to allow for proper solder wetting.

- Avoid solder mask between closely spaced pads to prevent solder bridges.

- Use solder mask dams between pads to contain the solder and prevent bridging.

4. Component Placement

The placement of components on the PCB can significantly impact the soldering process. Improper component placement can lead to difficulties in accessing the pads for soldering, increased risk of solder bridges, and potential thermal issues.

Component orientation and Spacing

When placing components on the PCB, consider the following:

- Orient components in a way that allows easy access to the pads for soldering.

- Maintain sufficient spacing between components to accommodate soldering tools and prevent inadvertent contact.

- Group components with similar heights and soldering requirements to optimize the soldering process.

- Place temperature-sensitive components away from high-heat sources during soldering.

5. Silkscreen and Labels

Silkscreen is the text and graphics printed on the PCB surface to provide information about component placement, orientation, and identification. Clear and accurate silkscreen labels are essential for efficient and error-free soldering.

Silkscreen Guidelines

Follow these guidelines for effective silkscreen design:

- Use clear and legible fonts for component labels and values.

- Ensure adequate spacing between silkscreen elements and component pads to avoid confusion.

- Provide polarity indications for polarized components (e.g., electrolytic capacitors, diodes).

- Include any necessary soldering instructions or warnings on the silkscreen.

FAQs

- What is the recommended minimum pad size for resistors and capacitors?

-

The recommended minimum pad size for resistors and capacitors is 0.8 x 1.2 mm. However, a slightly larger pad size of 1.0 x 1.5 mm is preferred for easier soldering and better connection reliability.

-

How do thermal relief pads help in PCB soldering?

-

Thermal relief pads help dissipate heat during the soldering process, reducing the risk of thermal damage to components and the PCB substrate. They are small, spoke-like connections between the component pad and the surrounding copper pour, allowing heat to flow away from the pad more efficiently.

-

What is solder mask clearance, and why is it important?

-

Solder mask clearance refers to the gap between the edge of the copper pad and the opening in the solder mask. It is important because insufficient solder mask clearance can lead to poor solder wetting and weak connections. The recommended minimum clearance is 0.1 mm, with an ideal clearance of 0.15 – 0.2 mm.

-

How does component placement affect PCB soldering?

-

Component placement can impact the accessibility of pads for soldering, the risk of solder bridges, and potential thermal issues. It is important to orient components in a way that allows easy access to the pads, maintain sufficient spacing between components, group components with similar soldering requirements, and place temperature-sensitive components away from high-heat sources.

-

What should be included in the silkscreen design for effective PCB soldering?

- The silkscreen design should include clear and legible fonts for component labels and values, adequate spacing between silkscreen elements and component pads, polarity indications for polarized components, and any necessary soldering instructions or warnings. This information helps ensure efficient and error-free soldering.

Conclusion

Designing a PCB for soldering requires careful consideration of various factors to ensure reliable connections, optimal performance, and longevity of the electronic device. By paying attention to pad size and spacing, thermal management, solder mask design, component placement, and silkscreen labels, you can minimize soldering problems and achieve a successful PCB Assembly.

Remember to follow the recommended guidelines for each aspect of PCB design, and always consider the specific requirements of your components and the intended soldering method. With a well-designed PCB layout, you can streamline the soldering process, reduce the risk of errors, and create high-quality electronic devices.

No responses yet