1. Assess the Manufacturer’s Experience and Expertise

When searching for an SMT manufacturer, it is essential to consider their experience and expertise in the field. Look for manufacturers that have been in the industry for several years and have a proven track record of delivering high-quality products. Experienced manufacturers are more likely to have the knowledge, skills, and resources necessary to handle complex projects and meet strict quality standards.

Evaluating an SMT Manufacturer’s Experience

To evaluate an SMT manufacturer’s experience, consider the following factors:

- Number of years in the industry

- Types of projects they have handled

- Industries they have served

- Certifications and accreditations they have earned

An experienced SMT manufacturer should be able to provide references and case studies that demonstrate their expertise and ability to deliver successful projects. They should also have a deep understanding of the latest technologies, trends, and best practices in SMT manufacturing.

2. Check for Quality Certifications and Standards Compliance

Quality is a critical factor when choosing an SMT manufacturer. To ensure that you receive high-quality products, look for manufacturers that have earned relevant certifications and comply with industry standards. Some of the essential certifications and standards in the SMT industry include:

- ISO 9001: Quality Management System

- IPC-A-610: Acceptability of Electronic Assemblies

- IPC-A-600: Acceptability of Printed Boards

- J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies

- ANSI/ESD S20.20: Protection of Electrical and Electronic Parts, Assemblies, and Equipment

Manufacturers that have earned these certifications demonstrate their commitment to quality and adherence to industry best practices. They undergo regular audits and assessments to maintain their certifications, ensuring that their processes and products consistently meet the required standards.

Benefits of Working with Certified SMT Manufacturers

Working with certified SMT manufacturers offers several benefits, including:

- Consistent and reliable product quality

- Reduced risk of defects and failures

- Faster turnaround times due to streamlined processes

- Improved customer satisfaction and loyalty

- Competitive advantage in the market

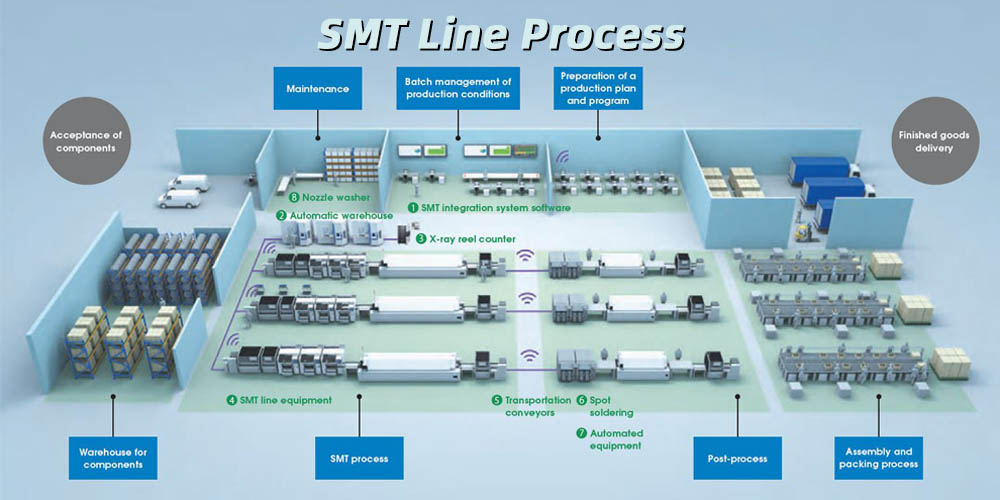

3. Evaluate the Manufacturer’s Production Capabilities

When selecting an SMT manufacturer, it is crucial to ensure that their production capabilities align with your project requirements. Consider factors such as the manufacturer’s production capacity, equipment, and technology to determine whether they can handle your project effectively.

Production Capacity

Assess the manufacturer’s production capacity to ensure that they can meet your volume requirements. Consider both their current capacity and their ability to scale up production if needed. A manufacturer with limited capacity may struggle to deliver large orders on time, leading to delays and potential supply chain disruptions.

Equipment and Technology

Evaluate the manufacturer’s equipment and technology to ensure that they have the necessary tools and resources to produce high-quality SMT assemblies. Look for manufacturers that invest in state-of-the-art equipment, such as:

- Automated Pick-and-Place machines

- Reflow Soldering ovens

- Automated optical inspection (AOI) systems

- X-ray inspection machines

- In-circuit testing (ICT) equipment

Advanced equipment and technology enable manufacturers to achieve higher precision, faster production speeds, and better quality control, ultimately resulting in superior products.

4. Consider the Manufacturer’s Location and Supply Chain

The location of an SMT manufacturer and their supply chain can have a significant impact on your project’s success. When evaluating potential manufacturers, consider factors such as proximity to your business, shipping and logistics, and the stability of their supply chain.

Proximity to Your Business

Working with a manufacturer located close to your business can offer several advantages, such as:

- Faster shipping times and lower transportation costs

- Easier communication and collaboration

- Ability to visit the manufacturing facility for inspections and meetings

However, in some cases, working with an overseas manufacturer may be more cost-effective or provide access to specialized expertise. When considering an overseas manufacturer, evaluate factors such as time zone differences, language barriers, and cultural differences that may impact communication and project management.

Shipping and Logistics

Assess the manufacturer’s shipping and logistics capabilities to ensure that they can deliver products to your location efficiently and reliably. Consider factors such as:

- Shipping methods and carriers

- Customs clearance and documentation

- Packaging and labeling

- Tracking and traceability

A manufacturer with a well-established shipping and logistics process can help minimize delays, reduce the risk of damage during transit, and ensure timely delivery of your products.

Supply Chain Stability

Evaluate the stability of the manufacturer’s supply chain to mitigate the risk of disruptions and delays. A stable supply chain ensures that the manufacturer has access to the necessary components, materials, and resources to complete your project on time. Consider factors such as:

- Relationships with suppliers and vendors

- Inventory management and stock levels

- Contingency plans for supply chain disruptions

- Transparency and communication regarding supply chain issues

5. Assess the Manufacturer’s Customer Service and Support

Choosing an SMT manufacturer with excellent customer service and support can make a significant difference in the success of your project. Good customer service ensures that you have a reliable partner who is responsive to your needs, proactive in addressing issues, and committed to your success.

Communication and Responsiveness

Evaluate the manufacturer’s communication and responsiveness during the initial inquiry and quotation process. A manufacturer who is prompt in responding to your questions, provides clear and detailed information, and is willing to address your concerns is more likely to maintain good communication throughout the project.

Technical Support and Problem-Solving

Assess the manufacturer’s technical support and problem-solving capabilities. Look for manufacturers who have a dedicated technical support team with the knowledge and expertise to address any issues that may arise during the manufacturing process. They should be proactive in identifying potential problems and proposing solutions to minimize the impact on your project timeline and budget.

Flexibility and Customization

Consider the manufacturer’s flexibility and willingness to accommodate your specific requirements and customization needs. A manufacturer who is open to adapting their processes, materials, or designs to meet your unique specifications demonstrates a commitment to customer satisfaction and long-term Partnerships.

6. Request Quotes and Samples from Multiple Manufacturers

Before making a final decision, it is essential to request quotes and samples from multiple SMT manufacturers. This process allows you to compare prices, quality, and service levels to ensure that you select the best manufacturer for your project.

Requesting Quotes

When requesting quotes from SMT manufacturers, provide detailed information about your project requirements, including:

- Bill of Materials (BOM)

- Gerber Files and design specifications

- Quantity and delivery schedule

- Quality and testing requirements

- Packaging and shipping instructions

Providing comprehensive information enables manufacturers to provide accurate and competitive quotes that reflect your specific needs.

Evaluating Samples

Request samples from shortlisted manufacturers to assess the quality of their products firsthand. When evaluating samples, consider factors such as:

- Workmanship and attention to detail

- Conformance to design specifications

- Functionality and performance

- Packaging and labeling

Evaluating samples allows you to verify that the manufacturer can deliver products that meet your quality standards and expectations.

Frequently Asked Questions (FAQ)

- What is the minimum order quantity (MOQ) for SMT manufacturing?

MOQs vary among manufacturers and depend on factors such as the complexity of the project, component availability, and production setup costs. Some manufacturers may offer low MOQs for prototyping or small-batch production, while others may require higher MOQs for cost-effective production. It is essential to discuss MOQ requirements with potential manufacturers to ensure that they align with your project needs. - How long does it typically take to receive a quote from an SMT manufacturer?

The time required to receive a quote from an SMT manufacturer depends on the complexity of the project and the manufacturer’s responsiveness. In general, you can expect to receive a quote within 1-5 business days after submitting your request. However, for more complex projects or during peak seasons, it may take longer. To expedite the quoting process, ensure that you provide comprehensive and accurate information about your project requirements. - What is the typical lead time for SMT manufacturing?

Lead times for SMT manufacturing vary depending on factors such as the complexity of the project, the manufacturer’s production capacity, and the availability of components and materials. Typical lead times range from 2-8 weeks, but can be longer for complex projects or during periods of high demand. To ensure timely delivery, discuss lead time expectations with potential manufacturers and plan your project accordingly. - How can I ensure the confidentiality of my intellectual property when working with an SMT manufacturer?

To protect your intellectual property when working with an SMT manufacturer, consider the following steps: - Sign a non-disclosure agreement (NDA) with the manufacturer before sharing sensitive information

- Limit access to confidential information to only essential personnel

- Encrypt and password-protect sensitive files before sharing them with the manufacturer

- Conduct background checks and due diligence on the manufacturer to assess their reputation and track record

- What should I do if I encounter quality issues with the products received from an SMT manufacturer?

If you encounter quality issues with the products received from an SMT manufacturer, take the following steps: - Document the issues with detailed descriptions, photographs, and videos

- Notify the manufacturer of the issues and request an investigation

- Work with the manufacturer to identify the root cause of the issues and develop a corrective action plan

- Negotiate compensation or replacement of the defective products, if applicable

- Consider seeking alternative manufacturers if the issues persist or the manufacturer is unresponsive

Conclusion

Choosing the right SMT manufacturer is critical for the success of your electronic products and business. By following the six proven tips outlined in this article, you can find good SMT manufacturers that meet your quality, delivery, and service expectations. Remember to assess the manufacturer’s experience and expertise, check for quality certifications and standards compliance, evaluate their production capabilities, consider their location and supply chain, assess their customer service and support, and request quotes and samples from multiple manufacturers.

By investing time and effort in the selection process, you can establish long-term partnerships with reliable SMT manufacturers that contribute to your business growth and success. As the electronics industry continues to evolve, having a trusted SMT manufacturing partner will help you stay competitive, innovate faster, and deliver high-quality products to your customers.

No responses yet